Laser Engraving Aluminum

- Home

- >

- Laser engraver materials

- >

- Laser Engraving Aluminum

Outline

Can you laser engrave aluminum?

Anodized aluminum, as you know an etched surface material when Laser etching aluminum. It is all about adding a touch of magic to metal surfaces. It involves creating a protective layer that thickens aluminum oxide, preventing further oxidation. This protective layer consists of a metal middle, an outermost oxide film, and a clever blockage layer between the metal and oxide. Its main mission? To shield the metal and keep it looking sharp.

But here’s the twist: laser etching aluminum takes anodized aluminum to a whole new level. Traditional anodized aluminum marking might weaken the product’s structure and make it a pain to clean. The laser, on the other hand, comes to the rescue. It’s like a superhero for aluminum, with a fine laser beam that can create ultra-fine markings, superb clarity, precision, and unwavering performance.

What types of aluminum can be laser engraved?

Anodized aluminum

Bare aluminum

Painted or powder-coated aluminum

What kind of laser do you need to engrave aluminum?

Fiber lasers

CO2 lasers

CO2 lasers are more suitable for anodized aluminum and coated aluminum, which has a protective oxide layer. While CO2 lasers cannot effectively engrave bare aluminum, they can interact with the anodized coating. The laser removes the top layer, revealing the shiny aluminum underneath and creating a contrasting design. This method is particularly effective for applications where color contrast is desired, as the engraving exposes the aluminum’s natural sheen against the colored anodized surface.

What can you make with laser engraved anodized aluminum?

- business card

- invitations

- bracelet

- wedding advertising board

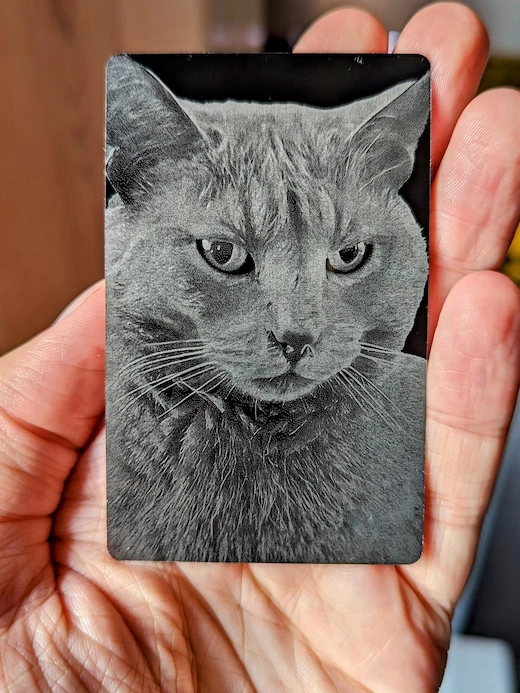

- photo engraving

- tumbler

What are the settings for laser engraving aluminum?

How much laser power to engrave aluminum?

To effectively engrave aluminum, a laser power of 30 to 100 watts is generally recommended, depending on the thickness and desired depth of the engraving.

Fiber lasers are often used for aluminum engraving and typically operate in the range of 20 to 50 watts for fine details, while higher wattage can achieve deeper engravings more quickly.

CO2 lasers can also engrave anodized aluminum but usually require a higher power level (around 60 to 100 watts) for effective results, especially on thicker materials.

Recommended parameters for laser engraving aluminum

| Laser source | Material | Speed(mm/s) | Frequency(KHz) | Power(%) | Bidirectional or not | Air pressure value | No. of passes | DPI |

|---|---|---|---|---|---|---|---|---|

| Fiber lasers - 50w | aluminum sheet | 3500 | 50 | 80 | double | / | 1 | / |

| CO2 lasers-80w glass tube | anodized aluminum | 1000 | / | 50 | / | low | / | 350 |

Find more creative laser aluminum videos here!

