An introduction to laser engraving denim.

Laser engraving denim is an attractive way to personalize your denim products. Moreover, it’s also a very durable option. Laser engraving denim is a new technology that uses laser beams. The laser beam helps to make complicated designs or text on denim fabric.

Fashion designers are also using this method to personalize their denim items. In the laser engraving process, a high-precision laser helps to remove fibers. This method also provides a lasting impression that won’t rub off or peel.

Denim is a versatile and long-lasting fabric that has been a mainstay in the fashion world for a long time. With the development of laser engraving, denim products can now have a unique touch. Laser engraving denim gives you a lot of options. You can also add your name, a special message, or a custom design.

How denim laser engraving machines help manufacturers to increase productivity.

The denim laser engraving machine is a high-tech piece of machinery. These machines are helping manufacturers in several ways. Denim laser machines also use laser technology to create designs on denim fabric. Moreover, it also benefits manufacturers in the fashion and laser jeans denim industry.

- Increased Efficiency:

Denim laser machines’ capacity to boost productivity is a major advantage. Machines can speedily crank out a massive quantity of goods. Laser jeans Manufacturing in a short amount of time also allows for meeting customers’ demands.

- Improved Precision:

The laser beam in the denim laser engraving machines creates a precise design. Moreover, the resulting designs are clear and accurate, producing deep and long-lasting effects. Denim laser machine detailed designs help to create a higher-quality product. Moreover, laser jeans can also help to differentiate the manufacturer from its competition.

- Reduced Labor Costs:

Denim laser engraving machines automate the engraving process. Laser engraving denim machines also reduce the need for manual labor. Manufacturers may see a decrease in their labor costs as a result of this. Laser jeans manufacturers can produce products without the need for manual labor.

- Versatility:

A variety of intricate designs and patterns are suitable for laser engraving devices that work with denim. The automation provides laser jeans manufacturers versatility in the products they can offer. This versatility can attract a broader range of customers. Laser engraving denim can also help manufacturers to stay ahead of the competition.

- Cost Savings:

Denim laser engraving machines offer a cost-effective solution for manufacturers. The machines also cut the need for manual engraving methods. Moreover, reducing the cost of production and allowing manufacturers to produce products.

- Increased Productivity:

Laser engraving denim helps manufacturers produce more goods faster. This increased productivity can also help manufacturers meet their customers’ demands. Moreover, manufacturers can grow their businesses through the laser engraving denim technique.

The process of laser engraving denim

The process of a denim laser engraving machine is a multi-step process. The laser denim technique involves the following steps:

- Design Preparation:

The first step in the laser engraving process is to create a design you want to engrave onto the denim fabric. You can also do this with software for graphic design, like Adobe Illustrator or Corel DRAW. After finishing the design, it needs to convert into a form of a vector file.

- Pre-treatment:

Before the laser engraving process begins, the denim fabric must be pre-treated. Pre-treatment ensures that denim is clean and free of any impurities. The impurities can also interfere with the laser engraving process. This can involve washing the denim fabric using a pre-treatment solution. You can also wipe it down with a clean, dry cloth.

- Positioning:

After the cleaning procedure, the denim fabric becomes ready for laser engraving. Manufacturers always tell us to position fabric on the laser engraving machine’s surface. The fabric should be in place to prevent movement during the engraving process. Any movement can also result in an uneven or distorted final design.

Laser Engraving:

After positioning the denim fabric, the laser engraving process can begin. The laser beam is directed at the denim fabric. Denim laser engraving machine beam energy vaporizes the fabric. The vaporization process leaves behind an engraved design. Laser denim engraving change also helps to achieve different levels of detail engraving.

- Post-treatment:

After completing the laser engraving, manufacturers remove the fabric that must come from the machine. Experts also focus on removing any residue from the laser engraving machine. The procedure involves using a cleaning solution or brushing away any residue. Additionally, experts also apply a protective solution. The solution helps to extend the lifespan of the engraved design.

- Finishing:

Finally, the laser-engraved denim fabric is ready for final finishing. This may involve washing the fabric, pressing it, or applying treatments. The treatments help to produce the desired end product. Once the finishing process is complete, the laser-engraved denim fabric is ready. You can use the designs for various applications, such as clothing, accessories, or home décor.

How Thunder laser engraving denim machines are unique from other engraving machines

Thunder laser engraving machines are unique from other engraving machines. The unique features that make them different from others are as follows.

