Laser Engraving Stone: A Comprehensive Guide

- Home

- >

- Laser engraver materials

- >

- Laser Engraving Stone: A Comprehensive Guide

Outline

Can a laser engrave stone?

Yes, laser engraving works well on various types of stone including granite, marble, slate, and sandstone to create permanent marks, designs, text, and images on the surface. Laser engraving stone provides an incredible range of design options. The laser beam interacts with the stone surface to create contrast and depth, making it ideal for creating memorial markers, decorative pieces, signage, and architectural elements.

Laser engraving on stone is precise and offers high-quality results, though the effectiveness can vary depending on the stone type and laser settings used.

Can laser cutters cut stone?

What laser engraved stone can you create?

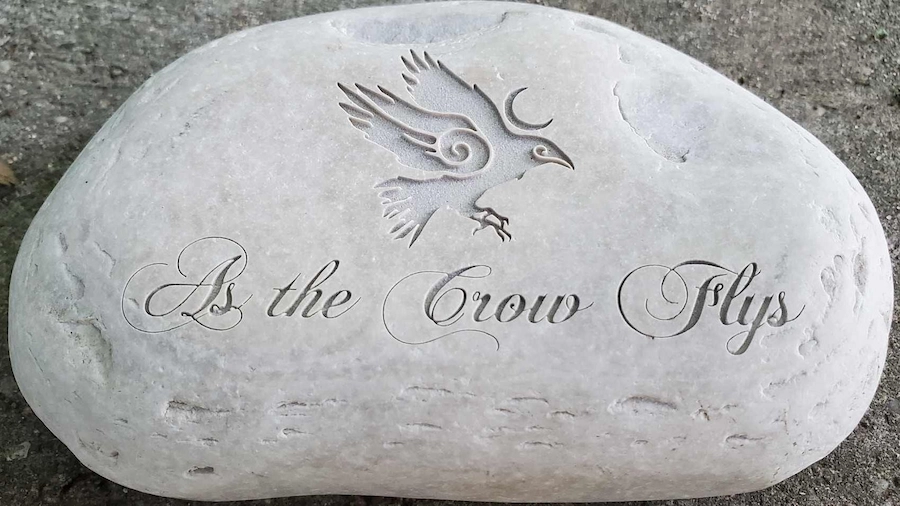

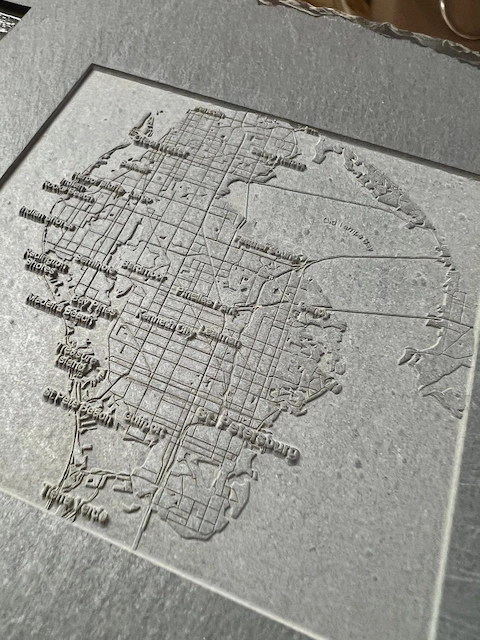

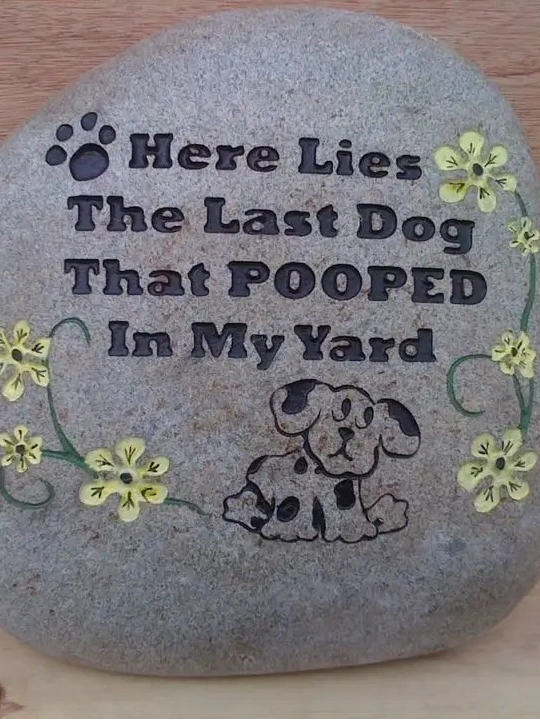

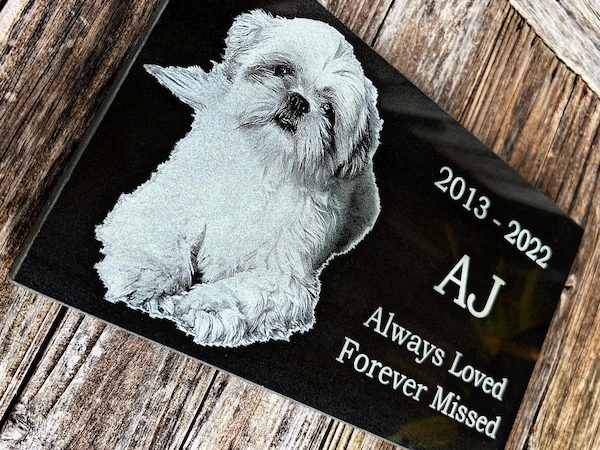

The art of laser engraving on stone has become increasingly popular, offering endless creative possibilities. As more people discover the charm of laser engraved stone products, they’re finding unique ways to bring artistry into their daily lives.

