Efficient Laser Engraving Ceramic Tile

- Home

- >

- Laser engraver materials

- >

- Efficient Laser Engraving Ceramic Tile

Outline

Can you laser engrave ceramic?

Ceramic is a highly durable and versatile material, known for its hardness, non-porous surface, and resistance to heat and chemicals. These properties make ceramic tiles ideal for both practical and decorative purposes, commonly used in flooring, wall coverings, and home decor.

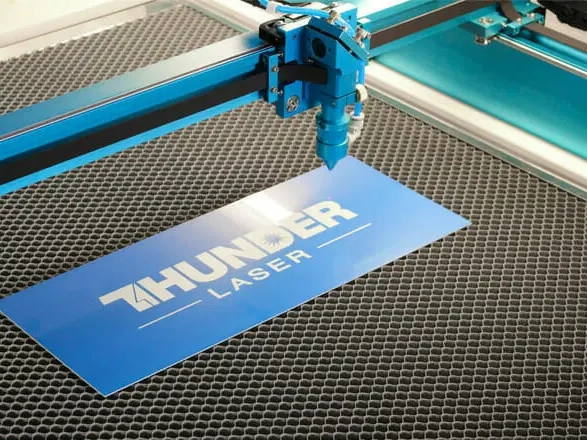

Among all ceramic engraving tools, lasers are the most efficient for engraving ceramic tiles. When it comes to laser engraving, ceramic’s smooth surface and ability to withstand high temperatures make it an excellent choice. The laser interacts with the surface to either remove a thin layer or create a color contrast, resulting in detailed and long-lasting designs.

Laser engraving ceramic tiles involves using a precise laser beam to etch patterns, text, or images onto the surface. The process is non-contact and highly customizable, allowing for intricate designs without compromising the tile’s durability. It’s a popular choice for creating personalized gifts, decorative art, or unique signage.

Two methods for laser engraving ceramic tiles

Removing the glaze layer

Color contrast creation

Can you laser cut ceramic tiles?

Laser cutting ceramic is not as straightforward as laser engraving. Ceramic’s hardness and heat resistance make it challenging for standard laser machines to cut through effectively. Unlike materials like wood or acrylic, ceramics do not vaporize or burn away under a laser beam. Instead, the intense heat can cause cracking, chipping, or uneven edges.

High-powered industrial lasers, such as fiber lasers with specialized setups, can sometimes cut certain types of ceramic. However, the process is often slow and requires careful calibration to avoid damage. Additionally, many ceramics, especially glazed ones, are not suited for cutting due to their fragile nature under thermal stress.

In a word, laser cannot cut ceramic tile effectively. If cutting is necessary, water jet cutting or mechanical tools are typically more effective and reliable for ceramics.

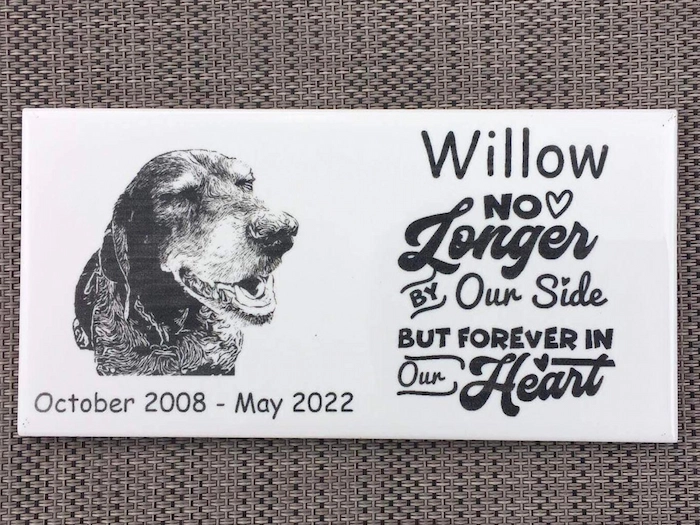

Creative laser engraving ceramic ideas

- Photo engraving

©Jeremiah Wagner

- Custom ceramic mugs

- Memorial plaques

Visit our sample library for more project ideas! We regularly update it with creative applications across various materials to inspire your next masterpiece.

What type of laser can engrave ceramics?

Engraving ceramics requires a laser capable of handling hard, brittle surfaces effectively. Two primary laser types are suitable for this task: CO2 lasers and fiber lasers, each offering distinct advantages depending on the material and design requirements.

CO2 lasers are the most commonly used for engraving ceramics due to their versatility and precision. They excel at creating detailed, high-contrast designs on uncoated ceramic surfaces, such as tiles and mugs. The laser’s heat interacts with the ceramic material, producing a frosted or etched effect. These lasers are particularly effective for photo engraving and intricate patterns.

