Effects of Laser Processing on Different Materials

Differences in Processing Effects of Different Materials

In laser processing, some materials are suitable for high-definition engraving, while others are suitable for making stamps. Different materials will exhibit different effects during laser processing, suited for various purposes. Here, we introduce the processing effects of some commonly used materials.

Basswood Board

Basswood board is one of the most commonly used materials in laser processing, and laser processing will produce a light yellow to brown carbonization effect. Basswood boards have excellent applications in photo engraving, vector engraving, and other techniques.

Double-Colored Board

The coating on the surface of the double-colored board will be removed during laser engraving, creating a high-contrast effect. Black-bottomed white-faced double-colored boards are particularly suitable for engraving high-precision photos.

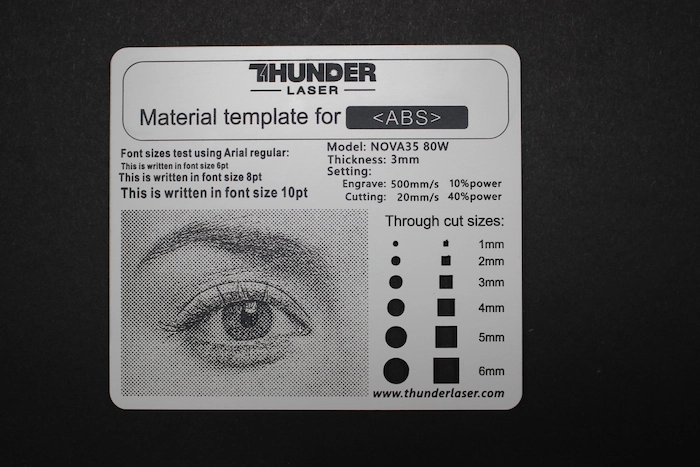

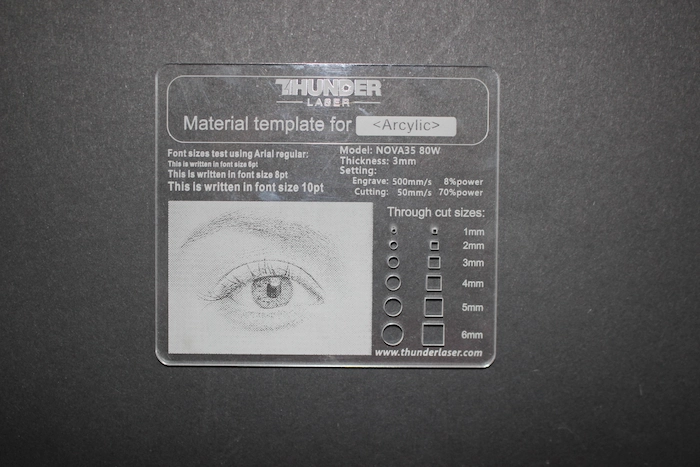

Acrylic

The parts of acrylic engraved by laser will turn white, presenting a simple and unique style on the transparent substrate. When combined with a light stand, a unique decorative style can be achieved.

