- Author: Shirley

Do you know that laser sources are evolving at an amazing rate? Their innovations are transforming industries across the globe. The future of laser sources promises greater efficiency, accessibility and flexibility. Get ready to discover MORE!

Fast Pass to Knowledge

What Do the Latest Reports Say About Laser Sources?

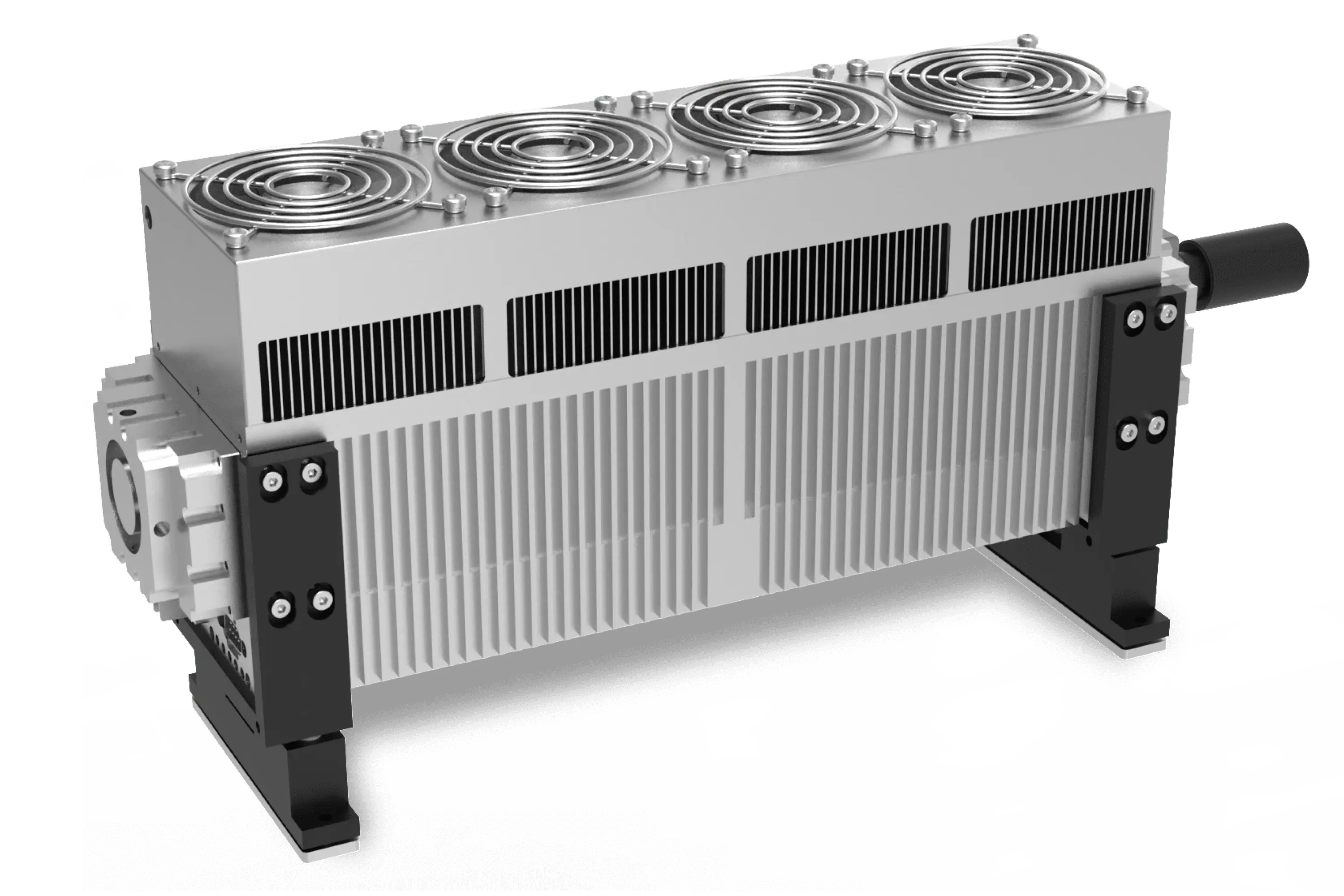

Fiber lasers

The compound annual growth rate (CAGR) for the fiber laser market is expected to over 10% in 2025. Renowned for efficiency and ultra precision in metal processing, fiber lasers are increasingly favored in high-demand sectors.

