Unlocking Jewelry Making Potential with Laser Machine

- Home

- >

- Choose by Industries

- >

- The Potential of Laser Jewelry

Jewelry has a rich history as the epitome of decorative artistry. Evolving alongside cultural shifts, modern jewelry now reflects personal identity and unique expression. Jewelry laser making machines have revolutionized this ancient craft, democratizing customization and ushering in an era of limitless creativity.

Transformative applications in the jewelry Industry

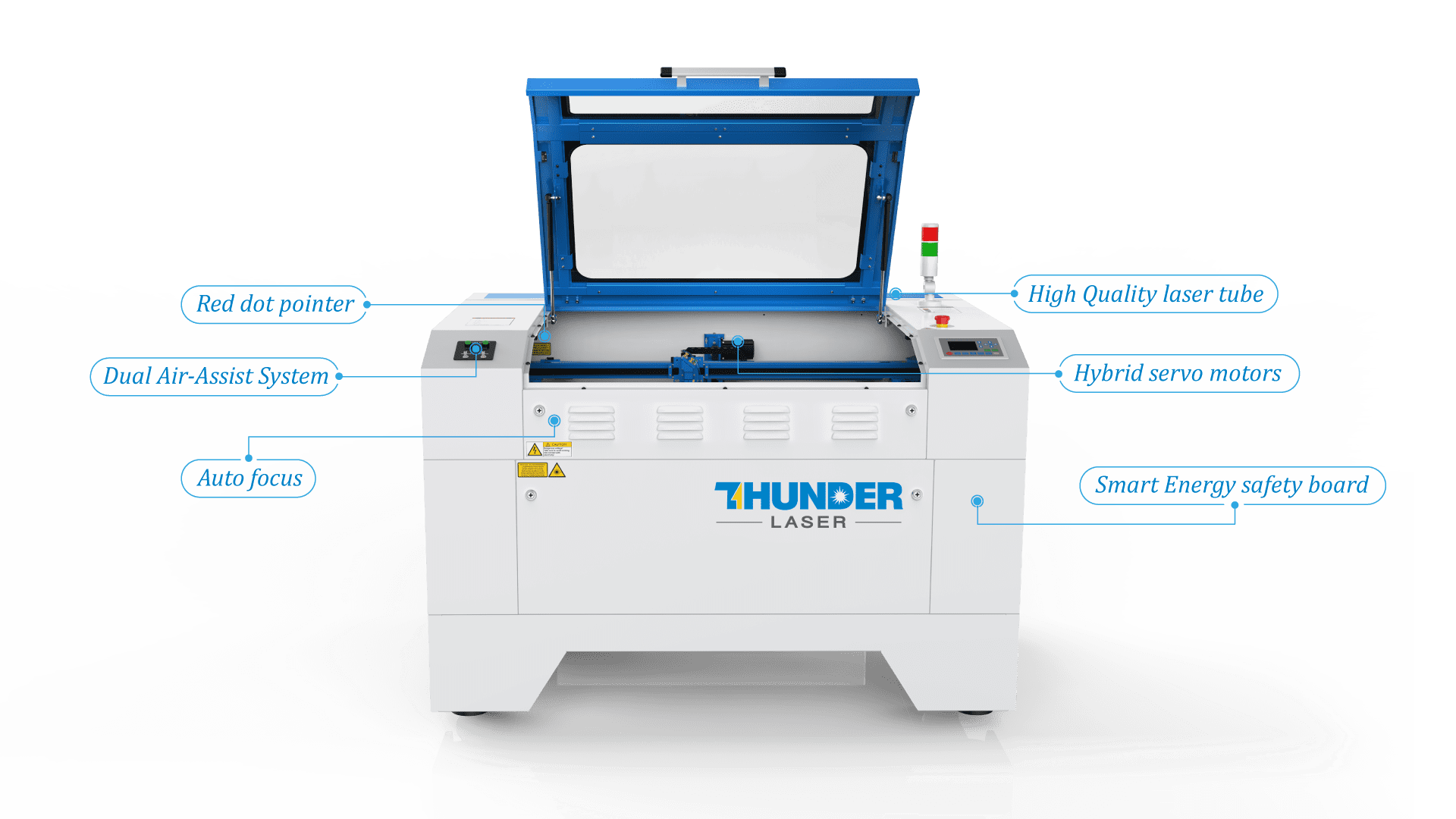

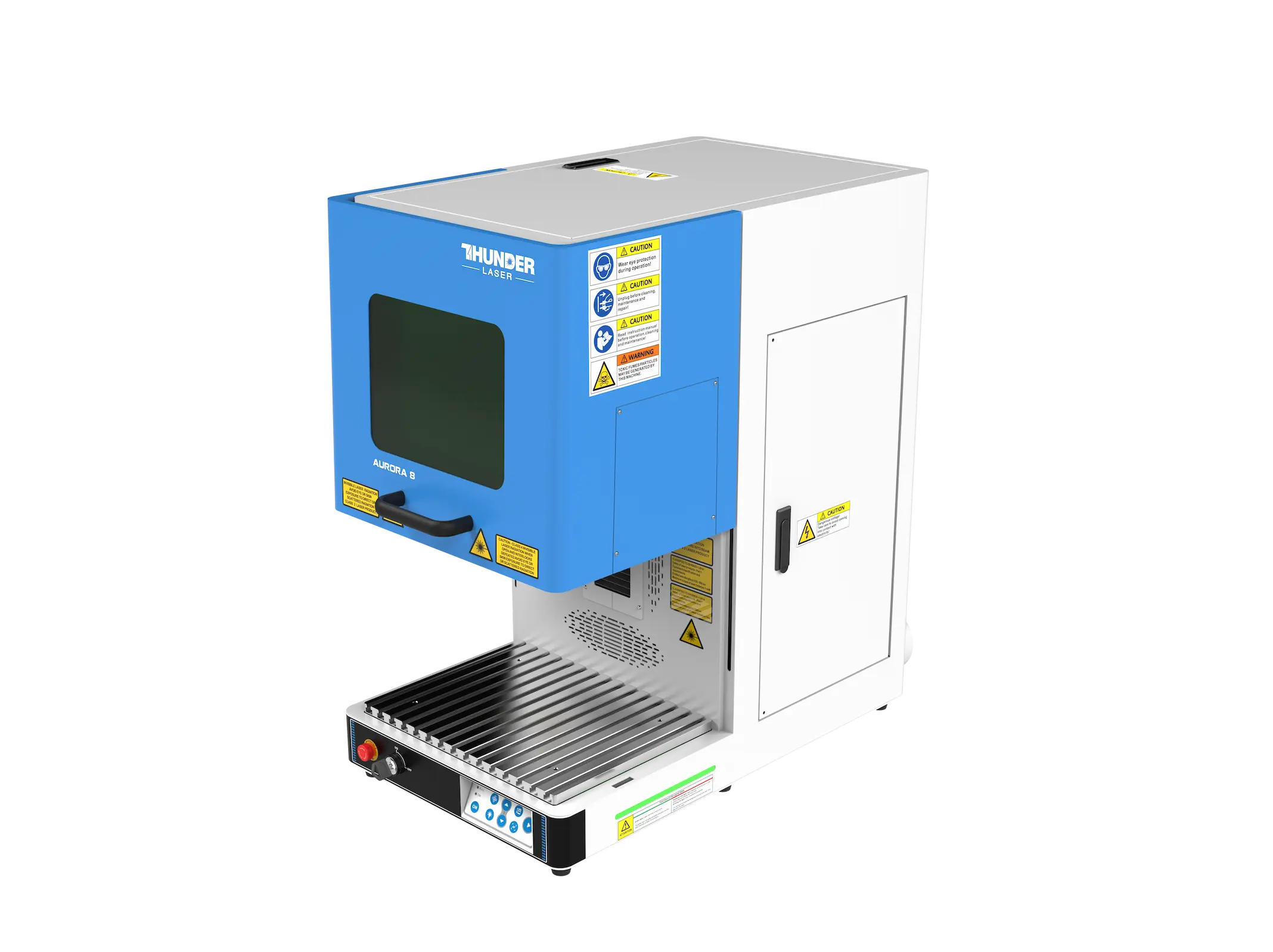

Advantages of thunder laser making machines for jewelry crafting

1. Streamlined Operations

2. Precision Engineering

3. Cost-Effective Solutions

4. Material Diversity

5. Personalized Innovation

Where to source jewelry making materials

Tips for jewelry laser making machine usage in production

Optimizing Efficiency in Jewelry Production

When we use jewelry laser making machines to produce jewelry, the efficiency of producing jewelry one by one can only be slightly improved, but when we learn to mass produce, the efficiency can increase linearly.