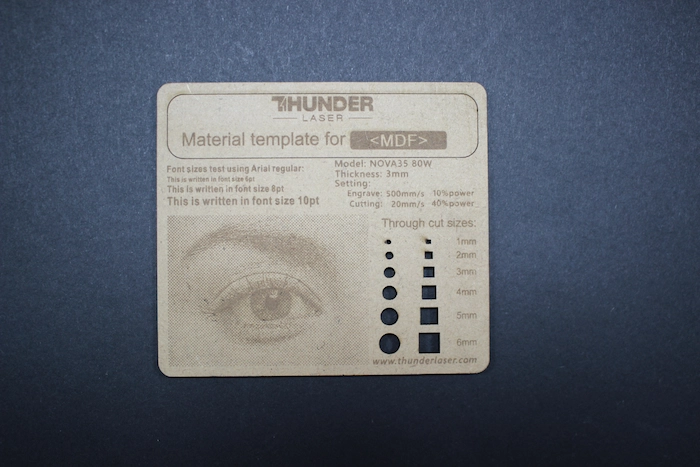

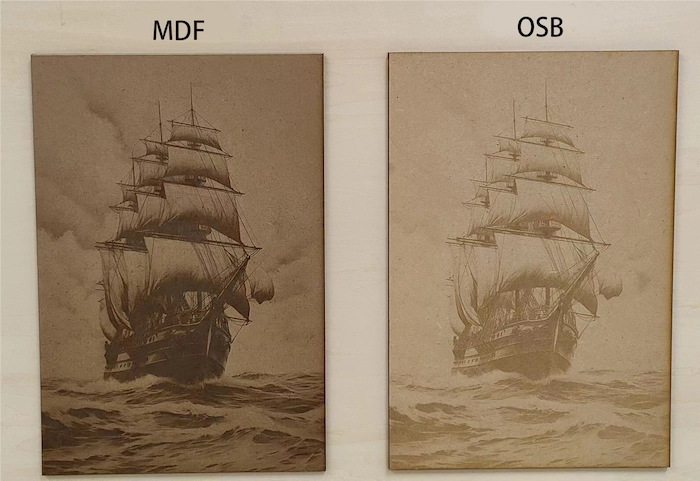

Medium-Density Fiberboard (MDF)

MDF is one of the most commonly used materials in laser processing, and laser processing will produce a brownish-black carbonization effect. When used for photo engraving, vector engraving, and other techniques, MDF can exhibit an advertising poster-like effect.

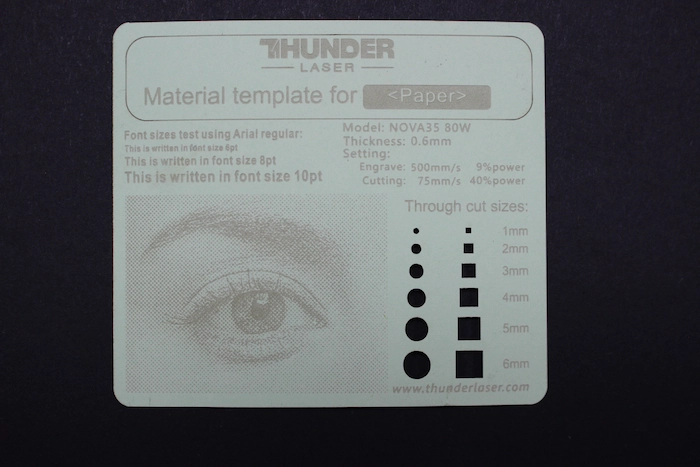

Green Cardboard

Green cardboard can be laser processed, producing a grayish-black carbonization effect.

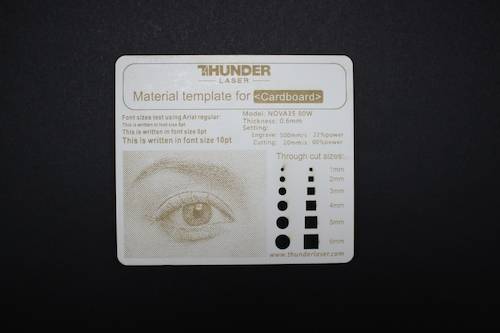

Thick Cardboard

Thick cardboard can be laser processed, producing a golden-brown carbonization effect.

Tech Fabric

Tech fabric can be laser processed, producing a grayish-brown carbonization effect.

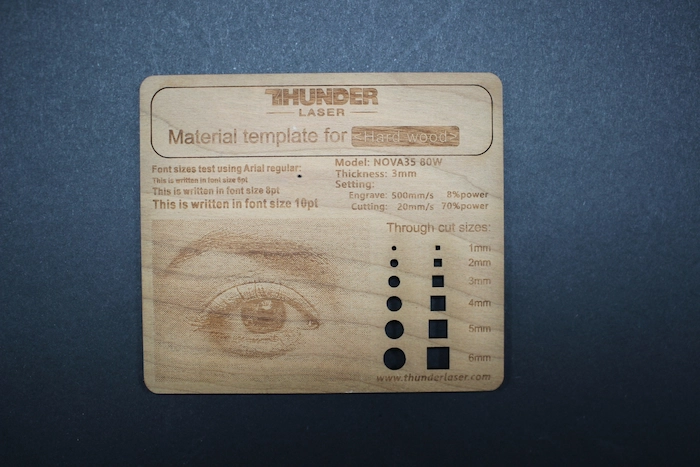

Solid Wood Board

Solid wood board is one of the most commonly used materials in laser processing. Depending on the type of wood, laser processing will produce carbonization effects of varying depths. Solid wood boards have distinct wood grains and a unique natural style, which have excellent applications in photo engraving, vector engraving, and especially relief engraving techniques.

Oka Board

Oka board can be laser processed, creating a high-contrast effect. It can be used for engraving high-precision photos.

