An industrial laser engraver is an essential equipment used to mark various products. It is a versatile and efficient tool popular in every industrial application. A computer-controlled mirror called galvo moves the laser beam across the material’s surface. Ultimately, these laser beams create the required results on the surface. Almost all types of materials are applicable under an industrial laser engraver. The most popular materials are metals, plastics, ceramics, and wood.

An industrial laser engraver can mark or engrave a variety of information. This information may include numbers, barcodes, logos, and other designs. However, the industrial laser engraver is prevalent in manufacturing and construction. These machines are specially designed for high-volume productions. They are versatile over various products, parts, and tools. Above all, an industrial laser engraver is used for traceability, identification, and branding. They are famous for their speed and accuracy.

Therefore, an industrial laser engraver is an integral part of the production. Keeping that importance in mind, we have prepared this article. It highlights some of the most popular industrial products that require industrial laser markers. In addition, we will also find some trendy advantages of using industrial laser marking systems.

Application of industrial laser engraver

As mentioned, an industrial laser marker is versatile in a wide range of applications in various industries. Serial numbers, barcodes, and other identifying information on products are prevalent in use. In addition, they are also popular in marking instructions and warnings on machinery and equipment. Manufacturing, construction, automotive, electronics, medical devices, aerospace, and packaging are famous fields. Why is an industrial laser engraver such well-known in the above industries? Industrial laser markers are renowned for their speed, accuracy, and versatility. Above all, an industrial laser engraver is better than any other engraving machine.

Popular industrial Products that require industrial laser engraver

Industrial laser markers are popular in a wide range of applications. Some of the most popular industrial products include:

- Automotive parts:

Engine blocks, transmission gears, fuel injectors, piston rings, crankshafts, alternators. - Electronic components:

Printed circuit boards, semiconductors, microprocessors, memory chips, capacitors, resistors, and connectors - Medical devices:

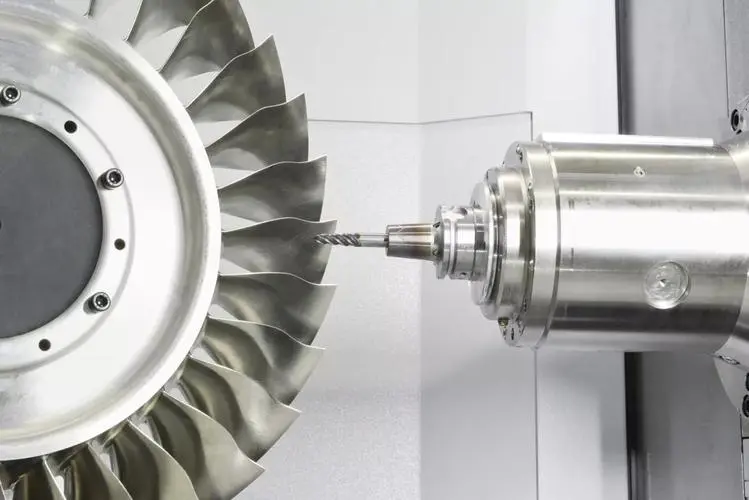

Orthopaedic implants, stents, surgical instruments, endoscopic devices, medical implants, dental implants - Aerospace components:

Airframe components, flight control surfaces, landing gear, engine components, avionics components - Construction and oil gas tools:

Construction equipment, oil and gas drilling, pipelines - Logistics and packaging:

Shipping boxes, pallets, shipping containers, packaging bags, labels, pouches, trays - Metal Parts and components:

Tooling and dies, pipes and tubes, automotive metal parts, medical devices - Industrial machinery and equipment:

CNC machines, lathes, milling machines, grinding machines, welding machines - Plastic Products:

Plastic packaging, sporting goods, consumer products, toys, and games - Wood Products:

furniture, kitchenware, musical instruments, crafts and souvenirs, toys and games

These are the most popular industrial products that require an industrial laser engraver. However, the versatility of this machine allows it to be used in various industries and mark a wide range of products.

The advantages of using a laser engraver in industrial applications

The use of laser marking machines in industrial applications is becoming popular due to their various benefits. Laser engraving machines are highly accurate, safe, fast, versatile, durable, and cost-effective. They are suitable for engraving or marking all sizes of parts and components. They can create all types of designs, including custom designs, logos, barcodes, etc.

This section will discuss various advantages of using laser engravers in industrial applications. We will also find out why it is an essential tool for many manufacturers.

Increased Efficiency

One of the significant advantages of using an industrial laser engraver is its increased accuracy. It isn’t easy to achieve precise and consistent results with traditional engraving methods. In this case, laser engravers use a highly focused beam of light to create precise and accurate engraving. It allows for finer details and intricate designs.

Besides, the increased precision of laser engravers allows for consistent and accurate markings. As a result, it reduces the possible errors and the need for rework. Moreover, increased efficiency can lead to higher productivity and reduced costs in manufacturing. As a result, it opens the possibility of new business opportunities and increases the value of the products.

