Home » Laser engraver materials » Laser Cut Foam: Unlocking Your Creativity with Foam

Laser Cut Foam: Unlocking Your Creativity with Foam

Can you laser cut foam?

Laser foam has become the go-to solution for precision and innovation across multiple industries. EVA foam, with its remarkable shock-absorbing, sound-insulating, and thermal-insulating properties, has transformed the world of sports equipment, household appliances, fitness gear, shoes, and crafts.

The fusion of these two materials unleashes a world of opportunities, making them an ideal choice for sports equipment, household appliances, printing, fitness gear, shoes, and crafts. Laser machine is the best tool to laser cut foam.

Eva foam or polyurethane foam, which one is better?

Now, let’s tackle the question of whether to choose EVA foam or Polyurethane foam for your laser-cut foam projects. While these materials may appear similar, they serve different applications in the world of laser workmanship.

EVA foam, lightweight, flexible, and non-toxic, is the ideal choice for creative projects like crafts, role-play props, and packaging. On the other hand, Polyurethane foam, known for its durability and wear resistance, is more suited for industrial and commercial applications such as insulation, protective packaging, and even house heating solutions.

When it comes to laser cutting foam, EVA foam has more advantages than Polyurethane Foam. It requires lower power settings, resulting in cleaner cuts and reduced heat accumulation compared to Polyurethane foam.

Where to buy?

-

1. Uline

A popular choice for many, Uline offers a variety of laser-cut foam sheets and materials to cater to your needs. Explore their selection here

-

2. Polymershapes

With 80 stores across the United States, Polymershapes provides a wide range of foamboard and paperboard options, ideal for laser-cut foam projects. Check out their offerings here

-

3. Foam factory

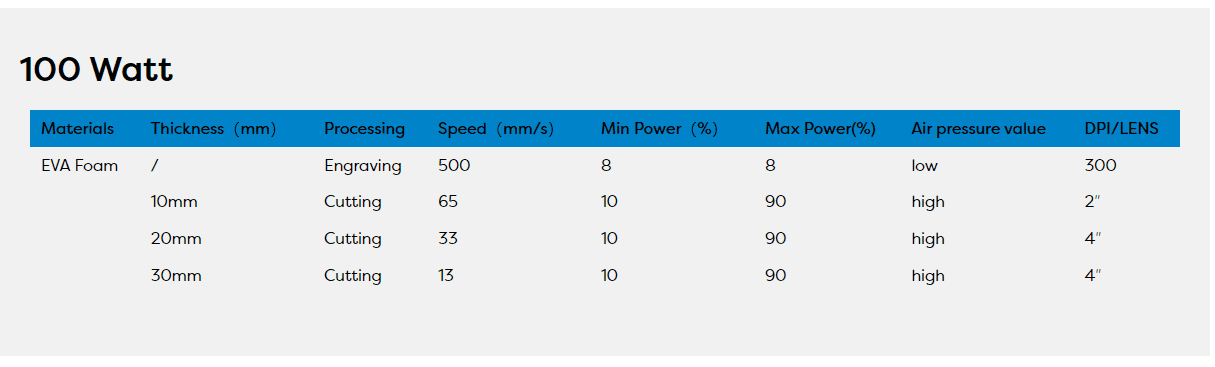

Common parameter for laser foam

Now, let’s delve into the specifics of laser cutting EVA foam. Keep in mind that the cutting outcome can vary based on the foam’s origin, batch, and production method. Here are some general parameters to get you started, but you may need to fine-tune them for your specific laser-cut foam project.

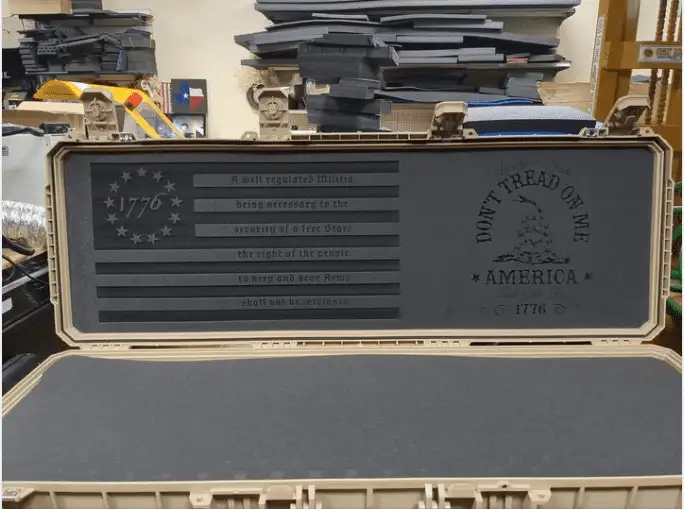

laser cut and engrave eva foam

Choosing a perfect laser foam cutter to laser cut foam

To choose the perfect laser model for your laser-cut foam project, consider the Thunder Laser Nova and Odin series.