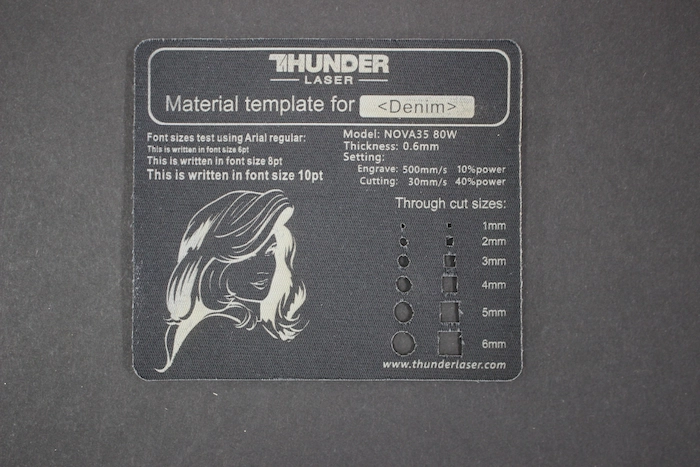

Denim

Denim can be laser processed for engraving images, but it is not suitable for engraving high-precision photos.

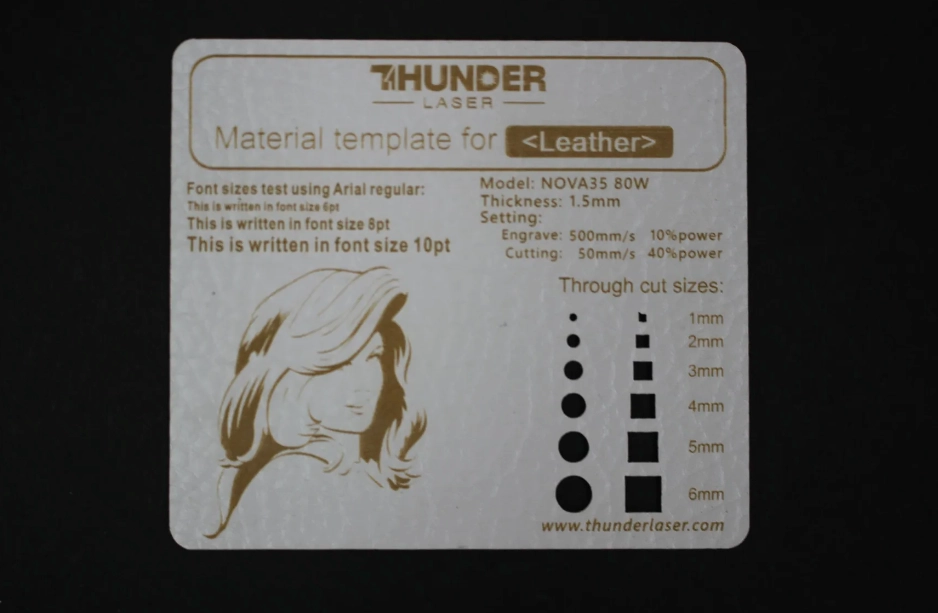

Leather

Leather can be laser processed for engraving images, but it is not suitable for engraving high-precision photos.

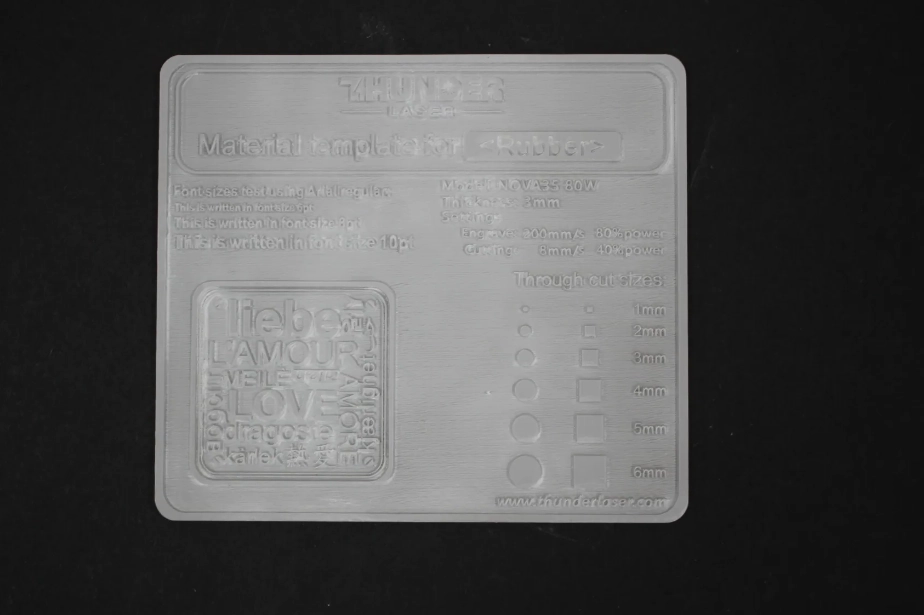

Rubber Pad

Rubber pads can be laser processed and are relatively suitable for making stamps, but not as good as other materials for engraving images.

