1.Laser Machine routine maintenance work

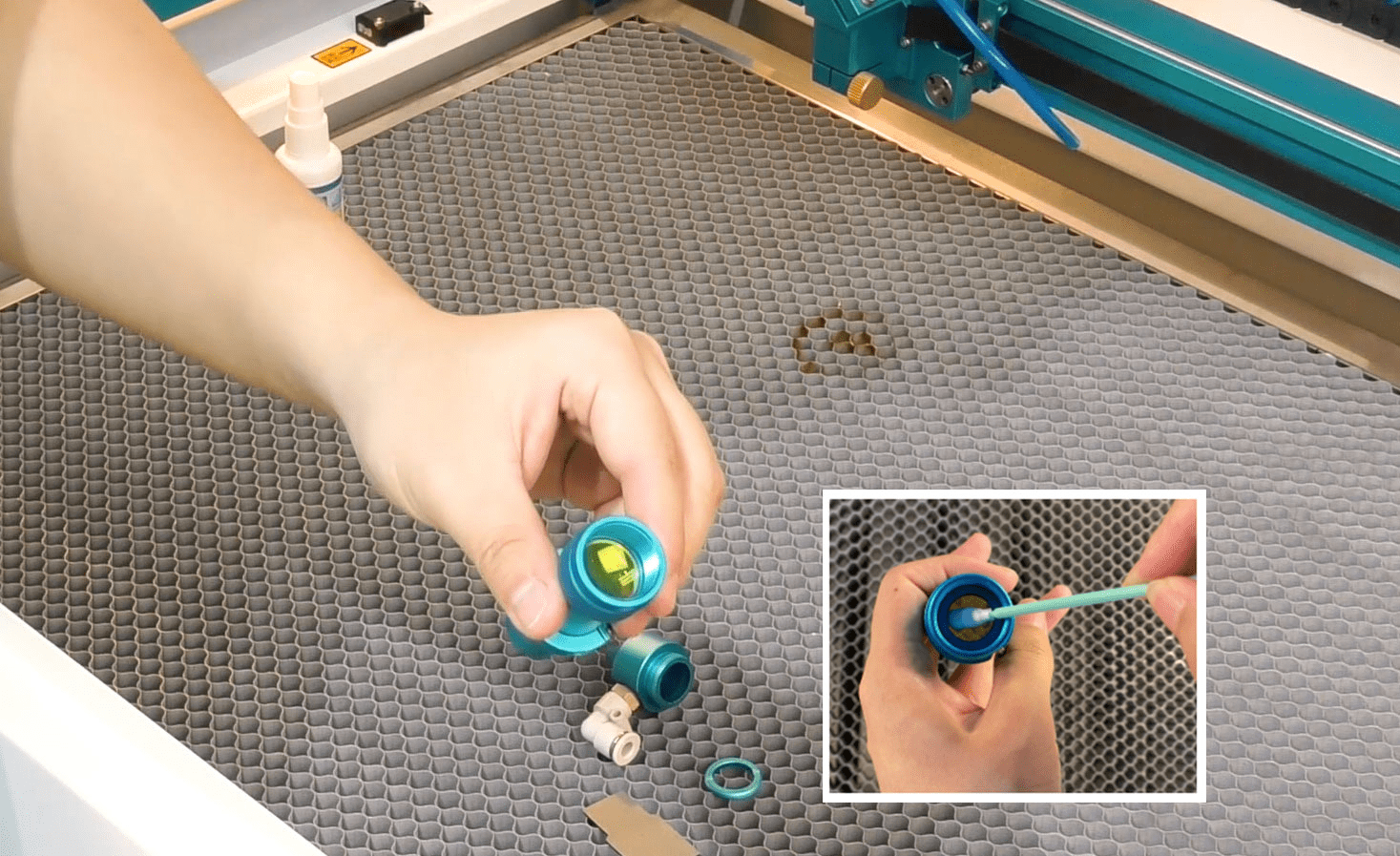

01 Inspecting and Cleaning focus lens

It is imperative that you remove, inspect, and clean your optics before running the machine for the first time.

And also because we have seen the optics (particularly the mirrors) being received tarnished, possibly due to environmental conditions during transport, etc… Every machine is tested before it leaves the factory but the optics can get fouled. We have determined that the optics are not damaged, so clean them up and you will be good to go.