Thunder Laser Nova excels in sheet cutting due to its larger laser power and processing platform.

In contrast, Thunder Laser Odin stands out in sheet carving with ultra-high processing speed and precise laser control.

The choice depends on the focus of your laser-cut foam project.

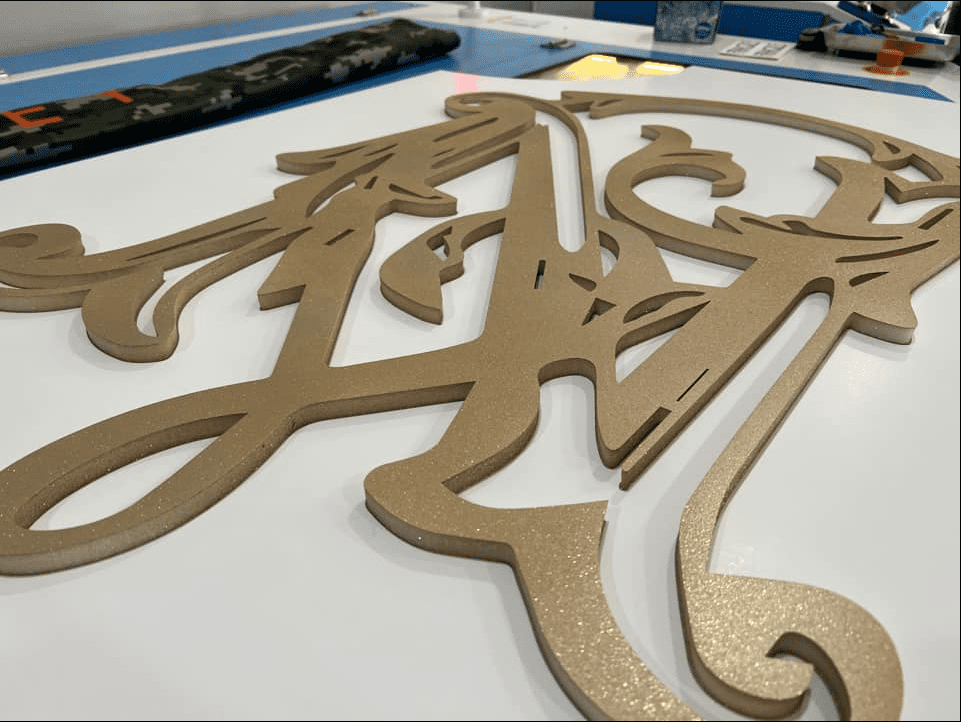

Laser cut foam with these techniques

How to fix eva foam?

Tips for laser engraving foam

- Select high-resolution images for engraving.

- Adjust laser settings, including power, speed, and frequency, to achieve the desired engraving depth and clarity for your laser-cut foam.

- Clean the EVA foam surface before carving to avoid interference from dirt and debris.

- Use cover tape on the surface to prevent discoloration or burning during the laser cut foam process.

- Always run a test to preview the results, and avoid excessive laser power, as it can cause melting or burning of the foam surface.

Take care when laser cutting eva foam

How to store eva Foam?

Lastly, when it comes to storing EVA foam sheets for your laser-cut foam projects, keep them in a room-temperature, well-ventilated, and dry environment. Avoid exposing them to direct sunlight, heat sources, or humid areas.

With these insights and a bit of creativity, you’re well on your way to becoming a master of laser-cut foam projects. Unleash your imagination and create stunning, intricate designs with this incredible material!

Call us at 86 181 0304 3363 to speak to one of our professionals, or email us at [email protected] / [email protected].

We stand ready to help you find the system that works for you !

.png) International

International

United States

United States

Brasil

Brasil

Canada

Canada

Costa Rica

Costa Rica

Česká

Česká

Ελλάδα

Ελλάδα

Polska

Polska

Ireland

Ireland

Portugal

Portugal

Lietuva

Lietuva

Россия

Россия Deutschland

Deutschland

Britain

Britain

Україна

Україна

France

France

Sverige

Sverige

Italia

Italia

Norway

Norway

Denmark

Denmark

Romania

Romania

한국

한국

中国

中国

ประเทศไทย

ประเทศไทย

中国香港

中国香港

Israel

Israel

中國臺灣

中國臺灣

India

India

پاکستان

پاکستان

پශ්රී ලංකා

پශ්රී ලංකා

Australia

Australia

New Zealand

New Zealand

South Africa

South Africa