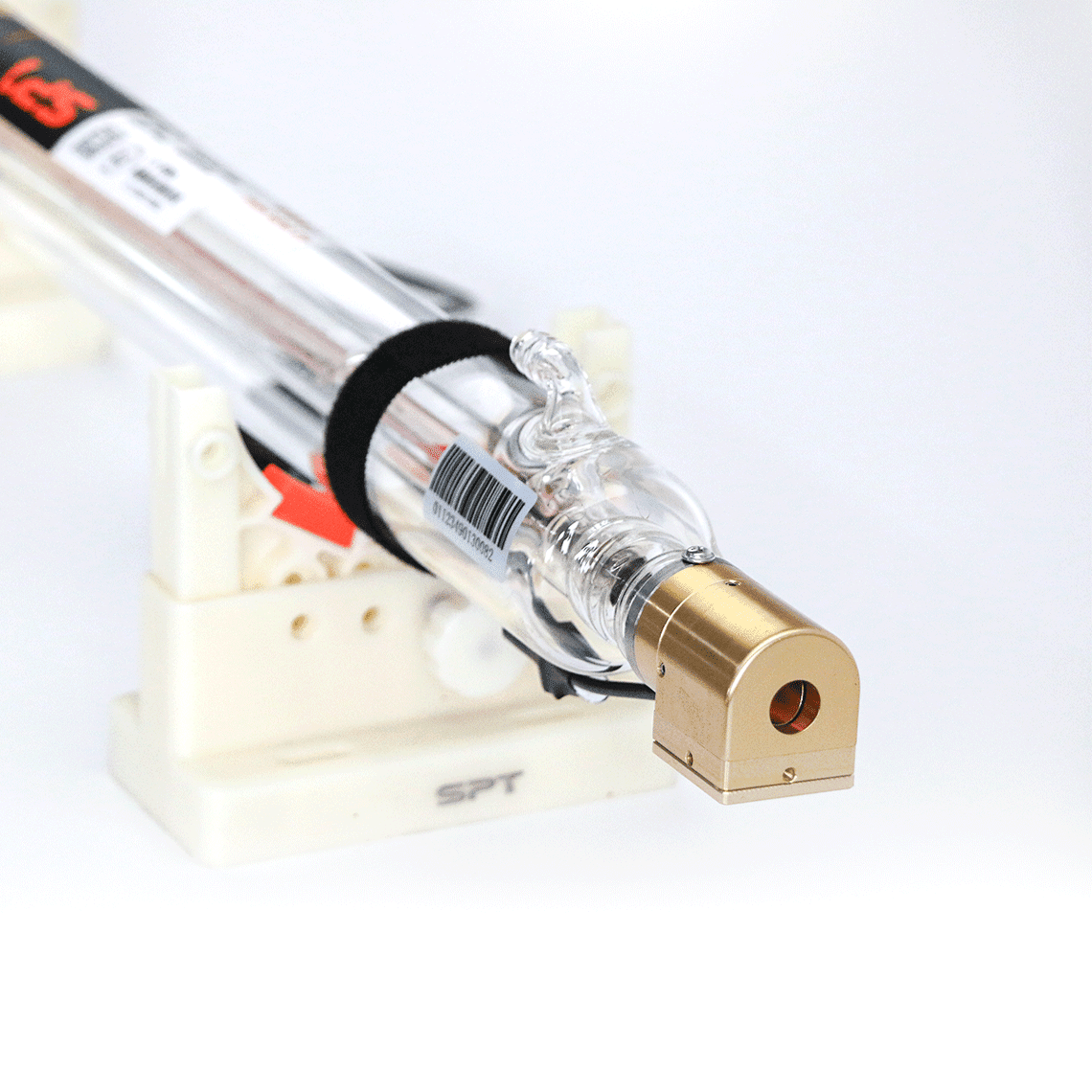

CO₂ lasers

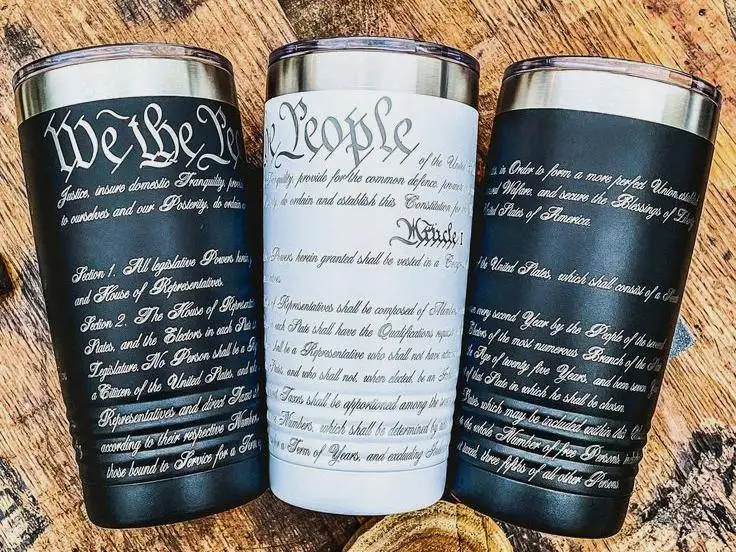

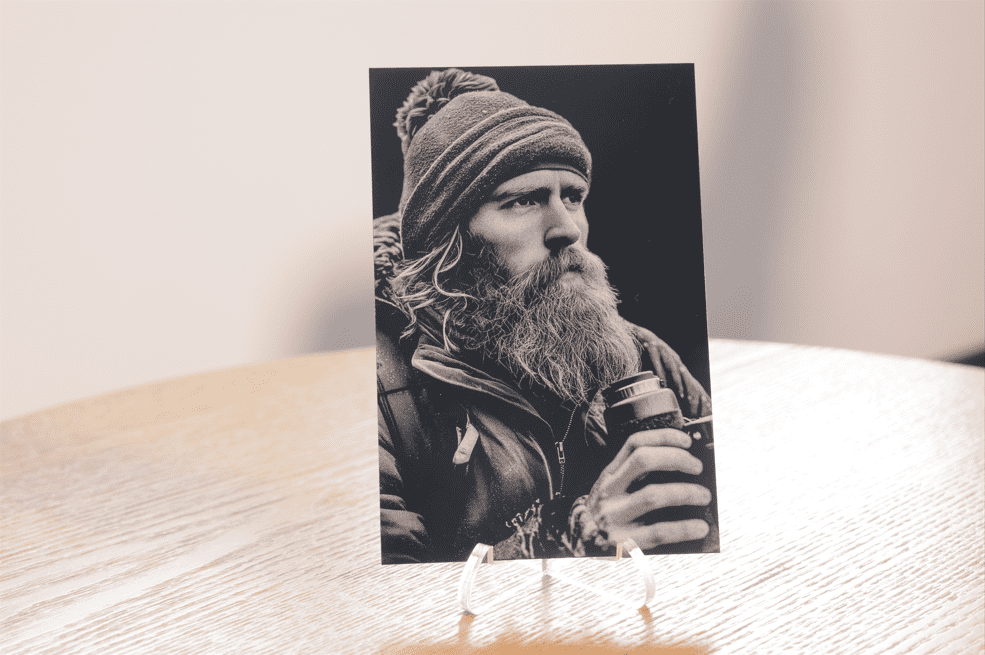

CO₂ lasers maintain their stronghold in engraving and cutting a wide range of non-metal materials, fueling growth in creative industries and bespoke manufacturing.

Diode lasers

Diode lasers are moving toward higher power, which expands their applications. However, their usage remains limited by challenges in transparent and composite materials processing.

What are the Main Trends in Laser Sources Today?

