“Yes, our laser can do 3D engraving, like relief.

See below video:

https://youtu.be/zXVZOKx5UWg”

See below video:

https://youtu.be/zXVZOKx5UWg”

“Choosing the right laser can be daunting, but we are here to help! The best way to figure this out is to call us or set up a time to speak to one of our laser experts. They will ask you questions about what you’d like to create and help you find a machine to suit your needs and budget.

The main things to consider are:

How much space do I have?

What materials do I want to cut or engrave?

How thick of material do I want to be able to cut?

What is my budget?

Am I going to be doing production runs or one-off projects?

We’ve written a more in-depth article on this here: https://www.thunderlaserusa.com/choosing-the-right-thunder-laser-your-ultimate-guide/”

Yes, Thunder Laser machines are designed to be user-friendly. In fact, most users are able to start using the machine within a few hours of unboxing. They come with intuitive software interfaces that make it easy for users to create and execute their designs. Additionally, we provide comprehensive training resources to assist our customers.

The short answer is “about as loud as a vacuum cleaner.” For more in-depth analysis, please visit this link: https://support.thunderlaserusa.com/portal/en/kb/articles/how-loud-are-thunder-lasers

Yes! We have a collection of sources that provide free design files here: https://support.thunderlaserusa.com/portal/en/kb/articles/vector-file-download-links

Yes! A laser is just like any other tool. The better you take care of it, the longer it will last. Ideally, the laser is kept in an environment between 55 and 85 degrees with low humidity. However, we have many users that keep them in shops and garages. If ambient temperature drops below freezing, the water in the machine will freeze and break the laser tube. Many users will use a space heater to mitigate this.

“1) You pay the 30% deposit to us

2) We prepare the machine for you after we receive your deposit.

3) We take photos for you when the machine is ready.

4) You pay the 70% balance to us after you see the photos.

5) Take CIF shipping term for example, we send out the machine to you by sea way to your sea port(or by DHL to your door directly according to your needs)

6) We send out all the documents to you to clear the customs and receive the machine.

7) The shipping company will contact you when the machine arrives at your port. You contact with shipping company and ask them to help you to clear customs. And then ask them to find a carrier to send the machine to your door.

8) Everything is done now.”

“Let’s say sending a machine to Hamburg port. Usually, the total delivery time to Hamburg is about 42 days by sea way.

1) The time to prepare the machine is about 7-10 days,

2) We send the machine to the shipping company and the machine will stay in the shipping company’s warehouse for about one week. This is called LCL period.

3) the time from China port to Hamburg port is about 25 days.”

“Usually, we will need about 7-10 days to prepare the order after receiving the payment.

And if shipping by DHL air way, it will need about 7 days to reach you.

So totally it will need about 14-17 days if you choose DHL air way to your door.”

“Warranty of Thunderlaser:

1) The warranty of machine is 24 months.

2) The warranty of laser tube, Laser Power Supply, water chiller, air pump, exhaust system, air compressor and water separator are 12 months.

3) The warranty of lens and mirrors are 30 days from the date of receipt.

4) The warranty is dated from Ex Factory Date.

5) During warranty, Thunderlaser will send the replace parts including shipping without charge. On-site service are availble at a reasonable cost and tech time.

6) When the warranty is over, Thunderlaser will charge at a reasonable price for replacing.

7) Tech support by sending email/phone call/Video/TeamViewer is always free for Thunderlaser user for the whole life.

8) The warranty is only valid for customers who buy machine in the year of 2024.”

Yes. Our Nova laser systems come preset and tested through our quality assurance program. Thunder Laser machines come with a water chiller, air compressor, exhaust fan, tool box with all accessories needed to set up and run.

Only the Nova series requires a water chiller. The water chiller circulates cold water around the laser tube so it doesn’t overheat. But it is super simple to operate! Just fill it with two gallons of distilled water and the machine handles the rest. There are also safety measures in place to make sure the chiller is always on when the laser is running. Only our Nova series machines require a water chiller.

“As long as you know how to design jobs in graphic software, it just takes a few hours for you to become a master of laser machine.

You just need to do some tests to know what speed and power is good for your different materials. Since we’ve provided some of the parameter library, it will save your time. Thunder Laser machines are designed to be user-friendly. Additionally, we provide comprehensive training resources to assist our customers.”

“Here is a video for your reference:

17-How to Send File to Machine

https://www.thunderlaser.com/video/17-how-to-send-file-to-machine/”

“No, our CO2 laser cutting and engraving machines can do both cutting and engraving very well on most nonmetal materials.

