The Impact of Laser on the Fabric

- Home

- >

- Choose by Industries

- >

- The Impact of Laser on the Fabric

The first piece of clothing was made of natural elements, and later humans invented weaving, spinning. After the invention of the sewing machine, machines greatly liberated human labor. The market prospects of the clothing industry are very broad, and laser machines will be another new technology to help the clothing industry develop rapidly.

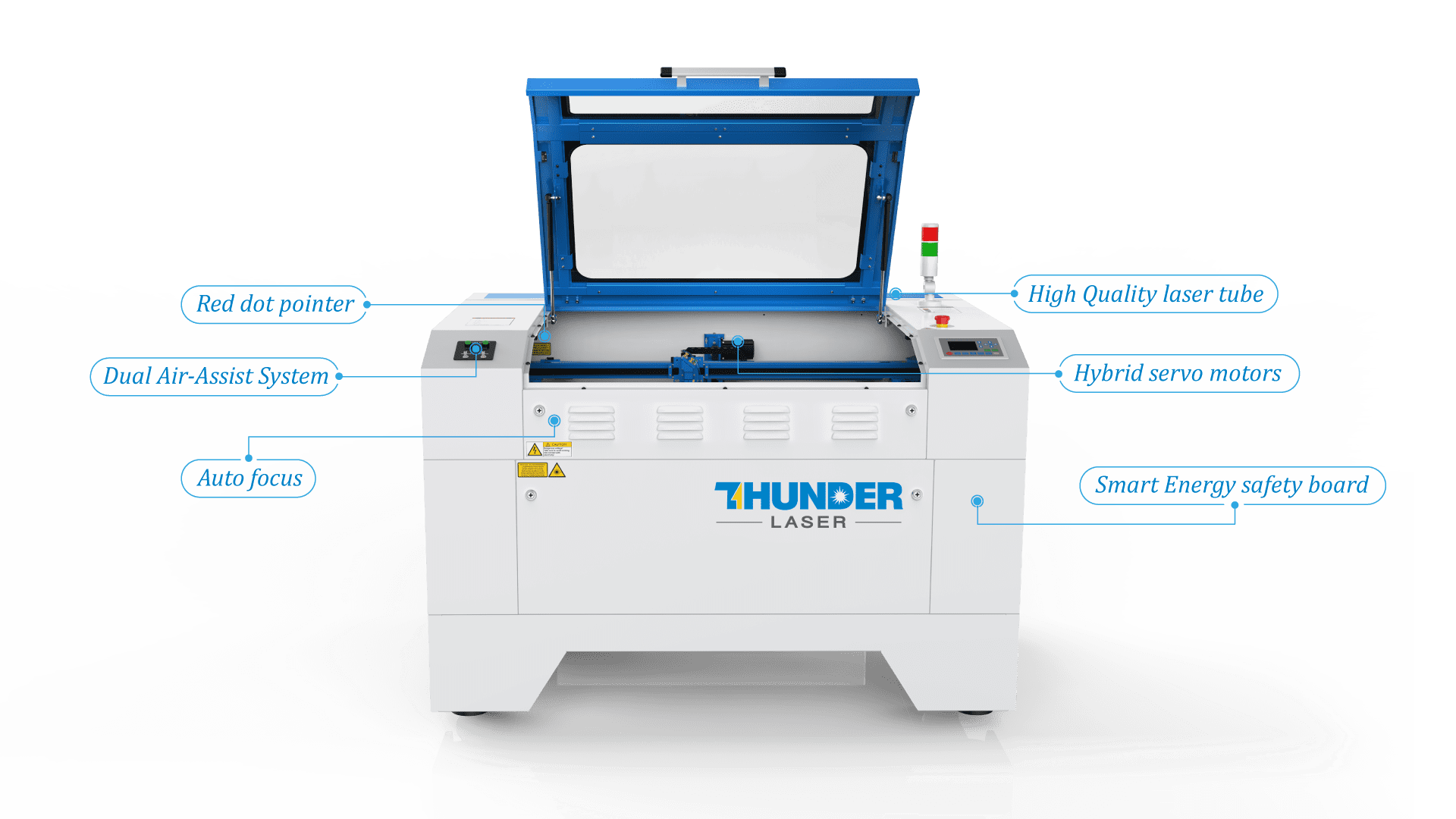

This article will explore the application of laser machines, such as the fabric laser cutting machine and leather laser engraving, in clothing manufacturing and design, emphasizing their impact on creativity, efficiency, and sustainability.

