- Author: Cathy

1. Can acrylic be laser cut?

Of course yes. Laser cutting has become the preferred method for many professionals and hobbyists working with acrylic, offering a combination of quality, speed, and versatility that’s hard to match with other cutting methods.

The thickness of acrylic sheets for laser cutting that can be cut depends on the laser’s power. Most standard CO2 lasers used in small to medium-sized operations can effectively cut laserable acrylic sheets up to 1/2 inch (12mm) thick, while more powerful industrial lasers can handle even thicker materials.

Is plexiglass the same as acrylic?

Yes, plexiglass and acrylic are essentially the same material. “Plexiglass” is a trade name that has become synonymous with acrylic sheets. The material itself is called polymethyl methacrylate (PMMA), and it is sold under various brand names, including Plexiglas, Acrylite, Lucite, and Perspex. They are lightweight, durable, and highly transparent, making them popular for various applications such as windows, signs, and protective barriers.

2. What kind of acrylic is used for laser cutting?

By manufacturing methods

Cast Acrylic

Extruded Acrylic

Extruded acrylic is not as ideal for laser cutting as cast acrylic. While it can be cut with a laser, the edges tend to be rougher. Additionally, extruded acrylic is more prone to melting during the cutting process, leading to uneven cuts and requiring more post-processing. But being less expensive, it’s generally better suited for applications where the edge quality is less critical or where other methods of cutting are being used.

By finishes and appearances

Clear Acrylic

The most common type, available in both cast and extruded forms. It’s widely used for general applications like decorations, advertising boards and so on.

Colored Acrylic

Mirrored Acrylic

Textured Acrylic

Features patterns or textures on one or both sides. This type is often used in decorative panels, personal accessories and so on.

In addition to these commonly used types, there are also matte Frosted Acrylic and light-reactive Fluorescent Acrylic. Each of these types can be used with a laser cutter, but the specific choice depends on the visual and functional needs of your project.

3.What is the best acrylic for laser cutting?

- Optical clarity

- Consistent thickness

- Low internal stress

- Minimal warping when heated

- Clean cutting edges

Based on these criteria, extruded acrylic sheets are generally considered the best option for laser cutting. Here’s why:

- Cast acrylic has better optical clarity compared to extruded acrylic.

- It cuts more cleanly, leaving smoother edges that require less post-processing.

- It tends to warp less when heated by the laser.

- Cast acrylic has lower internal stress, which reduces the risk of cracking during cutting.

The thickness of the acrylic sheet also matters. Thinner sheets (1/8″ to 1/4″) are easier to cut and produce cleaner edges. For thicker materials, you may need multiple passes or higher laser power.

Additionally, it’s important to consider the specific requirements of your project, such as color, finish (glossy or matte), and any special properties like UV resistance.

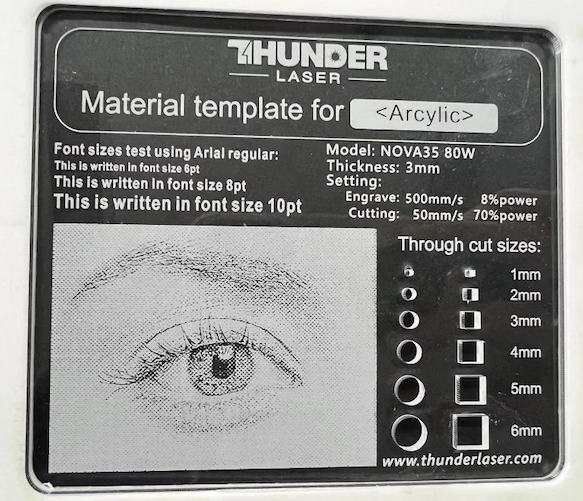

What are the best settings to laser cut acrylic?

Power and speed

Air Assist

Passes

4. Where to buy acrylic sheets for laser cutting?

Online retailers

Plastics suppliers

Local hardware stores

Direct from manufacturers

Consider factors like shipping costs, minimum order quantities, and return policies when choosing a supplier. Local pickup can sometimes be more economical for larger sheets. Also, check if the retailer offers custom cutting services if you need specific sizes of laser acrylic sheets.

- Tags

.png) International

International

United States

United States

Brasil

Brasil

Canada

Canada

Costa Rica

Costa Rica

Česká

Česká

Ελλάδα

Ελλάδα

Polska

Polska

Ireland

Ireland

Portugal

Portugal

Lietuva

Lietuva

Россия

Россия Deutschland

Deutschland

Britain

Britain

Україна

Україна

France

France

Sverige

Sverige

Italia

Italia

Norway

Norway

Denmark

Denmark

Romania

Romania

한국

한국

中国

中国

ประเทศไทย

ประเทศไทย

中国香港

中国香港

Israel

Israel

中國臺灣

中國臺灣

India

India

پاکستان

پاکستان

پශ්රී ලංකා

پශ්රී ලංකා

ジャパン

ジャパン

Australia

Australia

New Zealand

New Zealand

South Africa

South Africa