- Author: Virgil

Technology in laser engraving machines has become integral in many industrial, commercial, and creative applications. Two predominant types of lasers—RF lasers and DC Glass Lasers—are commonly utilized, each with its unique capabilities and advantages.

Understanding the distinct characteristics of these lasers is essential when selecting the best technology for your specific project needs. Whether you are dealing with precision engraving, cutting, or marking, knowing the differences can make all the difference in performance, efficiency, and cost-effectiveness.

1. What is RF Laser?

RF lasers are powered by energy emitted through antennas, with the excitation frequency typically falling within the radio frequency range of 86 MHz to 48 MHz. This radio frequency excites nitrogen molecules, inducing vibrational energy within the system.

RF lasers are capable of operating at significantly higher repetition rates compared to DC Glass Lasers, allowing for rapid engraving and marking. In this context, each contrasting pixel is generated by a single laser pulse. When the laser resonator is constructed using aluminum oxide ceramic, it offers the advantage of minimal impedance at the excitation frequency. This characteristic allows for efficient pumping with minimal loss.

Additionally, since the antennas are positioned externally to the resonator, there are no feed-throughs that could compromise the gas impermeability of the system.

How Does RF Lasers Work?

The core mechanism of an RF laser revolves around radio frequency energy. When RF power is introduced to the laser tube, it excites the CO2 gas or other gases within the tube. This excitation generates high-energy photons that are then emitted as a coherent laser beam. This process is more energy-efficient and results in a high-quality beam with minimal fluctuations in power, ensuring consistent performance.

2. What is DC Glass Laser?

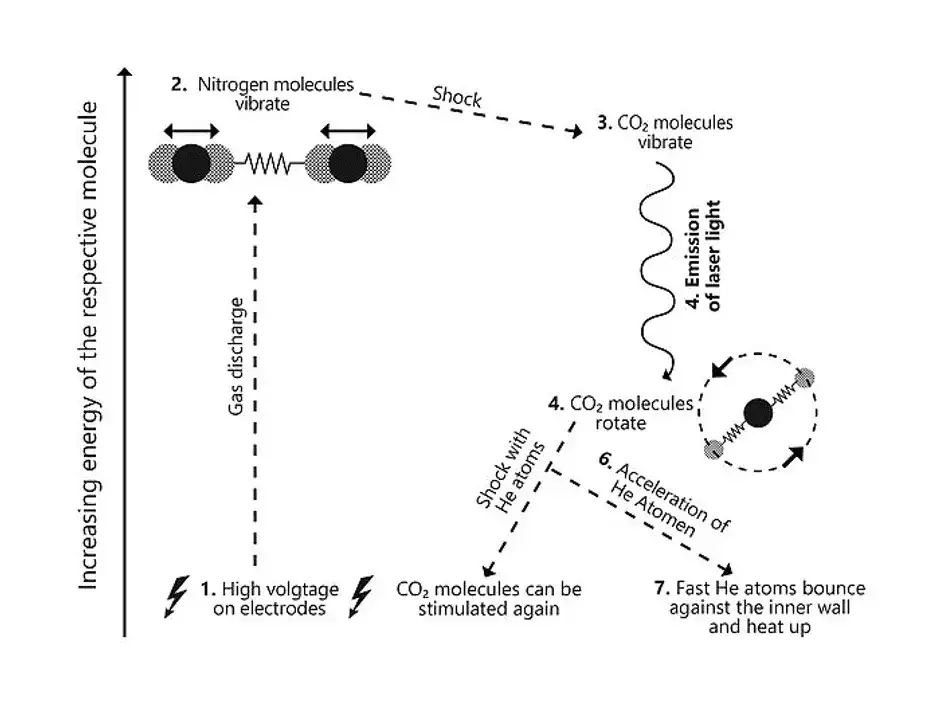

DC Glass Laser sources are typically housed within a glass laser tube, which contains a mixture of gases, including nitrogen (the predominant component), carbon dioxide (serving as the laser-active medium), helium (for efficient heat dissipation), and often hydrogen or xenon.

