Compared with auto focus, manual focus has the advantages of being faster and can be used in more flexible scenarios.

Manual focus does not require a dedicated manual focus button. It needs rather a focal stick.

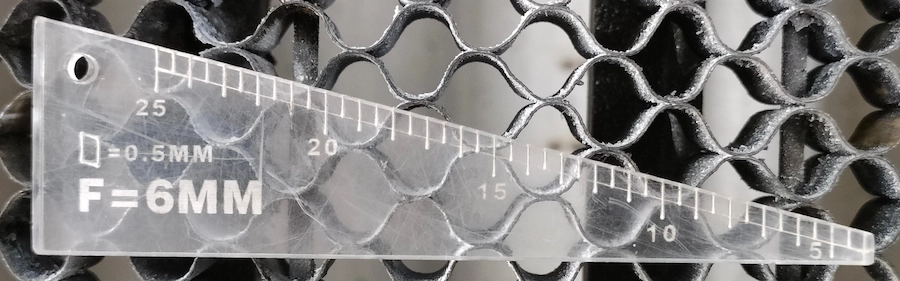

What’s a Focal Stick?

Focal stick is a triangle with measurements, usually made of durable 5mm acrylic.

How to Use the Focal Stick?

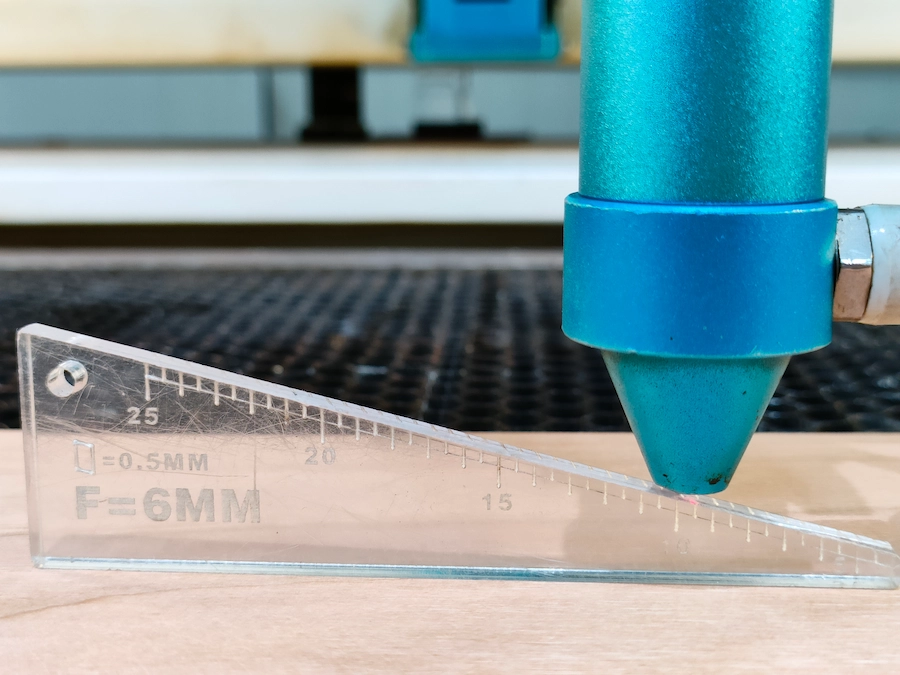

For 2″ laser head, the focal stick should be used by placing its longer right-angled edge on the material and adjusting the nozzle to touch the 5mm scale.

And there is another quicker way: flat your focal stick on the material, and adjust the nozzle to touch the 5mm stick’s surface.

Adjusting the nozzle to 5mm

Adjusting the nozzle to the flat stick

For 4″ laser head, the focal stick should be used by placing its longer right-angled edge on the material and adjusting the nozzle to touch the 10mm scale.

For objects processed with the rotary, check that the object is leveled first. Then select the focus method based on the laser head model.

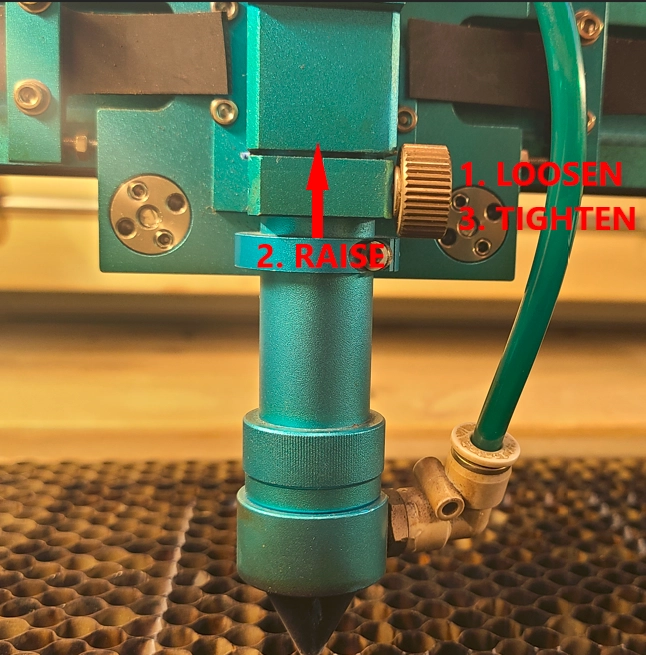

How to Adjust the Focal Stick?

1. If you need to add or remove the rotary or replace the laser head, raise or lower the plate to the proper position.

2. Put the material in the right place, then put the focal stick on the material.

3. Loose the brass knob, let your laser head and nozzle touch the focal stick. Tighten the knob as it’s adjusted.

When to use Manual Focus:

1. Rotary jobs – The shape of the rotary machine and tumblers do not work with the sensors. So it’s time for manual focus to come in handy.

2. If not using the stock 2″ head. Manual Focus can work with the 4″ laser head, which auto focus can’t do.

3. Odd shaped objects that have varying thicknesses or are warped\wavy. Using manual focus in the local area you wish to engrave is a nice choice.

4.The material is transparent, such as clear cast acrylic. Infrared light of auto focus passes through transparent materials and does not work, while while manual focus works fine.

5.When you need to control the distance of defocus, let the nozzle hit the scales on manual stick.

6.Other cases when the sensors are misaligned or not functioning correctly.

.png) International

International

United States

United States

Brasil

Brasil

Canada

Canada

Costa Rica

Costa Rica

Česká

Česká

Ελλάδα

Ελλάδα

Polska

Polska

Ireland

Ireland

Portugal

Portugal

Lietuva

Lietuva

Россия

Россия Deutschland

Deutschland

Britain

Britain

Україна

Україна

France

France

Sverige

Sverige

Italia

Italia

Norway

Norway

Denmark

Denmark

Romania

Romania

한국

한국

中国

中国

ประเทศไทย

ประเทศไทย

中国香港

中国香港

Israel

Israel

中國臺灣

中國臺灣

India

India

پاکستان

پاکستان

پශ්රී ලංකා

پශ්රී ලංකා

Australia

Australia

New Zealand

New Zealand

South Africa

South Africa