- Author: Cathy

A metal engraving machine offers exceptional precision and durability, making it ideal for applications ranging from industrial identification to custom metalwork. Whether you’re working with stainless steel, aluminum, or brass, selecting the right metal engraving machine is crucial for achieving sharp, long-lasting marks.

In this article, you’ll learn about the main laser types, critical machine features, and practical considerations to help you choose the most suitable solution for your metal engraving projects.

1. Can a Laser Machine Engrave Metal?

Yes, a metal engraving machine can engrave metal, but the type of laser matters. It allows for precise and detailed designs on a variety of metals, making it an ideal choice for both industrial applications and creative projects.

According to the statistics report, the Laser Marking Market size is estimated at USD 3.91 billion in 2024, and is expected to reach USD 5.18 billion by 2029.

Whether for marking or engraving, laser machines offer speed, accuracy, and the ability to handle complex patterns with minimal effort. It you’re interested in metal engraving, choosing a suitable metal engraving machine is important.

2. Different Laser Types for Metal Engraving Machine?

- Diode Laser

Suitability: Produce different colors of light, with blue diodes offering higher power output than red and green ones. However, they are generally insufficient for metal engraving and are only suitable for coated surfaces or softer materials.

Advantages: Affordable and accessible, making them a good entry-level option for beginners.

Limitations: Lack the power required for most metal engraving tasks, leading to shallow or unclear results on metals.

- CO2 Laser

Suitability: Primarily for non-metal materials but can engrave coated metals using a marking spray.

Advantages: Versatile for various materials, including wood, acrylic, anodized aluminum and coated metals.

Limitations: Less effective on most bare metals without additional treatment, requiring more setup for metal engraving.

- UV Laser

Suitability: Best suited for marking and micro-engraving on metals, especially for fine details or sensitive materials.

Advantages: High precision with minimal heat impact, preventing damage to delicate metal surfaces. Work well on various materials including non-metallic materials like glass, ceramics.

Limitations: Less effective for deep engraving and typically more expensive.

- Fiber Laser

Suitability: Best suited for metal engraving, offering high precision and deep engraving on a wide range of metals like stainless steel, aluminum, and brass.

Advantages: Fast, accurate, and capable of handling complex designs. Ideal for industrial use and high-volume production.

Limitations: Typically more expensive but offers long-term value.

How to Choose the Right Laser Size for Metal Engraving

The size of the laser you need to engrave metal depends on several factors, including the type of metal, the complexity of the design, and the scale of your project. Generally:

Power Output: For effective metal engraving, a fiber laser with at least 20W to 50W is recommended. Higher wattage provides faster engraving and deeper marks, especially on harder metals like stainless steel. Diode lasers are typically too low-powered for effective metal work.

Work Area Size: Consider the size of the objects you plan to engrave. A laser machine with a work area that fits your largest project piece is ideal. Common sizes range from 100mm x 100mm to 300mm x 300mm for standard projects.

3.What Can You Create with a Metal Engraving Machine?

Metal is a commonly used material across various industries, and laser engraving on metal is naturally widely applied. You can customize existing items with laser engraving, or directly create artworks through the laser engraving process.