Usually you just need one machine for both kinds of jobs. By setting different layers in the laser software, we can input different power/speed/air assist settings for cutting or engraving various thickness and deepth. The dual-air assist also ensures both good cutting and clean engraving results in one go (since most engraving requires low air assist, and most cutting requires high air assist).”

“Yes, every machine will wear. However, you don’t have to worry too much about that with Thunder Laser’s quality build and your regular maintainance. The machine will be working normally at least 2-5 years, we also have customers who have been using their Thunder Laser machines for over 10 years.

Besides the comsumable parts like focus lens, reflective mirrors and laser tubes, most of the accessories are also replaceable. Even after warranty period, we charge reasonable price for the replacement parts and will provide detailed tutorials and instructions.”

“Higher wattage tube with more power output can cut thicker materials, or we can say, for cutting same material, higher watt tube can achieve faster speed.

However, theoretically speaking, the lower watt tube with smaller laser power, which produce smaller laser dots is better for engraving. Take the Nova series for example, usually we suggest 40-80w for engraving, 100-130w for cutting.”

Yes, we have maximum 130watt laser for your choice.

Yes, with an optional rotary attachment you can engrave cups.

Thunder Laser China provides the chuck type rotary attachment, the max support cylindrical object diameter is 10CM diameter. Some of our distributors provde the roller rotaries as well in local, which is able to support larger diameter object. For more details, please feel free to contac us!

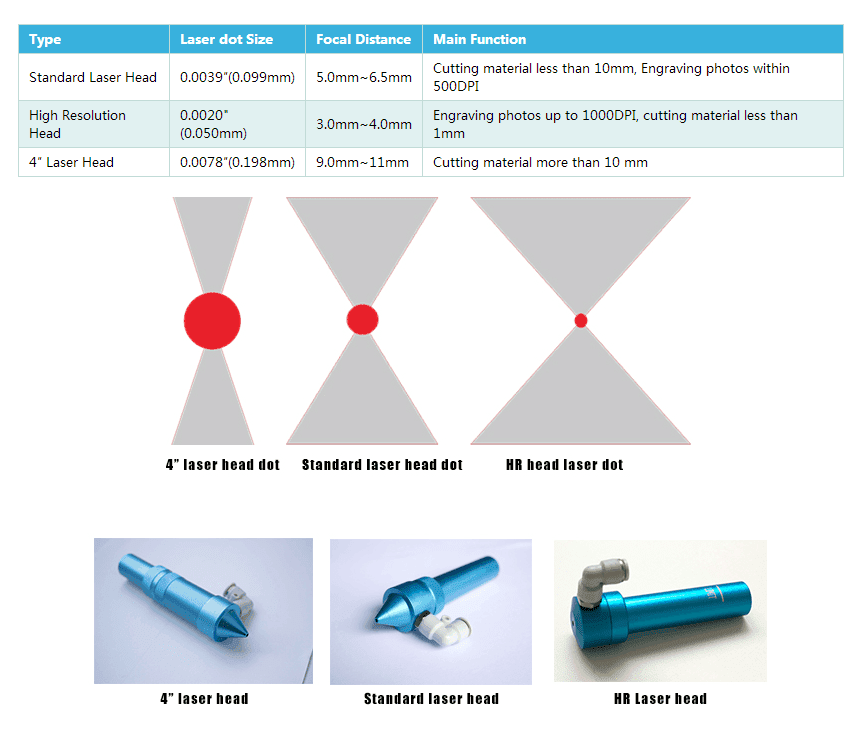

We have 1.5″,2″, 2.5″and 4″ lens for options for Nova and Bolt series. And for Aurora series, we currently have three work areas for option: 110*110mm, 145*145mm, 200*200mm.

“Shorter focal lens will produce smaller final beam spot. That’s why it is better for engraving good quality photos.

And longer focal lens produces greater tolerance and beam-waist radius, is better at cutting thicker materials, it makes cutting edges straighter.”

“For a laser with less than 80W and clean engraving jobs I would recommend the Silicon-Mirrors because they have the best reflectivity (>99%), the drawback is that the coating on it is delicate and not so durable.

For a laser that is doing dirty work (cutting wood 8 hours a day) or working with aggressive chemicals I would recommend the Molybdenum-Mirror. The reflection coating (there is no coating, the Molybdenum is polished) is more resistant, but it gets oxidized. Both are comsumable parts and easy to replace.”

“Yes. We have door protection switches, the laser will stop working if you

open top lid, side doors, rear cover etc. Water protection, Laser will stop working if the water cooling system is not working normally. Emergency stop, Turn off the machine immediately when there’s accident happen. Alarm Lamp, show the work state and tell when the job is done. Heat Alarm detector, the warning alarm goes off once detecting cutting material catches fire, and laser will stop working. The air assist keeps focus lens clean and also helps cool the cutting material.”