Laser engraving aluminum ideas

How to achieve crisp lines when laser engraving aluminum?

- It's crucial to optimize your laser settings, including power and speed, to prevent over-melting while ensuring sufficient energy for precise engraving.

- Use a well-focused beam and high-quality vector files for intricate designs.

- Consider multiple light passes instead of a single heavy one, and select an aluminum alloy suitable for fine engraving.

- Employing air assist can help cool and clean the engraving area, further enhancing line crispness.

How to darken laser engraving on aluminum?

To darken laser engraving on aluminum, several effective methods can be employed. Start by adjusting your laser settings to increase power and decrease speed, which can create deeper, darker engravings. Experiment with multiple passes to achieve the desired depth and darkness.

Consider using a marking spray or cermark-type product specifically designed for metal engraving, which can be applied before laser treatment to produce darker, more contrasted results.

Another option is to oxidize the engraved area using a chemical solution, which can darken the engraved portions significantly. Some engravers have success with anodizing the aluminum after engraving, as this process can enhance the contrast between the engraved and non-engraved areas.

For a more natural approach, you can try heat-treating the engraved area with a torch, which can darken the metal through controlled oxidation.

How to paint fill engraved aluminum?

Paint filling engraved aluminum can enhance visibility and appeal by creating contrast between the design and surface. Additionally, it provides some protection, resulting in a more professional finish.

First, thoroughly clean the engraved surface using isopropyl alcohol to remove any oils or debris. Next, choose a paint suitable for metal surfaces, preferably an enamel or epoxy-based paint for durability. Apply the paint generously over the engraved area, ensuring it fills all the grooves. You can use a small brush, squeeze bottle, or even your finger to work the paint into the engraving.

Allow the paint to dry slightly, but before it fully sets, use a lint-free cloth or paper towel to wipe away the excess paint from the surface, leaving it only in the engraved areas. For a cleaner finish, you can use a plastic scraper or credit card to remove excess paint. If needed, use a cotton swab dipped in paint thinner to clean up any remaining paint outside the engraving.

For added protection and a professional finish, consider applying a clear coat over the entire surface once the paint has fully cured. This method creates a striking contrast between the painted engraving and the aluminum surface, enhancing the visibility and aesthetic appeal of your engraved design.

Pick up an aluminum laser engraver for you!

When it comes to choosing the right laser engraver for your laser etching aluminum project, our NOVA series, BOLT series, and Aurora series can all meet your needs.

Need a big processing platform? Go for the Thunder Laser Nova. It supports batch and large-volume processing with its huge working area and pass-through doors, capable of efficiently engraving anodized aluminum with CO2 laser. Revealing a small message, the Nova 35 is the most affordable choice.

Thunder Laser Bolt uses an RF laser tube, excelling in finer engraving effects. It can also engrave tumblers and will have superior carving effects compared to Nova.

Finally, our fiber laser marker named Thunder Laser Aurora is your go-to for small-scale aluminum oxide products like business cards. In addition to anodized aluminum, it can also directly process aluminum sheets. It will be your best choice for marking most metals including aluminum.

- Tags

.png) International

International

United States

United States

Brasil

Brasil

Canada

Canada

Costa Rica

Costa Rica

Česká

Česká

Ελλάδα

Ελλάδα

Polska

Polska

Ireland

Ireland

Portugal

Portugal

Lietuva

Lietuva

Россия

Россия Deutschland

Deutschland

Britain

Britain

Україна

Україна

France

France

Sverige

Sverige

Italia

Italia

Norway

Norway

Denmark

Denmark

Romania

Romania

한국

한국

中国

中国

ประเทศไทย

ประเทศไทย

中国香港

中国香港

Israel

Israel

中國臺灣

中國臺灣

India

India

پاکستان

پاکستان

پශ්රී ලංකා

پශ්රී ලංකා

ジャパン

ジャパン

Australia

Australia

New Zealand

New Zealand

South Africa

South Africa