Laser Cutter

- Home

- >

- Thunder Laser, Your Best Laser Machine Manufacturer

- >

- Laser Cutter

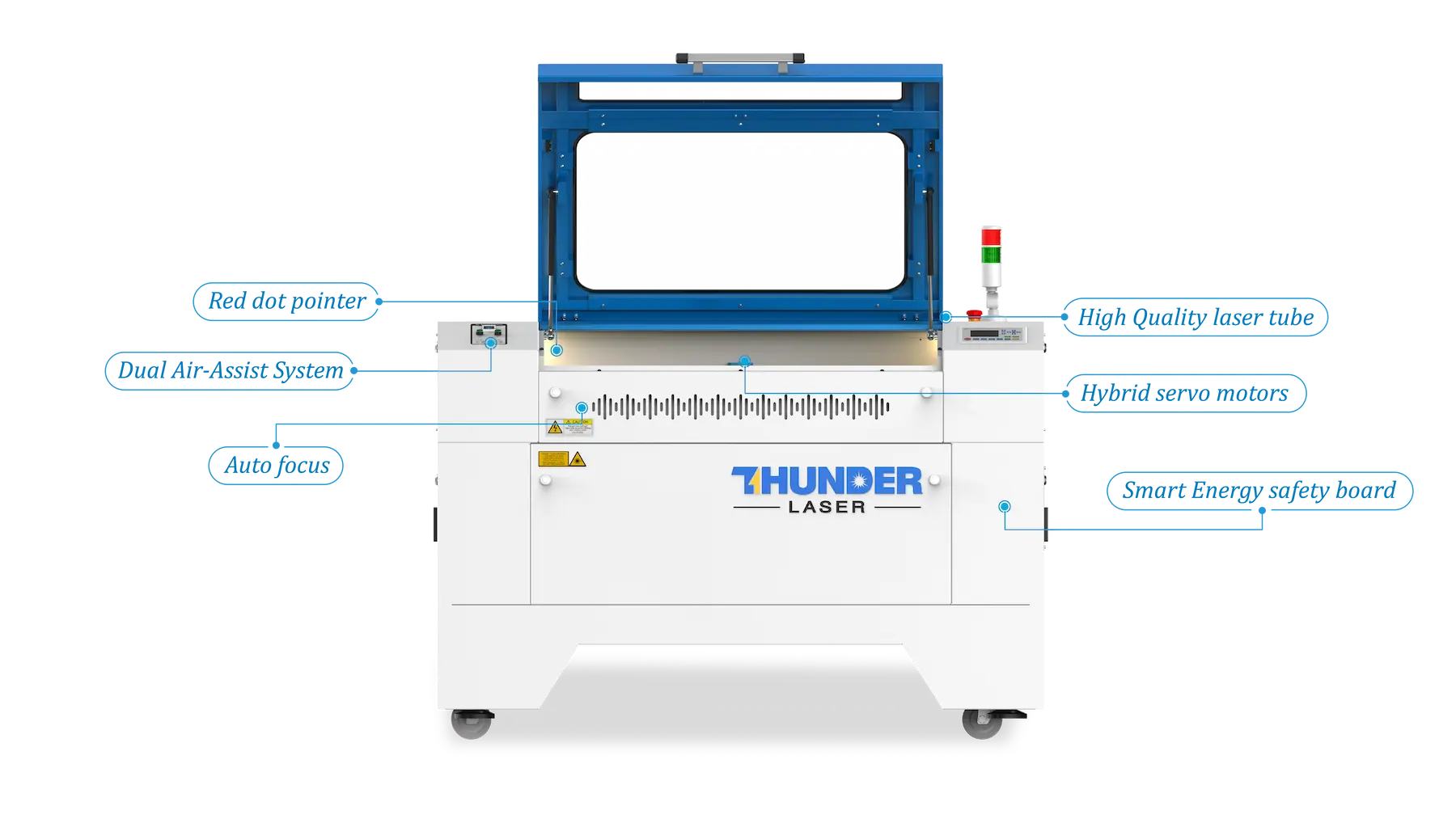

Nova Laser Cutting Machine

Laser Type : DC CO2 glass tube laser

( 100-130W )

( 60W )

( 80-100W )

( 100-130W )