Performance

High-performance laser sources allow for more consistent and accurate cutting, engraving, and marking on a variety of materials. Better performance means more efficient operation as well as higher quality and consistent finished products. That’s why high-quality and high-volume production businesses tend to use high-performance laser sources.

Cost Reductions

- Laser sources become more affordable. The growing need for cost-effective solutions has led to advancements in material science and manufacturing processes, making high-quality laser sources available at lower prices. This shift is allowing more businesses, from small startups to large enterprises, to incorporate lasersinto their operations, expanding their applications.

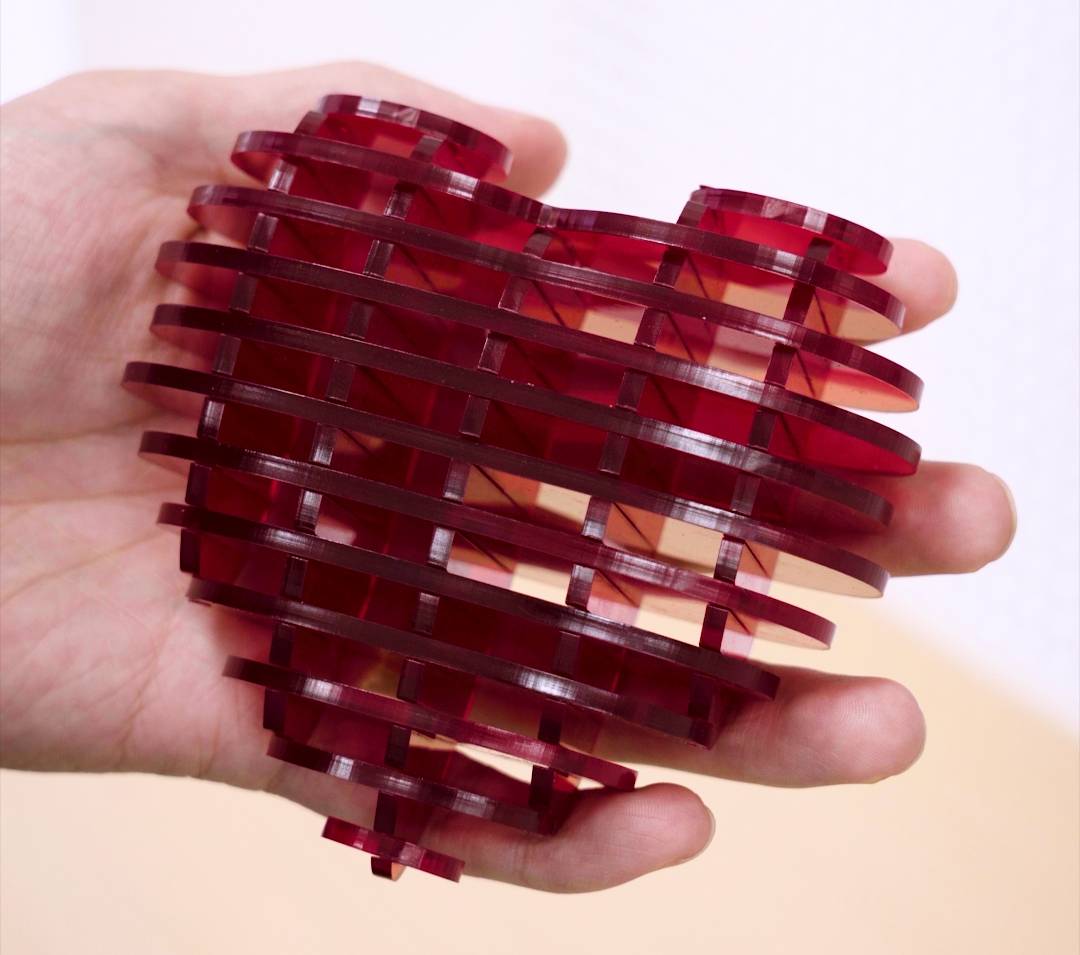

Versatility

- Businesses are increasingly seeking multifunctional solutions, which has prompted the evolution of laser sources that can handle a variety of tasks, from cutting and engraving to marking, all in one system. This flexibility is reshaping how laser sources are used across industries, pushing the design of modular systems that can easily be adjusted to accommodate different materials and tasks. As the demand for versatile solutions grows, laser sources are adapting to meet these evolving needs.