Fiber lasers are less commonly used for ceramics but can be effective for coated or treated ceramic surfaces. For instance, if the ceramic has a painted or glazed layer, fiber lasers can ablate the coating to reveal the base material, creating crisp and precise engravings. However, they are not ideal for bare ceramics as they are less efficient at altering the raw surface.

In summary, CO2 lasers are the best choice for engraving uncoated ceramics, while fiber lasers are more suitable for coated ceramic surfaces.

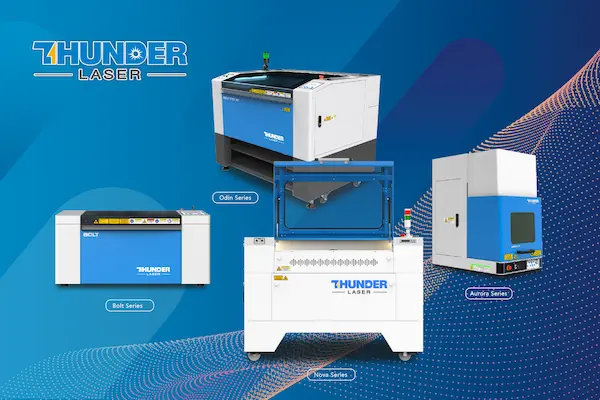

Choose a suitable ceramic engraving machine for you!

A high-performance CNC ceramic engraving machine can help you process ceramics more effectively! You can choose between a CO2 laser or a fiber laser based on your specific needs, and Thunder Laser is here to provide the perfect solution.

If your primary focus is processing non-metal materials, a CO2 laser is an excellent choice. Thunder Laser Nova is a powerful laser cutter capable of efficient laser engraving on ceramic. It features a large working area, making it ideal for quick batch production. For precision ceramic tile engraving, Thunder Laser Bolt series offers unmatched accuracy. You can opt for the compact, hobby-friendly Thunder Bolt desktop machine or the more professional, enterprise-grade Bolt Pro for workshop use.

On the other hand, if your engraving needs are more focused on metals, consider the Thunder Aurora series. Equipped with either a fiber laser or UV laser source, it can deliver permanent laser marking. Its compact size allows you to complete projects conveniently at home while also excelling in producing flawless laser-engraved ceramic tile products.

Choose the machine that best suits your requirements! We’re always here to assist you.

What laser settings for ceramic engraving?

Accurate and effective engraving requires the right settings. Here, we provide laser engraving ceramic tile settings using the Thunder Bolt – 30W (RF tube). However, it’s important to test and adjust these settings based on your specific machine and desired results before starting the actual process.

| Thickness | Process | Speed(mm/s) | Min Power(%) | Max Power(%) | Blow Type | DPI |

|---|---|---|---|---|---|---|

| / | Engraving | 1000 | 60 | 60 | low | 350 |

Find more comprehensive material parameter tables in our knowledge base!

Tips and tricks for ceramic laser engraving

1. How to prepare ceramic tiles for engraving?

Clean the surface: Use alcohol to clean the ceramic tile surface and allow it to dry completely. It’s recommended to wear gloves when handling the tile to avoid leaving oil or grease marks.

Secure the ceramic tile: To prevent movement during engraving, the ceramic tile should be firmly secured in place. Use clamps or other suitable fixtures to hold it securely.

2. How to stay safe when laser engraving ceramic?

Ceramic is a hard, brittle material that can crack or sustain damage from heat shock during engraving. To ensure safety, follow these precautions:

Calibrate laser parameters: Adjust the laser power, speed, and focus to appropriate settings to avoid unnecessary cracks or surface burns.

Ensure proper ventilation: Ceramic engraving produces fine dust that can linger in the air. Ensure the workspace is well-ventilated to minimize inhalation risks.

Use a safety cover: Install a protective cover on the laser machine to shield against debris that might be ejected when removing the glaze layer.

3. How to store ceramic tiles?

- Tags

#ceramic, #ceramic tile, #laser, #laser engraving, #ceramic engraving, #laser engraving ceramic, #ceramic engraving machine, #laser engraving ceramic tile settings, #co2 laser, #fiber laser, #laser machine, #laser engraver

.png) International

International

United States

United States

Brasil

Brasil

Canada

Canada

Costa Rica

Costa Rica

Česká

Česká

Ελλάδα

Ελλάδα

Polska

Polska

Ireland

Ireland

Portugal

Portugal

Lietuva

Lietuva

Россия

Россия Deutschland

Deutschland

Britain

Britain

Україна

Україна

France

France

Sverige

Sverige

Italia

Italia

Norway

Norway

Denmark

Denmark

Romania

Romania

한국

한국

中国

中国

ประเทศไทย

ประเทศไทย

中国香港

中国香港

Israel

Israel

中國臺灣

中國臺灣

India

India

پاکستان

پاکستان

پශ්රී ලංකා

پශ්රී ලංකා

ジャパン

ジャパン

Australia

Australia

New Zealand

New Zealand

South Africa

South Africa