Big to hold Two People

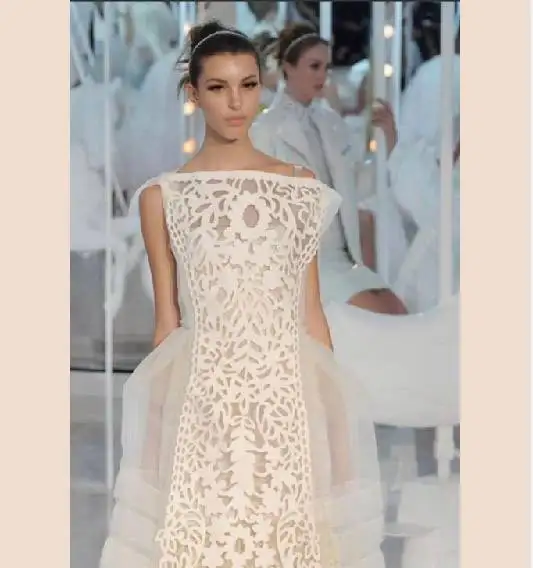

Boost your enterprise-level wood and acrylic cutting with a spacious big laser cutting table.

Achieve top-notch rotary engraving on larger laser units.

You can make more laser produces for increased productivity and bulk production capabilities with Nova laser cutting machine.

Cutting 20mm+ thick large Sign, You can do it

When working with thick materials, higher power and faster speed translates to cleaner, smoother edges with minimal burrs.

For laser cutting materials 20mm or thicker, consider a laser cutter with a recommended power of over 60W.

Thunder Nova Laser cutting machine, The best laser cutter.

Acrylic Laser cutting with Thunder Laser Nova 35

2 x 2cm <5min

High-end Engraving

Thunder Laser

Epilog

1. Premium laser tubes and components

2. Expert installation technology

3. Exceptional dimming systems

4. Patented exhaust systems for efficiency

5. Rigorous light quality testing

6. Extensive laser cutting and carving tests—over 5 times

That’s why Nova laser cutting machine engraves so accurately, clearly, and cleanly.

Ready to learn more?

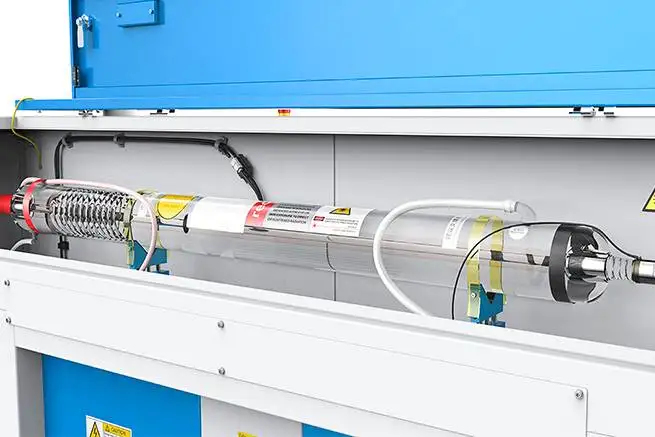

Powerful co2 laser tube

CO2 laser tubes deliver greater laser power options compared to diode lasers, expanding your material choices for your enterprise.

Thunder guarantees the selection of top-notch CO2 laser tubes with stable and consistent light output, achieved through rigorous testing, accurate light path control, and over 5 cutting and carving trials.

This is the main key Nova laser cutting machine can quickly laser carve and cut high-quality products

Hybrid servo motor

Stands out with its advantages of lightning-fast speed of up to 1000mm/s and stable movement frequency.

Stability means high quality, which is also the second key Nova laser cutting machine can quickly laser carve and cut high-quality products.

Plus, it boasts impact protection and high safety, ensuring not be easily damaged by flying debris.

The second key Nova laser cutting machine can quickly laser carve and cut high-quality products

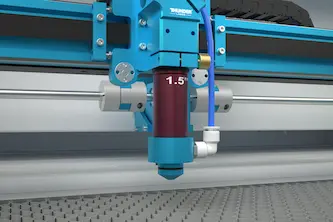

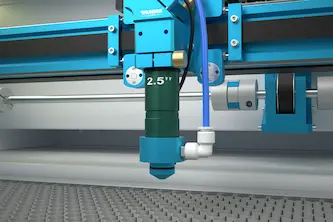

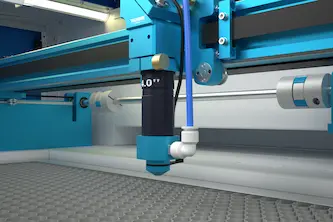

Dual air assist patent

Unlike single air assist, Thunder introduces a dual air assist system with both high and low-pressure options.

Activate high-pressure air assist for comprehensive burning, neat and clean edges during laser cutting.

When laser carving, low-pressure air assist automatically kicks in, ensuring precise fine lines without overheating or fire risks.

This is the third key Nova laser cutting machine can quickly laser carve and cut high-quality products

Green exhaust system

Thunder laser Nova machines are smart. They only start pumping when they’re in action, preventing unnecessary power consumption.