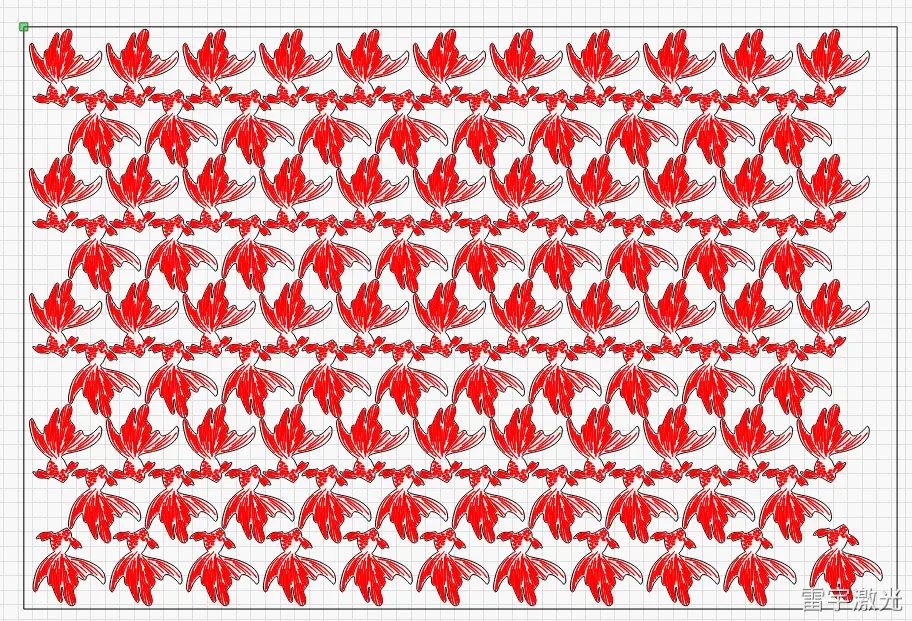

For example, using the goldfish earrings made above, our sheet size is 400 * 600, mm acrylic, and leather is 300 * 300mm. Making a single goldfish earring takes 8 minutes for the acrylic goldfish body and 2 minutes for the leather goldfish head. The two materials are left for about 3 minutes, and making a machine part of the earring takes 13 minutes. If we make each earring separately, thirty will take 390 minutes, which is about 6.5 hours; But when we use mass production, it only takes about two hours to produce 30 goldfish, which is more than three times longer than a single one, greatly increasing efficiency. Moreover, during mass production, people can do other things without being around the machine, and time can be more fully utilized.

The key to improving production efficiency is to learn how to mass produce and free up manpower.

Enhancing Efficiency with Vector Engraving

Cost Reduction Strategies for Jewelry Production

1. Embrace Mass Production: Implementing mass production techniques optimizes resource utilization, saving time and manpower. This streamlined approach maximizes efficiency and minimizes production costs.

2. Precision Technology: Jewelry laser making machines offer precise carving and cutting capabilities, reducing errors and minimizing material wastage. This results in significant savings on material costs, contributing to overall cost reduction.

3. Flexible Layout Design: Adopting a flexible layout strategy allows for efficient material usage. By optimizing the arrangement of jewelry pieces on materials, waste is minimized, further reducing production expenses.

Join the laser revolution in jewelry making

Call us at 86 181 0304 3363 to speak to one of our professionals, or email us at [email protected] / [email protected].

We stand ready to help you find the system that works for you !

.png) International

International

United States

United States

Brasil

Brasil

Canada

Canada

Costa Rica

Costa Rica

Česká

Česká

Ελλάδα

Ελλάδα

Polska

Polska

Ireland

Ireland

Portugal

Portugal

Lietuva

Lietuva

Россия

Россия Deutschland

Deutschland

Britain

Britain

Україна

Україна

France

France

Sverige

Sverige

Italia

Italia

Norway

Norway

Denmark

Denmark

Romania

Romania

한국

한국

中国

中国

ประเทศไทย

ประเทศไทย

中国香港

中国香港

Israel

Israel

中國臺灣

中國臺灣

India

India

پاکستان

پاکستان

پශ්රී ලංකා

پශ්රී ලංකා

ジャパン

ジャパン

Australia

Australia

New Zealand

New Zealand

South Africa

South Africa