Various Industries

- Automotive industry

- Aerospace industry

- Metal fabrication and manufacturing

- Custom metal jewelry

- Metal signage and plaques

- Artistic metalwork

Various products

- Knife Decoration

- Personalized Wallet Card

- Tumbler

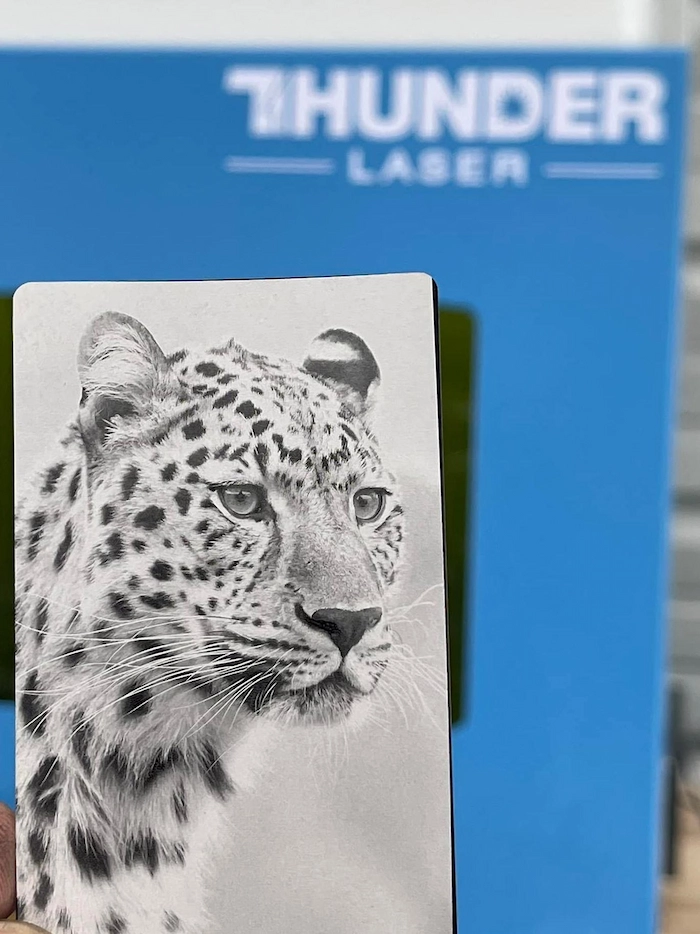

- Photo Engraving

4. How to Choose a Laser Metal Engraving Machine?

When selecting a laser metal engraving machine, it’s important to consider several factors that will influence the effectiveness, quality, and cost of your work. Here’s a guide to help you make the best choice.

4.1. Understand Material Compatibility

4.2. Evaluate the Laser Machine

4.3. Set a Budget

4.4. Consider User Feedback

4.5. Plan for Future Needs

How Much is a Metal Laser Engraving Machine?

The cost of a laser engraver for metal can vary widely depending on the laser type, power, brand, and features. Here’s a general price range:

Diode Laser: Typically the most affordable, starting around $300 to $1,000, but they are generally not suitable for engraving bare metal.

CO2 Laser: It can range from $2,000 to $20,000 or more, but they usually require a marking spray to engrave metal.

Fiber Laser: It can range from $5,000 to $50,000 or more. Lower-wattage models are on the lower end, while high-power, industrial-grade machines are on the higher end.

UV Laser: Typically more specialized and expensive, ranging from $15,000 to $70,000, due to their precision and ability to engrave delicate materials.

5. What Is the Best Laser Engraving Machine for Metal?

Both UV and fiber lasers are well-suited for metal engraving, and you can choose a laser engraver that uses either as its laser source. The key difference lies in their wavelengths.

UV lasers have a shorter wavelength, making them more suitable for marking and micro-engraving non-metal materials with high precision. However, due to their lower energy output, UV lasers are less effective for deep engraving on metals. If your work involves light engraving on metals as well as detailed work on non-metal materials, a UV laser might be the right choice for you.

On the other hand, if your primary focus is metal engraving, a fiber laser would be the optimal choice. The higher wavelength of fiber lasers is well absorbed by metals, making them ideal for deep and precise metal engraving. Fiber lasers are versatile and can handle a wide range of metals, meeting diverse laser metal engraving needs.

What Metal Can Fiber Lasers Process?

- Stainless Steel

- Carbon Steel

- Aluminum

- Brass

- Copper

- Platinum

- Nickel

- Cobalt

- Titanium

- Gold

- rubber

- Silver

- Chrome

- Iron

- Magnesium

- ...

Choose Thunder Laser Metal Engraving Machines!

Advantages of Thunder Laser Machines

High Precision

Capable of engraving complex patterns;

High DPI resolution for crisp markings;

Consistent output to ensure uniform quality

Low Maintenance

Over 100,000 hours of operational life;

No regular replacements like CO2 laser tubes;

Dust-proof design to reduce maintenance needs

User-Friendly

Compatible with software like LightBurn

Automatic focusing for precise setup;

Touchscreen interface for easy control

Energy Efficiency

Lower power consumption for cost savings;

Air-cooled systems to reduce energy use;

Eco-friendly with minimal energy waste

The Thunder Aurora provides both fiber and UV options, making it a high-quality, high-precision metal laser engraver. With its speeds up to 8000mm/s, the powerful Aurora supports your business in a compact desktop size.

Features like auto-focus and a light camera make it easy to use, enabling faster and more convenient metal engraving customization.

