Laser engraving on acrylic has surged in popularity due to its precision, versatility, and the stunning results it produces. As a material, acrylic offers remarkable adaptability for various creative applications, making it an ideal choice for projects ranging from personalized gifts to intricate designs.

With laser engraving technology and laser engraving machine, users can unlock new dimensions in creativity, achieving detailed patterns and designs on acrylic surfaces with exceptional accuracy. This article will delve into the specifics of acrylic laser engraving, exploring the techniques, the types of acrylic that work best, and the machines that make it all possible.

1. What is Acrylic Laser Engraving?

Acrylic laser engraving refers to the process of using a high-powered laser to etch or mark a design onto the surface of acrylic sheets. This technology has gained significant traction in recent years due to its ability to produce intricate, detailed, and permanent markings on a variety of materials, particularly acrylic. The precision of laser engraving allows artists, manufacturers, and hobbyists alike to create designs that are both visually striking and lasting.

2. How Does Laser Engraving Acrylic Work?

Laser engraving on acrylic utilizes a focused laser beam that interacts with the surface of the material. The laser vaporizes or melts the acrylic to create precise marks. Understanding the mechanics behind this process is key to achieving optimal results.

2.1. Why Laser Engrave Acrylic?

Laser engraving offers distinct advantages over traditional engraving methods. The precision provided by lasers ensures high-quality results, with no physical contact between the machine and the acrylic material. This reduces the risk of material damage, such as cracking or deformation. Moreover, laser engraving is highly customizable, enabling intricate designs, logos, and text to be applied to acrylic with ease.

The speed of laser engraving is another significant benefit. The process is faster than conventional engraving, and the accuracy of the laser ensures that designs are transferred to the acrylic exactly as they appear on digital files, with minimal adjustment needed.

2.2. The Science Behind Acrylic Laser Engraving Technology

Laser engraving technology operates by focusing light energy onto the surface of the acrylic material. The laser beam heats the area it contacts, causing the material to evaporate or burn away. The depth and intensity of the engraving can be controlled by adjusting the laser’s power, speed, and frequency. For acrylic, this is particularly important as the material can be sensitive to heat, requiring careful calibration to prevent warping or discoloration.

The laser’s precision allows for fine details to be etched onto the acrylic, making it suitable for a wide range of applications—from delicate patterns to complex logos. The process is also non-mechanical, reducing the likelihood of errors that can occur with traditional cutting or engraving methods.

3. Types of Acrylic That Can Be Processed by Laser

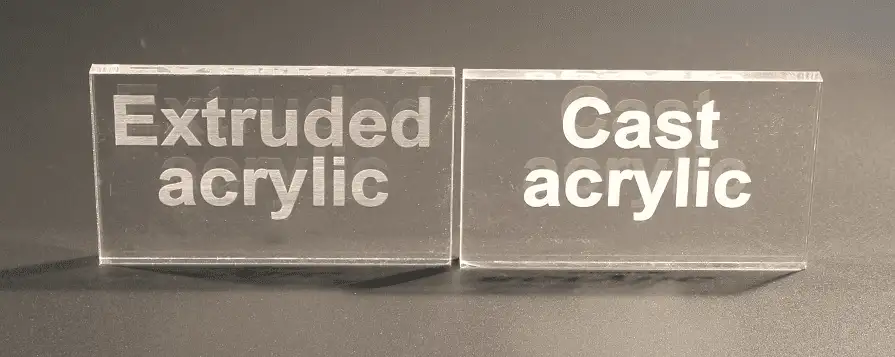

3.1. Understanding Cast Acrylic

Cast acrylic is created by pouring liquid acrylic into molds and allowing it to cure. This manufacturing process gives cast acrylic its superior optical clarity and consistent molecular structure, making it ideal for high-quality applications.

Key Features of Cast Acrylic:

- • Optical Clarity: Offers crystal-clear transparency, making it perfect for displays, signage, and high-end products.

- • Enhanced Durability: Resists cracking and crazing under stress, making it suitable for intricate laser engraving and cutting.

- • Variety of Options: Available in a wide range of colors, textures, and thicknesses to match diverse project requirements.

- • Temperature Resistance: Better withstands high temperatures compared to extruded acrylic, ensuring long-lasting performance.

Applications of Cast Acrylic:

- • Custom awards and trophies

- • High-quality signage

- • Decorative and artistic designs

- • Aquarium panels and windows

3.2. Exploring Extruded Acrylic

Extruded acrylic is produced by pushing acrylic resin through rollers to form sheets. This continuous process makes it more cost-effective and uniform in thickness compared to cast acrylic.