A high voltage applied to the electrodes within the tube initiates the flow of current. These electrodes are designed as feedthroughs that penetrate the glass body, introducing potential weak points in the system.

Due to thermal expansion discrepancies between the metal electrodes and the glass tube, maintaining the impermeability of the laser tube becomes challenging, especially under temperature fluctuations. As temperatures increase, the differing expansion rates of the glass and metal exert pressure on the seals, potentially leading to leakage over time, particularly after numerous thermal cycles.

How Does DC Glass Lasers Work

In DC Glass Lasers, direct current is passed through a laser tube, exciting the CO2 gas or other gas mixtures inside. This excitation creates photons that are emitted as a laser beam. The simple direct current excitation provides a more basic approach to laser generation than the radio frequency excitation used in RF lasers.

3. RF Laser vs DC Glass Laser: Performance Comparison

Selecting between RF lasers and DC glass lasers requires an in-depth understanding of their performance characteristics. Each technology has its strengths and is suited for different applications, from precision engraving to large-scale cutting.

Here we provide a comprehensive comparison of several dimensions of comparison to help determine the best choice for specific needs.

3.1. Power Output and Consistency

RF Lasers

RF lasers offer exceptional power consistency, delivering a more stable and uniform output over time. This consistency is crucial for high-precision applications where uniformity is necessary across the entire engraving or cutting process. The precise control of power output enables RF lasers to achieve consistent results, even on materials that require intricate detailing or high-contrast work. This level of control is particularly beneficial in industries that demand high-quality, reliable performance.

DC Glass Lasers

While DC Glass Lasers provide stable power output, they may experience slight variations over time due to the nature of their power source. These fluctuations can result in minor inconsistencies in engraving or cutting, particularly on more demanding materials.

However, for general applications, DC Glass Lasers offer a reliable and steady performance, making them ideal for projects that don’t require the extreme consistency of RF lasers.

Typically, if you want to convert the performance of RF laser power to DC glass power, 1.5-2.0 times is the answer. For example, a 60 Watts RF laser power equals 80-120 Watts DC glass power.

3.2. Material Compatibility

RF Lasers

RF lasers are perfect for materials that demand precision and durability, such as metal (stainless steel, aluminum), glass, and ceramics. They can handle a wide range of materials with exceptional results, particularly when high-contrast engraving is required.

DC Glass Lasers

DC Glass Lasers excel in non-metallic materials like wood, acrylic, leather, and paper. They are often used in industries like crafting, signage, and fashion, where precision is necessary but not to the level required by RF lasers.

3.3. Accuracy in Engraving and Cutting

RF Lasers

RF lasers offer exceptional accuracy, achieving submicron-level precision. This makes them perfect for applications requiring fine, intricate engravings or cuts.

DC Glass Lasers

DC Glass Lasers are slightly less accurate, but they still provide high-quality results for applications like wood engraving and acrylic cutting.

3.4. Power and Speed Control

RF Lasers

RF lasers offer dynamic power control, allowing for variable speed and depth adjustments to achieve highly detailed results on complex materials.

DC Glass Lasers

While DC Glass Lasers offer sufficient power and speed control, their adjustments tend to be less precise, which may lead to slightly less fine-tuned performance.

3.5. Lifespan and Maintenance

RF Lasers

RF lasers generally have a longer lifespan and require less maintenance due to their robust construction. Their design leads to fewer parts that wear out, resulting in less frequent service and minimal downtime.

DC Glass Lasers

DC Glass Lasers, while efficient and cost-effective, often require more frequent maintenance. Their simpler design means that they may be prone to wear over time, especially under heavy use.

3.6. Cost Considerations

RF Lasers

RF lasers may cost a higher price in the similar performance comparing to DC Glass Lasers, but they tend to have lower ongoing costs because they require less maintenance and operate more efficiently.