It excels at precise laser marking, while its high power also enables deep engraving. With the Aurora, your metal engraving business will truly stand out.

CO2 lasers are not particularly suited for processing most metals, but they can engrave coated or painted metals, anodized aluminum, or metals treated with marking compounds.

Primarily used for non-metal materials, Nova offers speeds of up to 1000mm/s. It also features a large working area, supporting bulk or large-scale material customization.

Some customers choose the Nova for engraving coated metal cups, allowing it to play a role in light metal engraving as well.

6. Thunder Laser Parameter for Laser Metal

The following are the parameters for Thunder Laser Aurora-Lite-50W on different metal for reference. It’s advisable to conduct small-scale tests and adjust parameters accordingly for your specific needs.

| Materials | Marking Result | Speed(mm/s) | Power(%) | Frequency(KHz) | Fill Mode | Line Interval(mm) | No. of Passes |

|---|---|---|---|---|---|---|---|

| 304 Stainless Steel | Black | 200mm/s | 10% | 100KHz | Bi-directional | 0.02mm | 10 |

| White | 1700mm/s | 20% | 50KHz | CrossHatch | 0.02mm | 1 | |

| Carbon Steel | Black | 100mm/s | 10% | 50KHz | CrossHatch | 0.02mm | 1 |

| White | 400mm/s | 20% | 60KHz | Bi-directional | 0.02mm | 1 | |

| Brass | Black | 100mm/s | 50% | 50KHz | Bi-directional | 0.02mm | 1 |

| White | 400mm/s | 30% | 50KHz | Bi-directional | 0.02mm | 1 | |

| Aluminum | White | 3500mm/s | 80% | 50KHz | Bi-directional | 0.02mm | 1 |

| Gold | White | 1000mm/s | 35% | 50KHz | CrossHatch | 0.02mm | 3 |

Conclusion

Choosing the right metal laser engraver depends on your specific goals—whether it’s precision marking or deep engraving on hard surfaces. By understanding the differences between laser types and machine capabilities, you can make a more informed decision. With the proper laser metal engraver, achieving high-quality results on metal is entirely achievable.

FAQs About Laser Metal Engraving Machine

Q1. Does laser engraving metal wear off over time?

No, laser engraving is a permanent process. Since the design is etched or engraved into the metal’s surface, it will not fade or wear off, making it ideal for industrial and identification applications.

Q2. What maintenance does a laser metal engraving machine require?

Routine maintenance includes cleaning the lens, checking the focus, and ensuring the air assist and cooling systems function properly. Fiber lasers typically require less maintenance than CO₂ lasers due to fewer moving parts.

Q3. How do I clean the engraved metal surface after marking?

After laser engraving, you can clean the metal surface using a mild detergent or specialized cleaner, often combined with a soft cloth or brush. Remember not to scratch or damage the engraved area while cleaning.

Q4. Can I engrave curved or cylindrical metal items?

Yes, with the help of a rotary attachment, laser engravers can accurately mark cylindrical items like rings, tumblers, and pipes by rotating them during the process.

Q5. How do I avoid heat distortion during laser engraving on metal?

To prevent heat distortion, it’s important to use lower power settings, ensure consistent cooling, and use air assist. You should also engrave in multiple passes if deep marks are needed on thicker materials.

- Tags

#metal engraver, #laser engraver for metal, #metal laser engraving machine, #fiber laser, #uv laser, #metal engraving, #co2 laser, #laser marking

.png) International

International

United States

United States

Brasil

Brasil

Canada

Canada

Costa Rica

Costa Rica

Česká

Česká

Ελλάδα

Ελλάδα

Polska

Polska

Ireland

Ireland

Portugal

Portugal

Lietuva

Lietuva

Россия

Россия Deutschland

Deutschland

Britain

Britain

Україна

Україна

France

France

Sverige

Sverige

Italia

Italia

Norway

Norway

Denmark

Denmark

Romania

Romania

한국

한국

中国

中国

ประเทศไทย

ประเทศไทย

中国香港

中国香港

Israel

Israel

中國臺灣

中國臺灣

India

India

پاکستان

پاکستان

پශ්රී ලංකා

پශ්රී ලංකා

ジャパン

ジャパン

Australia

Australia

New Zealand

New Zealand

South Africa

South Africa