Increased Accuracy

One of the significant advantages of using an industrial laser engraver is its increased accuracy. It isn’t easy to achieve precise and consistent results with traditional engraving methods. In this case, laser engravers use a highly focused beam of light to create precise and accurate engraving. It allows for finer details and intricate designs.

This property is essential in those applications where precision is a critical concern. Precision is necessary for small parts and components or creating custom designs and logos. Moreover, an industrial laser engraver is an automated computer-programmed system. As a result, it allows for precision engraving with increased productivity and efficiency.

Durability

Durability is another significant advantage of using an industrial laser engraver. A typical industrial laser marking machine uses a focused beam to create markings. There is no physical contact between the engraver and the material. As a result, the used laser engraving machine is not subject to wear and tear caused by friction or abrasion. It is important to note that these wear and tear issues are common if you use traditional engraving methods.

Furthermore, an industrial laser engraver from thunderlaser comes with high-quality and durable components. As a result, it ensures that it can withstand the rigors of industrial use. Therefore, it makes the device reliable and long-lasting for various industrial applications.

Cost-effectiveness

A typical laser engraver machine is more cost-effective than traditional engraving methods. There are several reasons why an industrial laser engraver is a cost-effective solution. The following reasons combined make laser engravers a cost-effective option for industrial needs.

- Low operation cost:

A laser industrial engraving machine require minimal maintenance. In addition, it also eliminates the need for costly replacement parts or tooling. Moreover, a laser engraver has a long lifespan, reducing the ownership cost. - Minimal waste of materials:

A typical laser industrial marking machine doesn’t have to waste money on wasted materials. - Reduces the need for multiple engraving tools:

The industrial laser engraver can engrave all materials. It can also be used in most industrial marking applications. As a result, it reduces the investment cost in multiple engraving tools. - Reduces cost per unit:

An industrial marking machine provides the fastest engraving solution. As a result, it reduces the price per unit and increases overall productivity.

Types of laser markers

The type of industrial laser engraver used in the applications impacts the advantages. It is important to note that each laser marking machine type provides unique features and capabilities. As a result, the choice of which one to use depends on the requirements of the applications. Typically there are five types of industrial marking machine. These types are CO2 laser engraver, Fiber laser engraver, UV laser engraver, Nd: YAG laser engraver, and green laser engraver.

CO2 laser engravers are highly versatile and can engrave almost all materials. As a result, this laser engraver is highly suitable for most industrial applications. On the other hand, Fiber laser engravers and Nd: YAG laser engravers provide better precision. As a result, these laser engravers are suitable for those applications where precision is the prime concern. Furthermore, UV and green laser engravers are famous for their precision and high speeds. This type of laser engraver is suitable for manufacturing small parts and components.

Therefore, the advantages of industrial laser markers will vary based on the type of machine used. In addition, factors such as materials, size, and speed determine which type of industrial laser engraver is the best suited.

Safety and maintenance

These two factors are the most critical considerations for industrial equipment. An industrial laser engraver machine is safe to operate. The laser engraver machine doesn’t produce any dangerous fumes or dust. In addition, a laser engraving process is a non-contact process. Therefore, there is no risk of injury from sharp blades or cutting tools. As a result, industrial laser markers are so famous for rigorous production. Besides, an industrial laser engraver machine has a safety enclosure, making it safe to operate.

In terms of maintenance, industrial laser marking systems require relatively lower maintenance. Above all, a laser engraver machine’s safety and minimal maintenance features make them an ideal choice.

Summary

In industrial applications, a laser engraver can engrave almost all items, including products, parts, or tools. An industrial laser engraver can mark all information, such as serial numbers, barcodes, and logos. It provides a wide range of benefits. The advantages of using a laser machine include high precision, speed, minimal maintenance, and safety.

Thunder Laser is a leading manufacturer of industrial laser markers. The Odin laser engraving machine and Aurora laser marking machine are famous creations from them. However, there are other different models based on different laser power levels. These models are the ideal choice for marking a wide range of materials. These machines can be used on various metal components, electronics and others. Above all, you can create custom designs, logos, and barcodes.

For more information, contact our customer service team. We hope you will get the finest solution from them for your project.

.png) International

International

United States

United States

Brasil

Brasil

Canada

Canada

Costa Rica

Costa Rica

Česká

Česká

Ελλάδα

Ελλάδα

Polska

Polska

Ireland

Ireland

Portugal

Portugal

Lietuva

Lietuva

Россия

Россия Deutschland

Deutschland

Britain

Britain

Україна

Україна

France

France

Sverige

Sverige

Italia

Italia

Norway

Norway

Denmark

Denmark

Romania

Romania

한국

한국

中国

中国

ประเทศไทย

ประเทศไทย

中国香港

中国香港

Israel

Israel

中國臺灣

中國臺灣

India

India

پاکستان

پاکستان

پශ්රී ලංකා

پශ්රී ලංකා

ジャパン

ジャパン

Australia

Australia

New Zealand

New Zealand

South Africa

South Africa