The machine comes with a standard exhaust fan. If you need fume extractor, it’s optional.

Yes, Red dot laser pointer is standard feature of all Nova/Bolt series machines.

“The normal color of the laser beam is purple while working. When a tube is

dying, the color will become white.”

“Take the glass tubes for example, the power of the tube is decided by two parameters:

1. The length of the tube, the longer the tube is the more powerful.

2. The diameter of the tube, the bigger the tube is the more powerful.

Usually the higher power the thicker and materials it can cut.”

No need as the laser power we provide is not that high.

“There are two ways to adjust the focus.

1) Manual focus, the machine comes with a focus ruler.

2)Autofocus, use the auto focus feature on Thunder Laser machine.”

Yes, the co2 tube is controlled by the power supply. And the power supply is controlled by the controller. And you can set the power rating easily in the software.

“High resolution Attachment will make the laser dot smaller, thus you can

have much better engraving quality. It is used to engrave high

quality photos.”

“With standard 2″ laser head, the distance between laser head and material is usally 5mm-6.5mm.

If cutting thick material and 6mm distance does not give a good result, you can try adjusting the distance down to about 5mm. For details, please contact our tech team.”

“For cutting thick and flammable materials, it is correct that high pressure air assist helps cool the materials and keep the cutting edges less burnt.

But when engraving, lower air assist can avoid the smoke/ dust from burning the area around the engraved pattern. Usually we do both cutting and engraving in a design file, the Thunder Laser unique Dual air assist allows both cuttng and engraving neat in one go.”

“Theretically the glass tube can last 10000 hours. According to our test, normal lifespan of a laser tube is about 2500-4000 hours according to

how we use and maintain it.”

“Yes, stand of desktop laser machine is an option. We will take it apart

for less expensive shipping and you can set it up with screw after receiving.”

“Different machines have different space requirements. The Bolt can be used as a desktop and you only need about 3’ x 2’ of space. Our Aurora line of fibers can also fit on a desktop. Nova machines are larger and more powerful and require more room. Here’s an article about expample layouts for your reference:

https://support.thunderlaserusa.com/portal/en/kb/articles/example-layouts-for-work-space-considerations#Example_Nova_24_Layout

https://support.thunderlaserusa.com/portal/en/kb/articles/thunderbolt-desktop-machine-3rd-party-stand-and-base-options

It’s suggested to leave about 200mm space for the backside to install the exhaust pipe.

For the other sides, need about 100mm for each, but when you need to replace the parts of the machine, please move it out to a wide place.”

“Yes, we have front and rear pass-through design for on Nova series machine:

https://www.thunderlaser.com/video/pass-through-door-design/“

You have to replace a new glass tube when it’s no longer working. If it’s RF metal CO2 tube, it’s rechargeable.

“We will pack every machine well and it’s seldom out of alignment in transit,

Usually we need to realign the beam path when replacing a laser tube, we have videos and articles about how to align the laser beam:

https://support.thunderlaserusa.com/portal/en/kb/articles/how-to#Quick_Reference_Video_1″

“If the beam is a small round dot, then it is perfect,

but in fact, most of the beam are close to round dot.”

“If you realign the laser beam path by following our lesson and video step by step, It’s not so dangerous,

And to make it safer, yes you are supposed to wear a pair of laser safety glasses.

Please note the most important thing is to get familiar with the process of lesson and video. https://support.thunderlaserusa.com/portal/en/kb/articles/how-to#Quick_Reference_Video_1″

No unsafe materials in the machine and laser tube, and yes, they can be disposed of safety.

“The belts should last at least 3-5year.We have some customers have been using their machines for over 10 years.

When you find the belt loose, you can adjust it by reading our user manual and watch guiding video:

https://www.youtube.com/watch?v=izI9HMzA0ds

https://www.youtube.com/watch?v=yRpCJAmwRw8″

“Yes, machine will get dirty after using for a period time,

You are supposed to clean and maintain it frequently.

For how to clean the machine and keep maintenance,one of our good customer shared an informative video: https://youtu.be/fyKjt7KZtA0″

“For cutting thick material (usually more than 10mm),

4″ lens is good for getting a more straight/smooth cutting edge, it does not mean you can cut more depth. Cutting ability depends on the laser power output and speed setting.”

“For exhausting the air outside,

standard length for the hoses is about 6m

is it ok for you?

if not, can you please tell me how long do you need?

I think we can offer special hoses as option or you may find the extra hose in local.”