What Innovations are Fueled by the Trends?

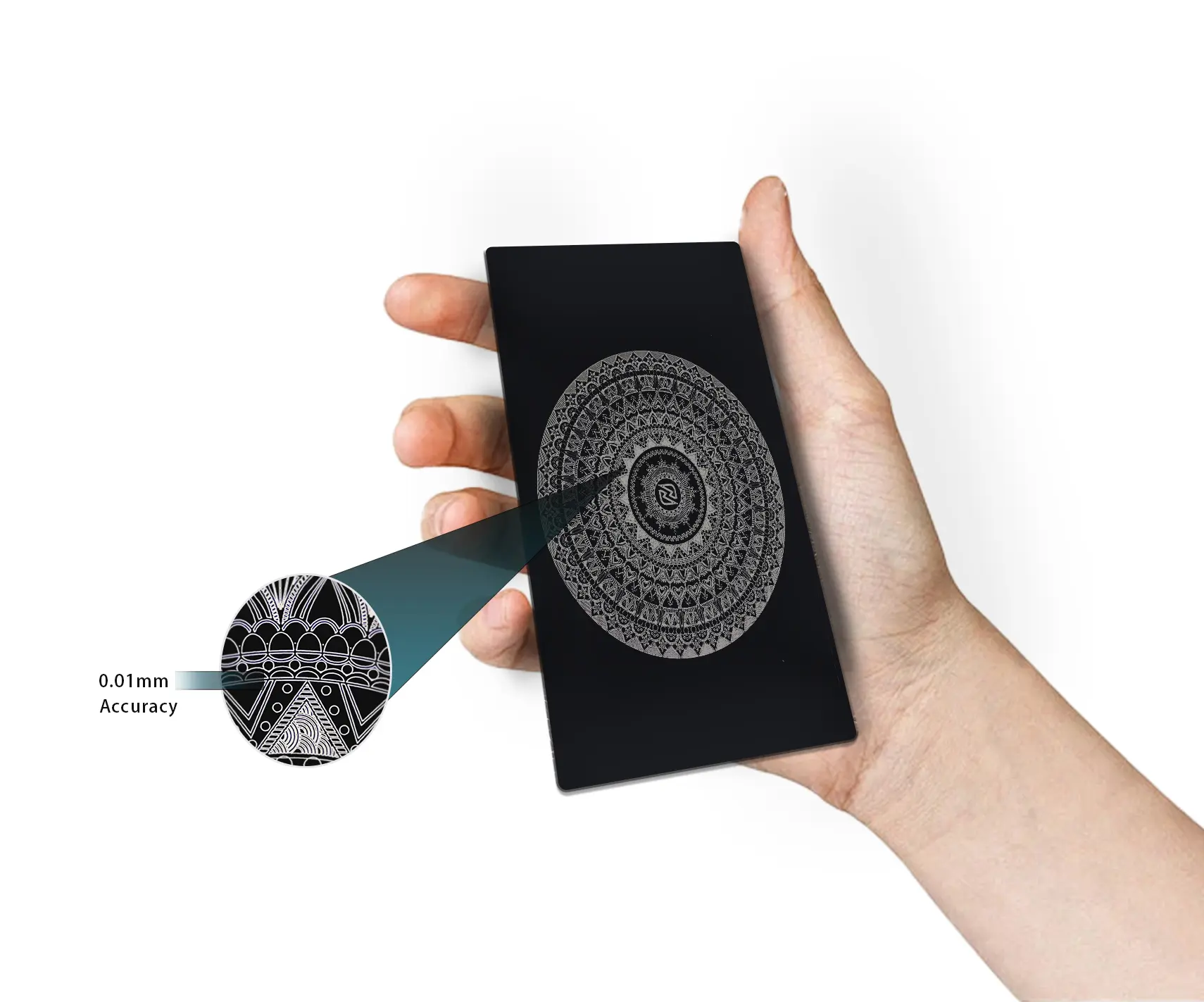

Precision

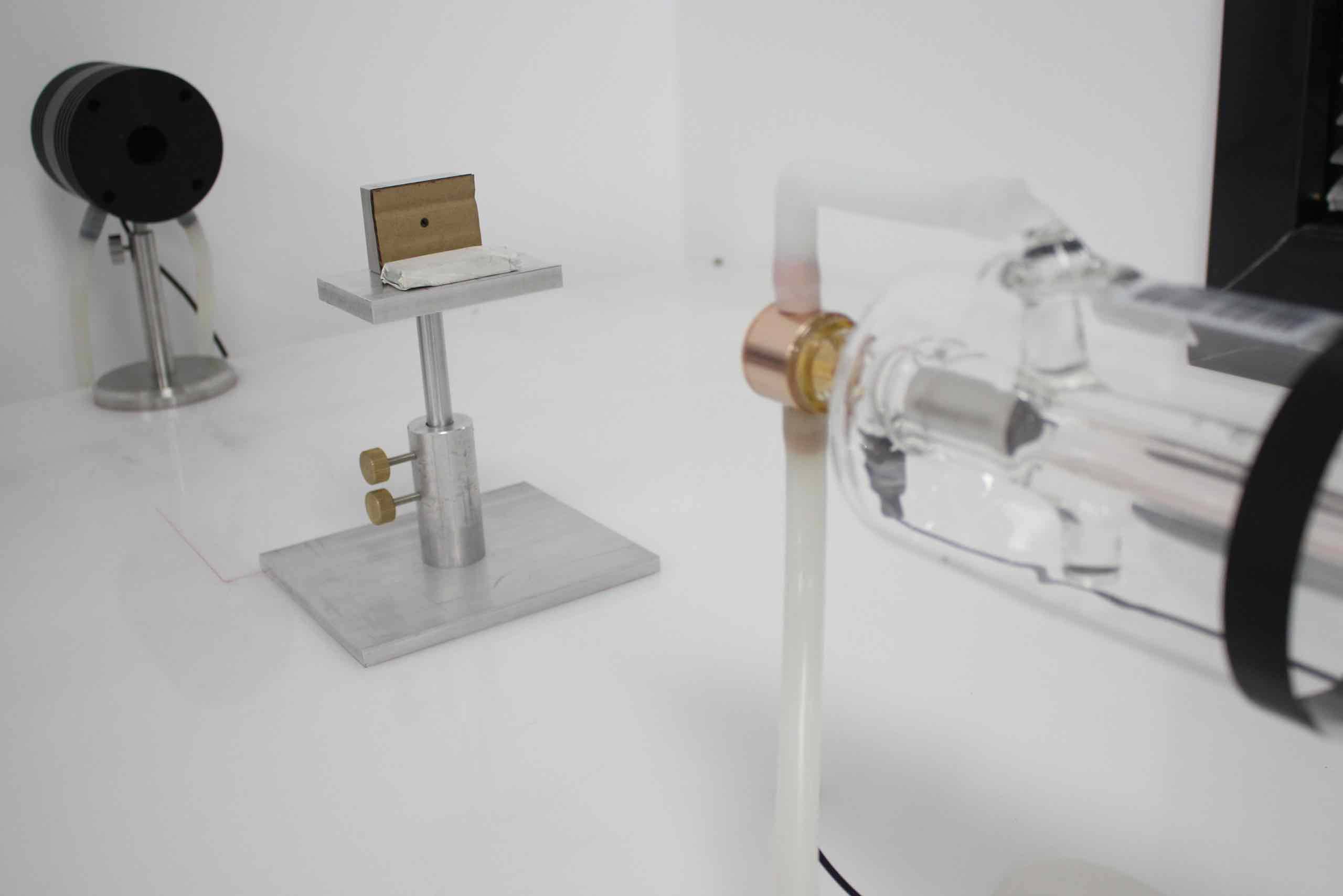

An important advancement is the radio frequency (RF) laser source, which offers superior performance for finer engraving and cutting with exceptional accuracy.