Key Features of Extruded Acrylic:

- • Cost-Effective: More affordable due to its efficient manufacturing process, making it a practical choice for large-scale projects.

- • Uniform Thickness: Consistency in thickness ensures reliable cutting and fabrication results.

- • Lightweight: Easier to handle and transport, especially for larger designs.

- • Polished Finish: Produces clear and smooth edges when cut, ideal for functional or industrial applications.

Applications of Extruded Acrylic:

- • Point-of-sale displays

- • Protective barriers and screens

- • Storage containers

- • Prototyping and fabrication

Comparing Cast vs. Extruded Acrylic

| Property | Cast Acrylic | Extruded Acrylic |

|---|---|---|

| Clarity | Superior, crystal-clear | Good, but less optical precision |

| Durability | Resists cracking and crazing | Slightly less resistant |

| Cost | Higher | More affordable |

| Thickness Uniformity | Slight variation | Very consistent |

| Suitability for Engraving | Excellent for frosted finishes | Clear, polished engraving |

| Heat Resistance | Better | Moderate |

3.3. Choosing the Best Acrylic for Your Needs

- For Engraving and High-End Projects: Cast acrylic is the ideal choice, offering superior detail and clarity for intricate designs.

- For Budget-Friendly and Functional Applications: Extruded acrylic provides reliable performance at a lower cost, perfect for bulk or industrial purposes.

- For Cutting Projects: Both types perform well, but extruded acrylic’s uniform thickness makes it easier to achieve precise cuts.

The decision between cast and extruded acrylic ultimately depends on your project’s requirements, budget, and desired outcome. Cast acrylic excels in aesthetics and durability, making it the premium choice for artistic and decorative projects. On the other hand, extruded acrylic offers cost efficiency and versatility, perfect for functional applications.

4. Best Laser Engraving Machines for Acrylic

Selecting the right laser engraving machine is crucial for achieving precise and high-quality results, especially when working with acrylic. Among the available technologies, CO2 laser engravers are the industry standard for acrylic due to their exceptional performance in cutting and engraving this versatile material, producing the optimal acrylic laser engraving with remarkable clarity and precision.

Nova Plus

This versatile CO2 laser engraver of Nova Plus delivers unparalleled performance for cutting and engraving acrylic. With a up-to 1200mm/s high-speed processing capabilities and 60W RF laser power, the Nova Plus is a powerful tool for professionals aiming to produce intricate and precise acrylic designs. Its spacious working area accommodates larger projects, making it ideal for signage and decorative panels.

Bolt Pro: As a premium desk laser engraver, the Bolt Pro combines compact design with professional-grade functionality. It features a high-power 30-55 W CO2 laser source, allowing for crisp engraving and seamless cutting of acrylic sheets. The Bolt Pro’s precision optics and efficient cooling system ensure consistent performance, even during extended use, making it a top choice for small-scale workshops or on-demand engraving businesses.

Bolt Pro

5. Case Study of Laser Engraving Acrylic

After the theories, practice makes perfect. Here we are having a case study of an acrylic photo laser engraving.

5.1. Items Required for Acrylic Laser Engraving

- Engraving Material: Transparent Acrylic Sheet

- Engraving Machine: Bolt Pro Laser Engraver

- Engraving Helper: Black Marker Pen

5.2. Step-by-Step Guide for Acrylic Laser Engraving

Step 1. Choose a Piece of Acrylic Sheet

Select an 3mm acrylic sheet. Ensure it is free from cracks or imperfections that may affect the engraving quality. In this case, one more step you need to do is to paint the surface with a black marker pen, which will effectively block the transmission of light through the acrylic. If you want, other colors work as well.

Step 2. Prepare Your Design

Insert the picture in LightBurn, add some design for the acrylic photo frame. Adjust the size and DO NOT MIRROR the pattern since the output is on the surface. However, in other cases of photo laser engraving on acrylic, mirroring the picture is essential, it will make sure the surface smooth.

Step 3. Adjust Machine for Engraving

Set the appropriate parameters on the Bolt Pro, including power, speed, and air blow. In this case, we will use strong air blow, 30% power and speed of 1000mm/s for engraving, weak air blow, 85% power and speed of 100mm/s for cutting the edge.

To explore more recommended Thunder Laser engraving and cutting parameters, refer to the settings which applies to any Thunder Laser machines!

Step 4. Start the Engraving!