Take a look at these inspiring laser engraved stone creations shared by our Facebook community:

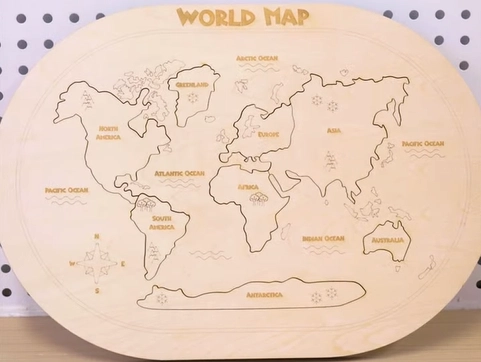

Stone engraved maps

Memorial stone engraving

Photo engraving

Slate coasters

3D engraving

Cartoon pattern engraving

©Bella Wang

What is the best stone for laser engraving?

Granite is generally considered the best stone for laser engraving due to its consistent density, durability, and the high contrast it produces when engraved. Black granite particularly stands out as it creates the sharpest contrast, showing white or light gray markings against the dark background, resulting in crisp, clear, and highly visible engravings.

Other good options include marble, slate and pebbles, but granite’s uniform composition and ability to withstand the laser process while producing excellent detail makes it the top choice for professional laser engraving projects.

How to select the right stone for laser engraving on stone?

1. Surface texture

2. Color and contrast

3. Size and shape

How to engrave rocks and stones with lasers?

1. Material preparation

2. Surface leveling

3. Settings management

4. Color considerations

5. Ventilation requirements

What settings should a laser engrave rocks?

The results of laser engraving on stone are influenced by many factors, with material being the primary consideration. We have provided reference processing parameters based on our Thunder Laser Bolt and Thunder Aurora machines, using marble and slate as examples.

| Laser source | Material | Marking result | Speed(mm/s) | Power(%) | Blow Type | Frequency(khz) | Bi-directional or not | DPI |

|---|---|---|---|---|---|---|---|---|

| 30w (RF) | Marble | / | 1000 | 40 | low | / | / | 350 |

| 50w (fiber) | Slate | White | 200 | 20 | / | 60 | Double | / |

Choose the laser for your laser engraving stone project

The key to creating excellent laser-etched stone pieces is having a quality stone engraver. Thunder Laser Machines offer both high quality and high precision, making laser engraving stone an effortless process. Our different series of machines have distinct features that benefit stone etching.

First, our flagship CO2 Nova Series stands out with its higher laser power and a working platform with pass-through doors, making it ideal for those who need precise and high-volume cutting. You can effortlessly process larger stone materials with these machines.

Second, the Bolt Series, also using CO2 lasers, performs custom stone engraving with its desktop-sized format, perfect for enthusiasts. For those seeking higher precision and professional results, the Bolt Pro offers enterprise-level accuracy for laser-etched stone works.

Additionally, the Aurora series, equipped with Fiber Lasers or UV lasers, can etch into stone with high energy, creating deep markings. While primarily designed for metal marking in a desktop format, it’s also commonly used for processing laser engraved stone works like slate.

You can select the machine based on your specific needs! We’re always here to provide professional consultation and service to answer your questions.

What techniques are used in rock engraving?

How to engrave clear photos on stone?

Image preparation is critical for successful photo engraving on stone. Start with high-contrast images but use a lower resolution of 250-333 DPI, as stones’ natural texture makes ultra-fine details difficult to reproduce. You can adjust your image settings by increasing contrast slightly and converting to grayscale, ensuring dark areas will engrave deeply enough while maintaining lighter details. Additionally, consider the stone’s natural texture and color – darker stones often produce clearer photo engravings with better contrast.

How to increase contrast in laser engraved stone?

After engraving and cleaning off debris, apply a stone enhancer or sealer to enhance contrast and protect your work. You can simply apply a thin, even layer using a clean, soft cloth or brush. Work in small sections to ensure complete coverage, and wipe off any excess after a few minutes to prevent residue buildup. For outdoor pieces, consider using a UV-resistant sealer like StoneTech Professional BulletProof Sealer.

Most enhancers require 24-48 hours to fully cure – during this time, keep the stone in a clean, dry environment away from direct sunlight and moisture.

How to store laser engraved stone?

- Tags

.png) International

International

United States

United States

Brasil

Brasil

Canada

Canada

Costa Rica

Costa Rica

Česká

Česká

Ελλάδα

Ελλάδα

Polska

Polska

Ireland

Ireland

Portugal

Portugal

Lietuva

Lietuva

Россия

Россия Deutschland

Deutschland

Britain

Britain

Україна

Україна

France

France

Sverige

Sverige

Italia

Italia

Norway

Norway

Denmark

Denmark

Romania

Romania

한국

한국

中国

中国

ประเทศไทย

ประเทศไทย

中国香港

中国香港

Israel

Israel

中國臺灣

中國臺灣

India

India

پاکستان

پاکستان

پශ්රී ලංකා

پශ්රී ලංකා

Australia

Australia

New Zealand

New Zealand

South Africa

South Africa