Miniaturization

Compact desktop laser engravers are gaining popularity for saving space and reducing costs, largely due to the miniaturization of laser sources, making high-performance laser far more accessible to small studios and home workshops.

Multi-Laser Source Integration

Combination of laser sources allows a single machine to handle metal and non-metal cutting, engraving and marking. The integration of various laser sources, such as RF tubes and fiber lasers, expands the laser engraver’s applications like never before and provides users with superior convenience.

How to Tap into the Opportunities in Laser Source Innovation?

Focus on Performance and Precision

- As lasers become more precise, businesses can offer higher-quality products with less waste. By incorporating high-performance laser sources into your operations, you can ensure better consistency and quality in your work, particularly when dealing with intricate designs or high-volume orders. This not only boosts customer satisfaction but can also improve operational efficiency.

Take Advantage of Cost-Effective Solutions

- Laser sources are becoming more affordable thanks to advancements in materials and manufacturing techniques. For small businesses or startups, this means high-quality laser systems are now within reach, enabling them to explore new markets and expand their capabilities. By choosing cost-effective solutions, you can lower your upfront investment and reduce operating costs, allowing for faster scalability.

Learn More About Laser Sources

Understanding the various types of laser sources is essential for businesses seeking to optimize their operations. By diving deeper into the characteristics and capabilities of these laser sources, businesses can make informed decisions on the best machinefor their needs. Moreover, staying updated on emerging technologies and innovations will keep your business ahead of the curve, enabling you to leverage the latest tools for greater productivity and efficiency.

What should I know about the challenges posed by innovations in laser sources?

Initial Costs

Although the overall cost of laser sources is decreasing, the upfront investment for cutting-edge technologies may still be high. Businesses looking to adopt the latest innovations might face financial barriers, especially small startups or those with limited budgets. It’s essential to weigh the long-term benefits of these innovations against their initial costs and carefully assess whether they align with the company’s growth strategy.

Technology Obsolescence

As laser sources evolve rapidly, businesses must stay updated to avoid the risk of obsolescence. Newer solutions may render older equipment less efficient or incompatible with emerging materials. Consideration needs to be given to how often the laser system should be upgraded to keep up with business developments while avoiding unnecessary costs.

Skilled Labor Shortage

- With the advancement of laser sources, there is a growing demand for skilled technicians capable of operating and maintaining these new The shortage of experienced professionals can create challenges for businesses in terms of training, recruitment, and overall productivity.

Conclusion

The future of laser sources maintains a very optimistic growth rate, and rapid innovation will open up new possibilities for a wide range of industries around the world. As laser sources continue to evolve, organizations can expect greater efficiency, precision and flexibility from new technologies.

Constantly innovating laser sources are creating the conditions for smarter, more versatile solutions for applications ranging from precision manufacturing to creative design. However, these advances also present challenges. Therefore, capitalizing on the opportunities presented by laser source innovation requires being informed, investing in cost-effective lasers, and adapting to the changing technology landscape.

.png) International

International

United States

United States

Brasil

Brasil

Canada

Canada

Costa Rica

Costa Rica

Česká

Česká

Ελλάδα

Ελλάδα

Polska

Polska

Ireland

Ireland

Portugal

Portugal

Lietuva

Lietuva

Россия

Россия Deutschland

Deutschland

Britain

Britain

Україна

Україна

France

France

Sverige

Sverige

Italia

Italia

Norway

Norway

Denmark

Denmark

Romania

Romania

한국

한국

中国

中国

ประเทศไทย

ประเทศไทย

中国香港

中国香港

Israel

Israel

中國臺灣

中國臺灣

India

India

پاکستان

پاکستان

پශ්රී ලංකා

پශ්රී ලංකා

ジャパン

ジャパン

Australia

Australia

New Zealand

New Zealand

South Africa

South Africa