- Advanced laser technology:

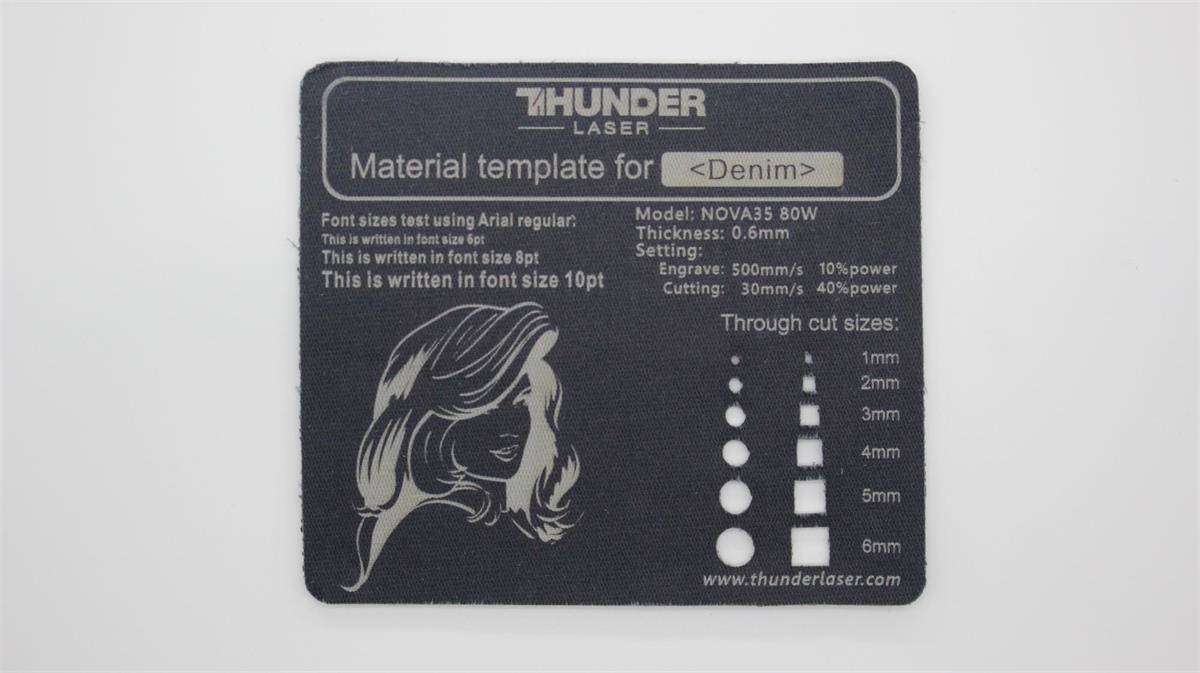

Thunder laser machines use advanced laser technology. The advanced technology includes the use of CO2 lasers. CO2 lasers allow for precision and accuracy in engraving designs onto denim fabric. This technology also provides a wide range of customization options. The denim laser engraving machine allows users to adjust laser parameters. These parameters help to achieve the desired level of detail in the engravings.

- User-friendly software:

Thunder laser machines come with user-friendly software that allows for easy design creation. Moreover, this software also helps to control the laser engraving process. This makes it easy for users to create high-quality designs.

- High-speed engraving:

Thunder laser machines help to engrave designs at high speeds. Denim laser engraving machine also helps to achieve reduced cost results for businesses.

- Wide range of materials compatibility:

Thunder laser machines can engrave designs onto a wide range of materials. The range includes leather, fabric, paper, and more. This makes them a versatile tool for businesses that work with a variety of materials.

- Durable construction:

Thunder laser machines use durable materials and advanced engineering. The advanced tools help to ensure that engraving will withstand heavy use. Moreover, it also provides long-lasting performance.

Conclusion.

In conclusion, denim laser engraving machines are revolutionizing the world of denim design. These machines are also producing a vast range of products. With their precision, speed, and versatility, these machines are helping businesses. Moreover, businesses are creating unique and high-quality products.

Denim laser engraving machines are a game changer in denim design and production. So why wait? Invest in a denim laser engraving machine today and start creating the denim products of your dreams!

.png) International

International

United States

United States

Brasil

Brasil

Canada

Canada

Costa Rica

Costa Rica

Česká

Česká

Ελλάδα

Ελλάδα

Polska

Polska

Ireland

Ireland

Portugal

Portugal

Lietuva

Lietuva

Россия

Россия Deutschland

Deutschland

Britain

Britain

Україна

Україна

France

France

Sverige

Sverige

Italia

Italia

Norway

Norway

Denmark

Denmark

Romania

Romania

한국

한국

中国

中国

ประเทศไทย

ประเทศไทย

中国香港

中国香港

Israel

Israel

中國臺灣

中國臺灣

India

India

پاکستان

پاکستان

پශ්රී ලංකා

پශ්රී ලංකා

Australia

Australia

New Zealand

New Zealand

South Africa

South Africa