Add Your Heading Text Here

Even for the same material, differences in sub-types can lead to significant variations in effects. For example, while both are acrylic, the engraving effect of extruded acrylic is dull and uneven, whereas the engraving effect of cast acrylic appears bright and evenly white. This is due to the different manufacturing processes for cast acrylic and extruded acrylic, resulting in different presentations during laser processing.

Similarly, while both are fiberboards, the engraving effect of MDF is relatively darker, while the engraving effect of oriented strand board (OSB) is brighter. This is because the wood particles that make up MDF and OSB come from different tree species.

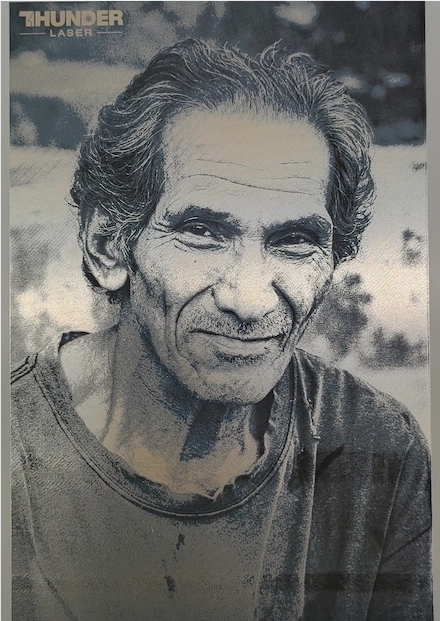

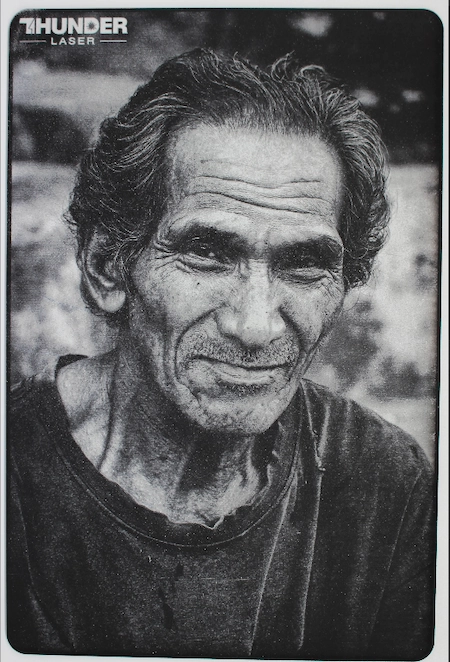

Differences in Processing Effects of Different Batches of Materials

Even for the same sub-type of material, subtle differences in raw material composition, quality, manufacturer, and batch can lead to significant variations in effects. Below are the effects of engraving the same image on black-bottomed white-faced double-colored boards from the same manufacturer but different batches. Image A shows a double-colored board with a slightly thicker coating, resulting in a more pronounced metallic color in the engraved photo and unclear image quality. Image B shows a double-colored board with a thinner coating than the one on the left, resulting in a clear, high-contrast engraved photo.

.png) International

International

United States

United States

Brasil

Brasil

Canada

Canada

Costa Rica

Costa Rica

Česká

Česká

Ελλάδα

Ελλάδα

Polska

Polska

Ireland

Ireland

Portugal

Portugal

Lietuva

Lietuva

Россия

Россия Deutschland

Deutschland

Britain

Britain

Україна

Україна

France

France

Sverige

Sverige

Italia

Italia

Norway

Norway

Denmark

Denmark

Romania

Romania

한국

한국

中国

中国

ประเทศไทย

ประเทศไทย

中国香港

中国香港

Israel

Israel

中國臺灣

中國臺灣

India

India

پاکستان

پاکستان

پශ්රී ලංකා

پශ්රී ලංකා

ジャパン

ジャパン

Australia

Australia

New Zealand

New Zealand

South Africa

South Africa