Nova’s ingenious exhaust system can simultaneously exhaust gases up and down, protecting both lenses and materials from being polluted by smoke and dust generated during laser processing.

That is the last key Nova laser cutting machine can quickly laser carve and cut high-quality products

More laser advantages, More possibilities...

The through-door feature facilitates large-scale laser carving and cutting, making your projects more accessible.

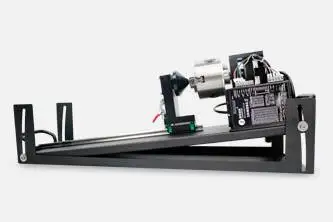

Compatibling with rotary sculpted surface products like tumblers.

Enabling stunning 3D relief engraving.

Laser 3D relief engraving

Create Tank Vehicles with Laser

Make money with laser cutter

laser cut keychain batching

Your harvest is our greatest Happiness

Ready? Get an Available Status Now

We will be happy to help you all your questions

1.How is laser generated?

Laser, a form of high-energy, high-power light, possesses the magical ability to incise objects—much like the magical act of burning paper with a magnifying glass in the sunlight.

The birth of lasers, however, involves a more intricate process. Once the laser machine springs to life, the material within the laser tube oscillates and engages in a chemical reaction, leading to a particle number reversal and finally laser generation.

This newborn laser journeys through a light refraction system before emanating from the laser head. It dances upon the material’s surface, and finally achieve the effect of laser cutting or carving.

2.How does laser work to cause cutting?

At the outset, as the laser machine springs to life, the laser head gracefully glides along the automated guide rail.

Simultaneously, the laser, born within the laser tube, converges through the laser head, crafting a high-power density laser beam that bathes the material.

This infusion of laser energy triggers a rapid surge in material temperature. In the wake of this thermal embrace, the material succumbs, melting and transforming into vapor, creating a seam.

The molten seam finds liberation as auxiliary gas quickly blow it away. Meanwhile, the laser head maintains its graceful progress, etching the path of a precise cut.

3.Diode laser vs CO2 laser?

The diode laser machine has limited power and speed, and its advantage is that it can engrave metal, but it cannot cut and engrave transparent acrylic. Often compact in size, Suitable for learners and beginners.

On the other hand, CO2 laser machines are the hallmark of efficiency and quality in laser processing. Tailored for enterprises and discerning laser enthusiasts, they epitomize the high-end spectrum of laser technology. They belong to the enterprise type laser machine.

4.About after-sales service

Mature shipping chain:

We have local warehouses and it only takes one month from placing an order to receiving the laser machines. In the future, there will be more local warehouses around the world. If you share the same interests as us, we look forward to your joining.

Afraid of learning:

No career is easy, but as long as you decide, we will accompany you to solve all laser problems during the process. Laser Training is our top priority, with most of the technology, continuous learning resource output, and a professional laser technology research department.

Warranty period:

2-year warranty.

Lightburn Software:

Support Lightburn which is a powerful laser Software with its intuitive interface, direct laser control, and strong community support

More support:

Excellent laser video training

Powerful Laser Software Support

Explore Thunder Laser Cutter in Depth

Dual Air Assist system

There’re 2 modes for air assist. Cut and Engrave. The 2 air solenoids are controlled with the smart board. There are also 2 needle valves mounted on the front left panel so you can adjust the flow for each mode as well as momentary push buttons to test the flow. When you press a button the corresponding stage activates for 10 seconds.....

Quick Accurarte Autofocus

In order to achieve the best cutting result by wood laser cutting machine, we will make the laser beam focus when it contact the material on laser cutter engraver, and the smaller laser beam, the better performance. Auto focus function can move up and down the working table to make sure the most proper distance between the material and the focal lens.

By using the auto focus function of acrylic laser cutter, users can focus quickly and accurately before cutting and engraving which saves the time of cutting and engraving and brings the better cutting engraving result.

Red dot pointer

As we know co2 laser is invisible, we cannot get the position of laser dot while laser engraving machine working. However, we need to know the accurate position before dealing with the material most of the time, then how can we achieve it? The special red dot pointer of Thunder Laser engraver cutter can help you to solve this problem. Thunder Laser engraver cutter use a special laser beam combiner to combine the 650nm wavelength of red light and the 1064nm wavelength of co2 laser engraving cutting machine into one path so the invisible co2 laser becomes visible. The red dot pointer helps you to clear the accurate laser position before cutting and engraving, to greatly reduce the deviation and to save your time and material waste.