DC Glass Lasers

DC Glass Lasers are generally more affordable upfront, making them a better choice for businesses with limited budgets. However, on the other hand, DC Glass Lasers require more frequent servicing, which can lead to higher operational costs in the long run.

3.7. Summary Table

| Feature | RF Lasers | DC Glass Lasers |

|---|---|---|

| Power Output and Consistency | Stable and uniform output for high-precision work. | Slight fluctuations, but still reliable for general applications. |

| Material Compatibility | Ideal for metals, glass, ceramics, and high-contrast engraving. | Best for non-metallic materials like wood, acrylic, and leather. |

| Accuracy in Engraving and Cutting | Submicron-level precision for intricate details. | High-quality results, but slightly less precise. |

| Power and Speed Control | Dynamic control with variable speed and depth. | Adequate power and speed control, but less precise adjustments. |

| Lifespan and Maintenance | Longer lifespan with minimal maintenance needs. | Requires more frequent maintenance due to wear over time. |

| Cost Considerations | Higher initial cost but lower ongoing maintenance. | More affordable upfront, but higher maintenance costs in the long run. |

Although the price cost of RF lasers is still higher than DC glass lasers, due to the growth of the laser industry in China, the threshold of RF lasers has declined. It’s the new era to get a higher-precision and faster-speed laser engraving.

4. Explore Thunder Nova—Best DC Glass Laser Engraver to Best RF Laser Engraver

Choosing the right laser engraver depends on the balance between affordability, precision, and long-term performance. The Thunder Nova series and Thunder Nova Plus series offer two distinct solutions—one optimized for cost-effective, high-quality engraving with DC glass tubes, and the other designed for superior precision and durability with RF laser technology. Understanding their differences ensures you select the best engraver for your specific applications.

The Thunder Nova series is designed for those seeking high-performance DC glass tube laser engravers, offering reliability and versatility across a wide range of materials. Whether working with wood, acrylic, leather, or other non-metallic surfaces, the Nova series delivers consistent results, making it a trusted choice for industries like signage, crafts, and manufacturing.

For those requiring higher precision, speed, and durability, the Thunder Nova Plus series features a high-end RF laser tube by Iradion, offering superior engraving quality and efficiency. With enhanced power control and improved beam consistency, Nova Plus excels in intricate engraving applications on metals, glass, and other high-contrast materials. This advancement makes the Nova Plus series the optimal solution for professionals seeking greater precision, longevity, and performance in laser processing.

Conclusion

When choosing between RF and DC glass lasers, understanding their strengths is key. RF lasers offer superior precision, faster engraving, and a longer lifespan, making them ideal for industries like aerospace, electronics, and medical manufacturing. Their consistent power and fine beam control ensure high-quality results with minimal maintenance.

DC glass lasers, while more affordable, still provide excellent engraving on materials like wood, acrylic, and leather, making them popular in signage, crafting, and general manufacturing. Though they require more maintenance and lack RF lasers’ ultra-fine precision, they remain a cost-effective option.

For longevity, precision, and efficiency, RF lasers are the best investment. However, for budget-conscious businesses, DC glass lasers offer reliable performance at a lower cost.

.png) International

International

United States

United States

Brasil

Brasil

Canada

Canada

Costa Rica

Costa Rica

Česká

Česká

Ελλάδα

Ελλάδα

Polska

Polska

Ireland

Ireland

Portugal

Portugal

Lietuva

Lietuva

Россия

Россия Deutschland

Deutschland

Britain

Britain

Україна

Україна

France

France

Sverige

Sverige

Italia

Italia

Norway

Norway

Denmark

Denmark

Romania

Romania

한국

한국

中国

中国

ประเทศไทย

ประเทศไทย

中国香港

中国香港

Israel

Israel

中國臺灣

中國臺灣

India

India

پاکستان

پاکستان

پශ්රී ලංකා

پශ්රී ලංකා

ジャパン

ジャパン

Australia

Australia

New Zealand

New Zealand

South Africa

South Africa