The Ultimate Guide to Laser Engraving Stamps

- Home

- >

- Choose by Industries

- >

- The Ultimate Guide to Laser Engraving Stamps

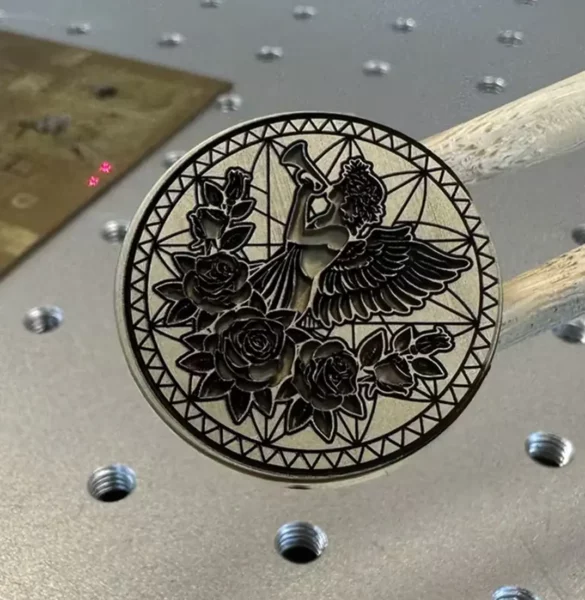

Laser engraving stamps have come a long way from traditional hand carving and mold-based techniques. Today, with the advancement of laser technology, creating custom stamps has become faster, more precise, and highly versatile.

Whether you’re producing business seals, personal stamps, or artistic designs, laser machines offer an innovative solution that simplifies the entire process.

In this article, we’ll walk you through traditional methods, explore how laser engraving has revolutionized the stamp industry, and guide you step-by-step on how to make your own rubber stamp with laser machine.

1. Traditional Methods of Stamp Making

Hand Carving

Metal Engraving

Vulcanization

Hot Pressing Molding

2. How Laser Machines Work in Stamp Making

3. Best Materials for Laser Engraving Stamps

- Rubber: Special laser engravable rubber is commonly used for making custom made rubber stamps. It engraves cleanly and produces clear impressions.

- Polymer: Photopolymer plates can be used for creating stamps, especially in a digital workflow.

- Wood: Hardwood or MDF can be engraved to create a stamp, though it may not be as durable as rubber.

- Acrylic: While not as common, acrylic can be used to make durable stamps.

- Leather: Engraved leather can be used for custom stamps, particularly for crafts and artistic purposes.

4. Advantages of Using Laser Machines in Stamp Making

When it comes to stamp making, laser machines offer a range of advantages that enhance precision, speed, customization, and durability—making them an ideal solution for both personal and professional use.

4.1. High Precision

4.2. Efficiency

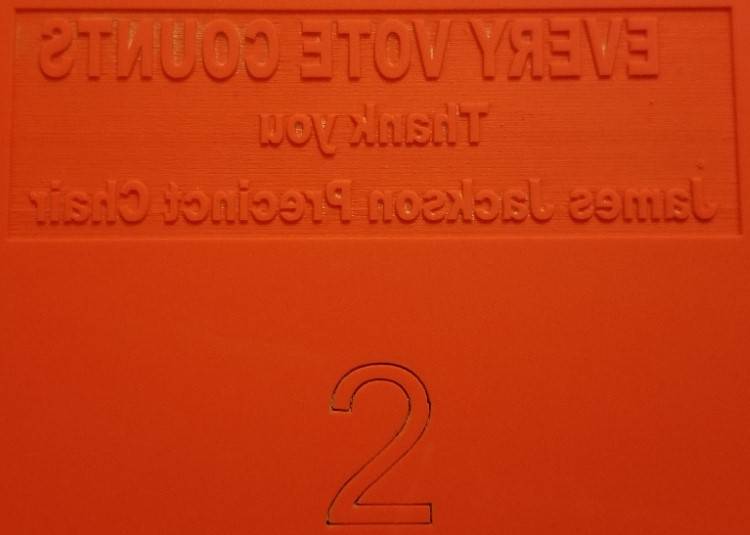

4.3. Customization

4.4. Anti-counterfeiting

4.5. Durability

5. Types of Customization Stamps

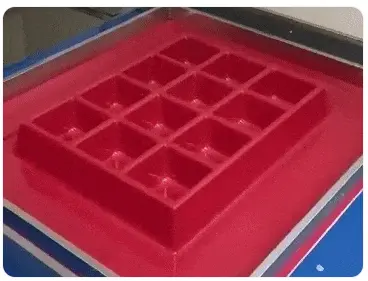

• Rubber Stamps

• POM Stamps

Special etching methods create complex, leather stamp pattern.

• Metal Stamps

• Personalized Stamps

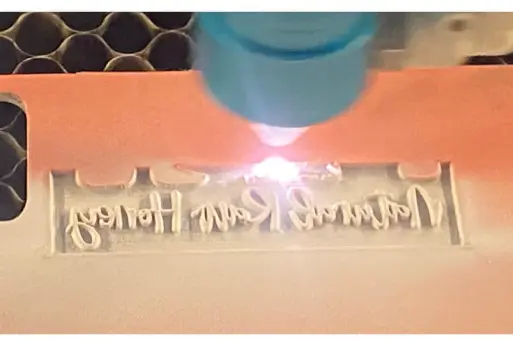

6. How to Make Your Own Rubber Stamp

Step 1: Create your stamp design

Step 2: Select Appropriate Parameters

Step 3: Confirm parameters to achieve the desired effect

Step 4: Group and mirror the design file, with the blue layer representing the illuminated part

Step 5: Choose single or bidirectional filling, noting that one-way filling yields better results

Step 6: Set DPI to 300 for deeper carving

Step 7: Send the File to the Laser Machine

Step 8: Place the Rubber Stamp Board and Select the File

Step 9: Focus Properly and Start Carving

For more details, you can refer to this guide on how to use a laser engraver to make your own rubber stamp

7. Where to Buy the Materials of Laser Engraving Stamps?

- • Johnson Plastics Plus: https://www.jpplus.com/

- • JDS Industries: https://browse.jdsindustries.com/

- • Amazon: https://www.amazon.com/ref=nav_logo

Conclusion

With the help of laser engraving machines, stamp making is no longer limited by traditional molds or manual craftsmanship. You can now create detailed, durable, and fully customized stamps in a matter of minutes.

Whether you’re crafting stamps for business, branding, or creative purposes, laser technology makes the process more accessible and efficient than ever. Ready to get started? Choose your materials, upload your design, and let the laser machine finish the task.

.png) International

International

United States

United States

Brasil

Brasil

Canada

Canada

Costa Rica

Costa Rica

Česká

Česká

Ελλάδα

Ελλάδα

Polska

Polska

Ireland

Ireland

Portugal

Portugal

Lietuva

Lietuva

Россия

Россия Deutschland

Deutschland

Britain

Britain

Україна

Україна

France

France

Sverige

Sverige

Italia

Italia

Norway

Norway

Denmark

Denmark

Romania

Romania

한국

한국

中国

中国

ประเทศไทย

ประเทศไทย

中国香港

中国香港

Israel

Israel

中國臺灣

中國臺灣

India

India

پاکستان

پاکستان

پශ්රී ලංකා

پශ්රී ලංකා

ジャパン

ジャパン

Australia

Australia

New Zealand

New Zealand

South Africa

South Africa