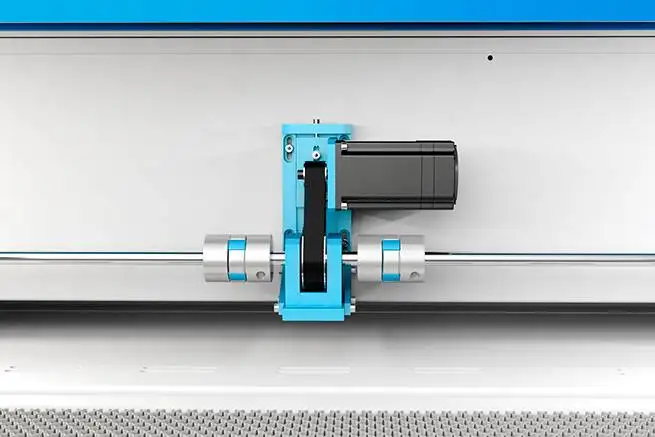

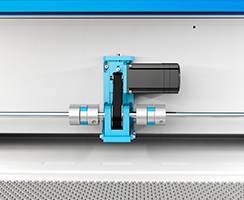

Hybrid Servo Motor

Thunder Laser cutting machine use the Hybrid servo motor. This motor works with low noise and high speed.Meanwhile it has the impact protection and high security to work stable. The more important thing is that this motor can provide very fast acceleration and through the closed-loop control it can make sure the high speed working without losing steps, which can greatly increase the working efficiency of the laser machine.

High Quality laser tube

Every laser tube must pass the strict quality control test before installed on the Thunder laser cutting machine. After finished assembling the laser cutting machine, we will make many tests of cutting and engraving to further make sure the working quality and stability of laser cutting and engraving machine. After these tests, the low quality laser tube with bad laser beam, unstable laser output power, and slow response to switch would be ruled out. That’s why Thunder Laser cutting machine can send out the more refined laser dot and offer the more delicate cutting engraving effect.

Smart Energy safety board

Smart board is used to control exhaust fan, air pump and alarm lamp while laser working.

The smart board is specially designed by Thunder Laser to automatically control the on/off of exhaust fan and air pump according to the need of the laser work.

It facilitates energy saving and noise reduction. Meanwhile, colors of alarm lamp are also controlled by it to show the working state of the laser.

Technical Data

Compatible Materials

Technical Data

Laser System |

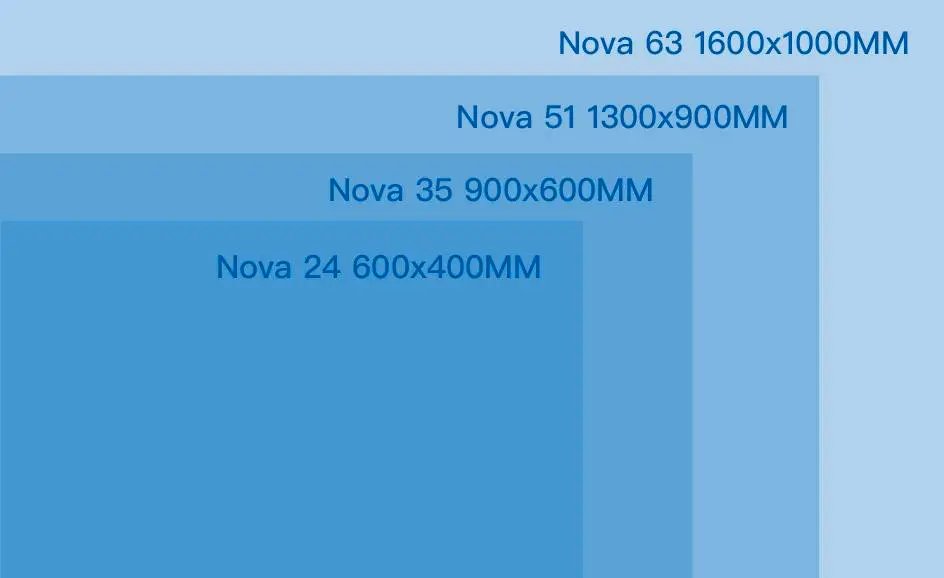

NOVA 24 | NOVA 35 | NOVA 51 | NOVA 63 | |

Laser Tube Wattage |

40-60Watt | 80-100Watt | 100-130Watt | 100-130Watt | |

Work Area |

600x400mm(23.6″ x 15.7″) | 900x600mm(35.4″ x 23.6″) | 1300x900mm(51.2″x35.4″) | 1600x1000mm(63.0″x39.4″) | |