Applications of Laser Technology in Clothing

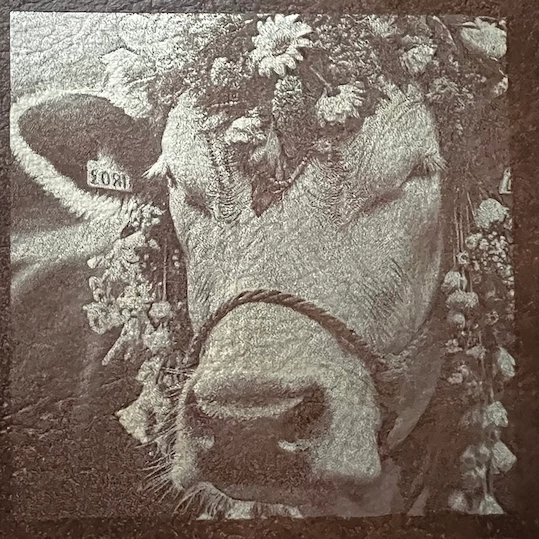

Laser Cutting and Marking of Leather Fabrics

Denim Laser Spray Carving

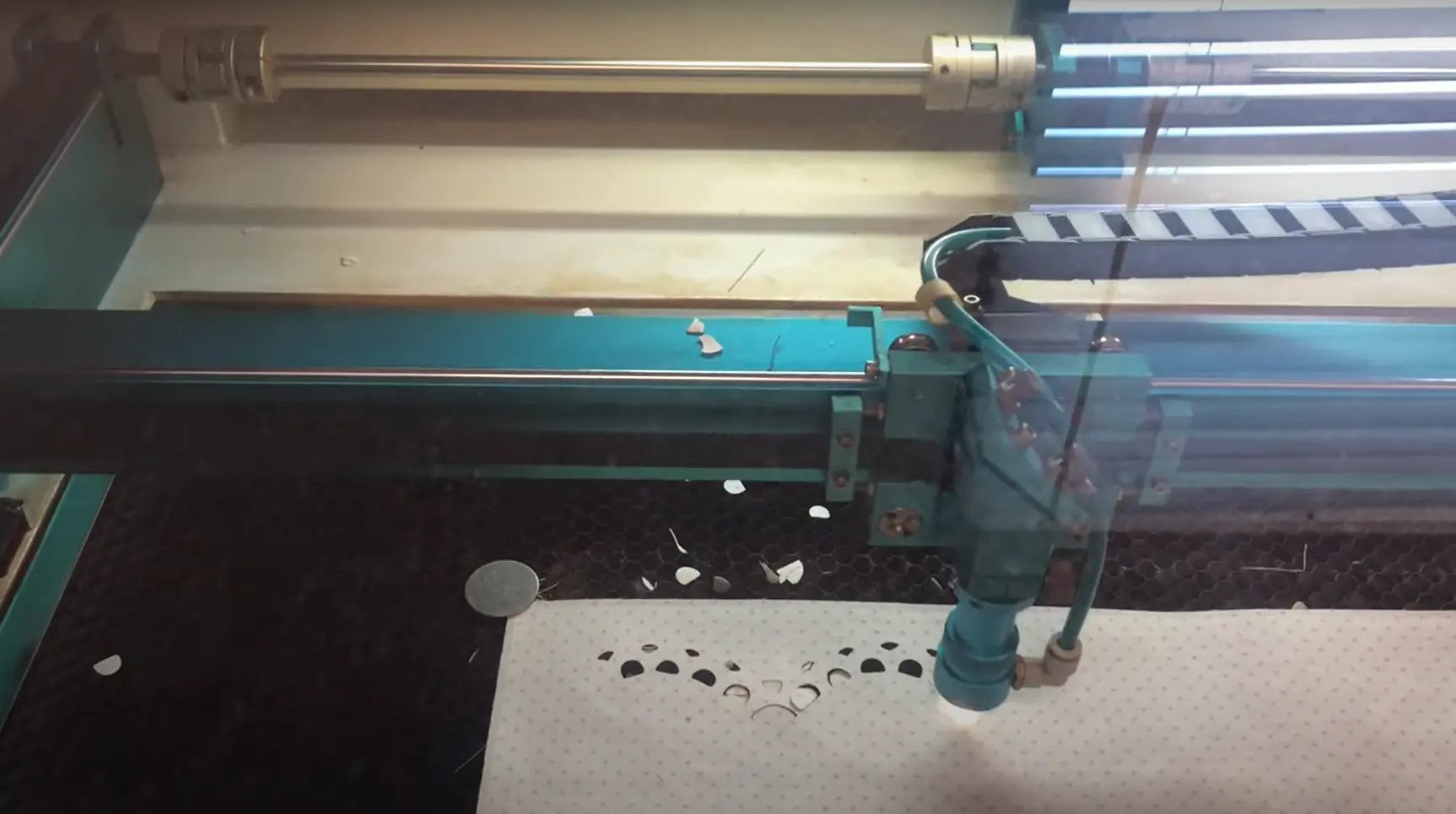

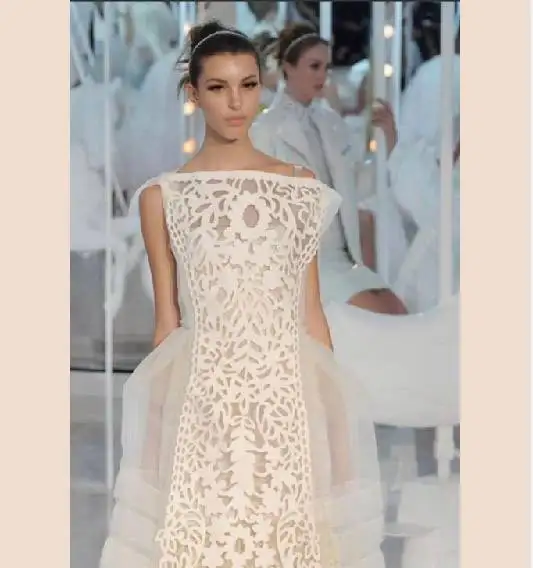

Laser Fabric Cutting

Laser Embroidery

Advantages of Laser Machines in the Clothing Industry

1. Flexible, Non-Contact Processing for Improved Quality

2. High-Speed Cutting for Increased Efficiency

3. Precision Cutting Across Various Fabrics

4. Simplified Processes with Enhanced Pattern Effects

How to avoid uneven fabric on the platform?

How to better laser engrave denim?

The Future of Laser Technology in Fashion

1. Laser-Activated Textures

2. Mass Customization and Personalization

3. Integration with Artificial Intelligence

4. Innovation in Fashion Accessories

Conclusion

Join the laser revolution in advertisement

Call us at 86 181 0304 3363 to speak to one of our professionals, or email us at [email protected] / [email protected].

We stand ready to help you find the system that works for you !

.png) International

International

United States

United States

Brasil

Brasil

Canada

Canada

Costa Rica

Costa Rica

Česká

Česká

Ελλάδα

Ελλάδα

Polska

Polska

Ireland

Ireland

Portugal

Portugal

Lietuva

Lietuva

Россия

Россия Deutschland

Deutschland

Britain

Britain

Україна

Україна

France

France

Sverige

Sverige

Italia

Italia

Norway

Norway

Denmark

Denmark

Romania

Romania

한국

한국

中国

中国

ประเทศไทย

ประเทศไทย

中国香港

中国香港

Israel

Israel

中國臺灣

中國臺灣

India

India

پاکستان

پاکستان

پශ්රී ලංකා

پශ්රී ලංකා

ジャパン

ジャパン

Australia

Australia

New Zealand

New Zealand

South Africa

South Africa