First, engrave the picture of your beloved pet on the marked area. When the pattern engraving is completed, you will get a inversed picture, but don’t worry, we are still in the process. Paint the area again, and engrave the pattern again as well as the texts in your design. Then you are getting a living photo for your beloved pet!

Additionally, be aware that the acrylic laser engraving process may release toxic gases. To ensure safety, it is crucial to use an air purifier or wear a protective mask during operation.

6. Acrylic Laser Engraving Application and Ideas

Acrylic laser engraving opens up endless possibilities for creative and practical applications. Its versatility, combined with the precision of laser technology, makes it a go-to material for numerous industries and projects. Below are some inspiring applications and ideas to consider:

6.1. Engraved Acrylic Keychains

Keychains are timeless accessories, and acrylic elevates them to a new level. With a laser engraver, you can create personalized designs, logos, or quotes on small acrylic pieces. These lightweight yet durable keychains are perfect for promotional giveaways, custom gifts, or merchandise.

6.2. Engraved Acrylic Trophies and Awards

Acrylic trophies and awards are popular for corporate events, sports competitions, and academic recognitions. Laser engraving allows you to etch intricate patterns, names, and logos onto clear or frosted acrylic, creating a polished and professional look.

6.3. Engraved LED Light Panels

LED light panels made from engraved acrylic sheets are both functional and visually appealing. The laser creates precise designs on the acrylic, which light up beautifully when backlit. This application is perfect for decorative home lighting, business signage, or even personalized gifts.

6.4. Engraved Acrylic Festival Ornaments

Acrylic ornaments are ideal for seasonal décor and festive celebrations. Laser engraving enables you to craft unique shapes and designs, from snowflakes and stars to custom messages. These ornaments can be used to decorate Christmas trees, party venues, or retail displays.

6.5. Engraved Acrylic Signs

Acrylic signs are widely used in businesses for branding, wayfinding, and advertising. Laser engraving ensures crisp text and graphics, making the signs highly legible and visually striking. Options range from minimalist office door signs to elaborate storefront displays.

6.6. Acrylic Jewelry and Fashion Accessories

From engraved acrylic pendants and earrings to cufflinks and bracelets, the possibilities for creating stylish and unique fashion accessories are endless. Laser engraving allows for intricate detailing, giving these items a high-end, customized appearance.

By leveraging the versatility and precision of laser engraving, acrylic becomes a medium for endless creativity and functionality. Whether for personal projects, professional use, or commercial ventures, the potential applications are only limited by your imagination.

Conclusion

Acrylic laser engraving offers an exceptional way to create detailed and personalized designs on a versatile material. By understanding the intricacies of the engraving process, selecting the right type of acrylic, and utilizing the best machines for the job, anyone can unlock the creative potential of this innovative technology. Whether you’re an artist, a business owner, or a hobbyist, laser engraving on acrylic provides endless opportunities to create something unique and lasting.

FAQs About Acrylic Laser Engraving

Q1. What is the difference between engraving and cutting acrylic?

Engraving creates surface designs, while cutting slices through the acrylic to create shapes or outlines.

Q2. How do I clean and maintain laser-engraved acrylic products?

Use a soft cloth and mild soap with water. Avoid abrasive cleaners to prevent scratches.

Q3. Can colored acrylic be used for laser engraving?

Yes, colored laser engraving also works on acrylic, but results vary based on color and type. Transparent and light-colored acrylics often produce better results.

Q5. How can I prevent acrylic from cracking or warping during engraving?

Wear safety goggles and a mask, ensure proper ventilation, and avoid touching the machine during operation.

Q5. How long does a fiber laser engraver last?

Use the correct laser settings, avoid excessive power, and ensure the material is flat and secure.

.png) International

International

United States

United States

Brasil

Brasil

Canada

Canada

Costa Rica

Costa Rica

Česká

Česká

Ελλάδα

Ελλάδα

Polska

Polska

Ireland

Ireland

Portugal

Portugal

Lietuva

Lietuva

Россия

Россия Deutschland

Deutschland

Britain

Britain

Україна

Україна

France

France

Sverige

Sverige

Italia

Italia

Norway

Norway

Denmark

Denmark

Romania

Romania

한국

한국

中国

中国

ประเทศไทย

ประเทศไทย

中国香港

中国香港

Israel

Israel

中國臺灣

中國臺灣

India

India

پاکستان

پاکستان

پශ්රී ලංකා

پශ්රී ලංකා

ジャパン

ジャパン

Australia

Australia

New Zealand

New Zealand

South Africa

South Africa