Max Part Size (WxLxH) |

Front door closed | 615x470x155mm(24.2″ x 18.5″ x8.3″) | 931x651x225mm(36.6″ x 25.6″ x8.9″) | 1331x955x225mm(52.4″ x 37.5″ x8.9″) | 1631x1055x225mm(64.2″ x 41.5″ x8.9″) |

| Pass-through door | 610x∞x20mm(24″ x ∞” x 0.79″) | 960x∞x20mm(37.7″ x ∞” x0.79″) | 1360x∞x20mm(53.5″ x ∞” x0.79″) | 1660x∞x15mm(65.3″ x ∞” x0.59″) | |

Table Size |

600x500mm(25.2″ x 19.6″) | 991x691mm(39″ x 27.2″) | 1391x995mm(54.7″ x39.1″) | 1691x1095mm(66.5″ x 43.1″) | |

Z Axis Height |

155mm(6.1″) | 225mm(8.9″) | 225mm(8.9″) | 225mm(8.9″) | |

Dimensions(WxDxH) |

1100x805x645mm(43.3″ x 31.6″ x 25.3″) | 1500x1105x1100mm(59.1″ x 43.5″ x43.3″) | 1900x1405x1100mm(74.8″ x 55.3″ x43.3″) | 2200x1505x1100mm(86.6″ x 59.3″ x43.3″) | |

Net Weight |

141kgs(310lbs) | 311kgs(685lbs) | 431kgs(950lbs) | 470kgs(1038lbs) | |

Max. Speed |

39″/sec. (1000 mm/sec) | ||||

Standard Head |

2.0″ (50.8mm) | ||||

Cooling |

Water Cooled | ||||

Motion Control System |

High-Speed Hybrid servo motors | ||||

Maximum Speed |

1000mm/S(39.4 IPS) | ||||

Speed and Power Control (engraving depth) |

Computer or manually controlled speed and power from 0-100%. Vector color mapping sets speed and power settings using RGB color mapping. | ||||

Operating Modes |

Optimized raster, vector, and combined mode | ||||

Resolution(DPI) |

User-controlled from 100 to 500DPI(standard laser head), up to 1000 DPI(HR head) | ||||

Computer Interface |

Ethernet and USB Connection | ||||

Compatible Operating Systems |

Windows XP/2000/Vista/7/8/10,macOS | ||||

Buffer Memory |

1GB Standard | ||||

Display Panel |

3.5″ LCD panel showing current file, total working time, laser power, speed, etc. | ||||

Electrical Requirements |

110 to 240 volts, 50 or 60 Hz, single phase | ||||

Ventilation System |

Integral exhaust fan. There is 1 output port, 24/35:150mm,51/63:200mm in diameter in the rear of the case. | ||||

Compatible Materials

| Material | Engrave | Cut | Material | Engrave | Cut |

| Wood | √ | √ | Rubber | √ | √ |

| Acrylic | √ | √ | Wood Veneer | √ | √ |

| Delrin | √ | √ | Fiberglass | √ | √ |

| Cloth | √ | √ | Plastic | √ | √ |

| Leather | √ | √ | Cork | √ | √ |

| Mat Board | √ | √ | Corian | √ | √ |

| Melamine | √ | √ | Twill | √ | √ |

| Paper | √ | √ | Anodized Aluminum | √ | × |

| Mylar | √ | √ | Painted Metals | √ | × |

| Pressboard | √ | √ | Tile | √ | × |

| Glass | √ | × | Stainless Steel | * | × |

| Coated Metals | √ | × | Brass | * | × |

| Ceramics | √ | × | Titanium | * | × |

| Marble | √ | × | Bare Metal | * | × |

Optional Accessories but Better Work

Rotary Axis

1.5 Laser Head

2.5 Laser Head

4’’ Laser Head

Gas Air Compressor

Lightburn Software

CCD Camera

Lightburn Cam Kits

.png) International

International

United States

United States

Brasil

Brasil

Canada

Canada

Costa Rica

Costa Rica

Česká

Česká

Ελλάδα

Ελλάδα

Polska

Polska

Ireland

Ireland

Portugal

Portugal

Lietuva

Lietuva

Россия

Россия Deutschland

Deutschland

Britain

Britain

Україна

Україна

France

France

Sverige

Sverige

Italia

Italia

Norway

Norway

Denmark

Denmark

Romania

Romania

한국

한국

中国

中国

ประเทศไทย

ประเทศไทย

中国香港

中国香港

Israel

Israel

中國臺灣

中國臺灣

India

India

پاکستان

پاکستان

پශ්රී ලංකා

پශ්රී ලංකා

Australia

Australia

New Zealand

New Zealand

South Africa

South Africa