Please refer to this instruction about separating the stand of machine to fit through a standard doorway: https://support.thunderlaserusa.com/portal/en/kb/articles/getting-nova-series-machines-through-a-standard-30-doorway

“No need. We can a parameter library in the software, once you find out what settings is best for a certain material,

you can record it in the parameter library. Next time you cut the same material, you just need to read it from the list in the software.”

Both ok, the standard software RDWorks can only run on Windows system, if you use Mac, Lightburn software is a good choice.

Our laser runs on Windows XP/2000/Vista/7/8/10 both 32bits and 64bits system.

But it does not run on Mac OS.

CorelDraw and AutoCAD etc are compatible. You can design all your artworks in these softwares and then send to the RDWorksV8 software to set the parameters easily. Most of our customers recommend Lightburn software. As a laser software, you can design directly on Lightburn, set laser processing power/speed etc and send the files to the machine.

“JPG, PNG, BMP, PLT, DST, DXF, CDR, AI, DSB, GIF, MNG, TIF, TGA,

PCX, JP2, JPC, PGX, RAS, PNM, SKA, RAW”

Yes, you can take a photo and then load the photo to the software directly and engrave it.

Yes, welcome to send us a file or material and we can make a sample test for you to have a look.

Yes, you can start the software without connecting it to a laser machine.

“The corner power should be less than the max power, since the laser head moves slower at corners. For how much less, it is best to do

some tests until you find the best one.”

Yes, it’s ok to use files from Adobe Illustrator, but on RDworks software you will need to export it as DXF format. Then then software can load it.

DXF format, but there’s plug-in for coreldraw, so you can also switch from coreldraw to our laser software directly.

“Co2 lasers like Bolt, Odin, and Nova can’t cut or engrave into metal directly. However, you can leave a permanent mark on them using something like Cermark. You spray the metal with this “paint” then laser over it. It will leave behind what was lasered over.

Our fiber and UV lasers in the Aurora lineup can mark, engrave, and cut directly into metal.”

“Take acrylic for example, Max cutting thickness:

40watt:10mm

60watt:13mm

80watt:18mm

100watt: 20mm

130watt: 25mm

Generally speaking, Bolt is best for high-speed engraving. Nova is where you want to be looking if you’re mostly interested in cutting. For metal and polymer (firearms) marking and engraving, please check out our Aurora series machines.”

“No, for cutting metal, you will need at least 300watt laser.

We only focus on cutting non-metals at present.

The Aurora series marking machine can engrave/mark on metal, but it cannot cut metal either.”

“Yes, please download the suggested parameter settings from below link directly

https://www.thunderlaser.com/downloads/”

Yes, we can cut POM. Please tell us the thickness, we will recommend you a suitable machine.

“Thunder Laser machines are versatile and can work with a variety of materials, including wood, acrylic, leather, fabric, glass, paper, rubber, and more. The specific capabilities depend on the model of the laser machine. For the workable materials, please learn the details from our website:

https://www.thunderlaser.com/”

“Please do not cut any material containing chlorine like PVC, Vinyl, etc. and other toxic material. When heated they release chlorine gas.

This gas is toxic and poses a health risk as well as being very corrosive and harmful to your laser.”

Yes

Yes, normally cast acrylic is better than extruding acrylic for laser processing.

“We didn’t test for engraving photos on metal with Thermark before,

and according to our experience, we think it should be not so good,

as you know metal become black after engrave with laser,

for engraving word, logo and simple pattern, it’s good to see it clear,

however, for engraving photos, I am afraid it’s hard to get a gray scale photo.”

“Yes, Anodized Aluminum and ABS are good materials for engraving photos.

if you have good quality suppliers.

(ABS is a kind of plastic, some ABS will be bend after heat by laser).”

No, our laser(co2 laser) can only engrave on surface of material/glass/crystal

Yes, you can do more than one cut, but usually it’s not suggested as the material may be over burned. Most of the time, one cut will get the best cutting quality.

“The material we paste on glass is just a kind of common tissue paper,

since it help us to get a more smooth surface, (no so much rag)

it’s ok, you really needn’t worry about the paper, you just need to make it wet,

and then paste on the surface of glass you want to engrave.

for Thermark, yeah, it’s useful for engraving on metal,

and after you get the laser job down, you can tear the Thermark off,

(there are some types of Thermark, you can visit their website if you like to learn more).”

10-15mm

This depends on many factors, but a small 3” x 3” engraving would take about 2-4 minutes, depending on the machine. You could cut a large 20” x 20” square of thin material in 1-3 minutes, depending on the thickness of material.