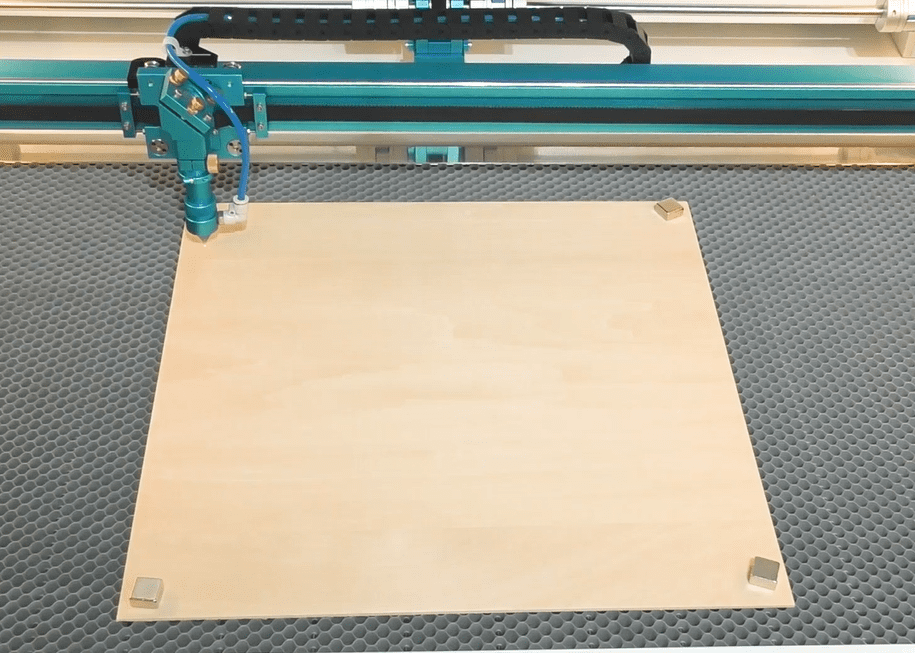

02 Make sure the laser material is flat

Flatness is an often-misunderstood attribute of our intuition. Many of the objects we think of as flat pales in comparison to the surfaces that are actually made flat. In laser machining, flatness is the key attribute for the success of cutting and engraving.

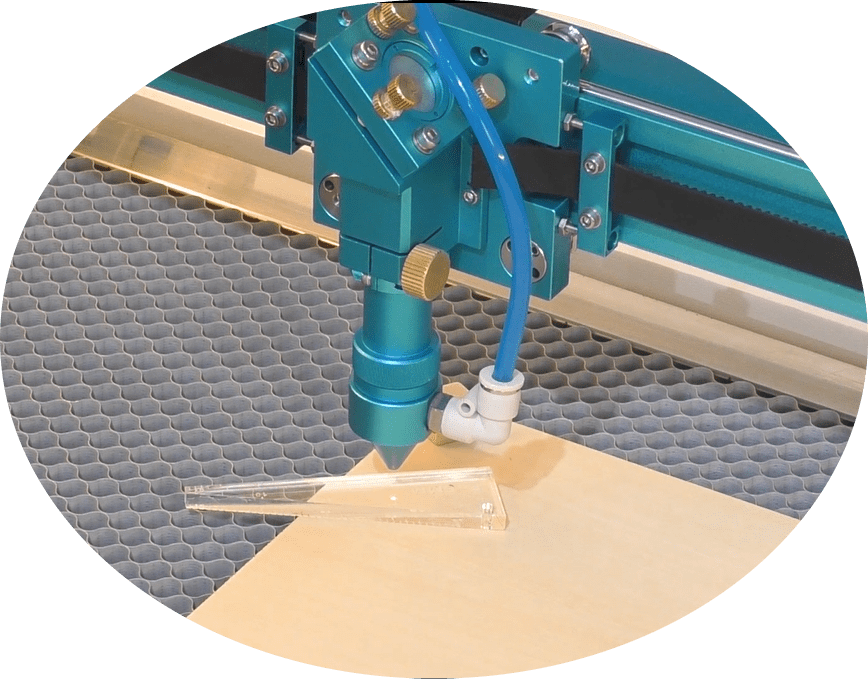

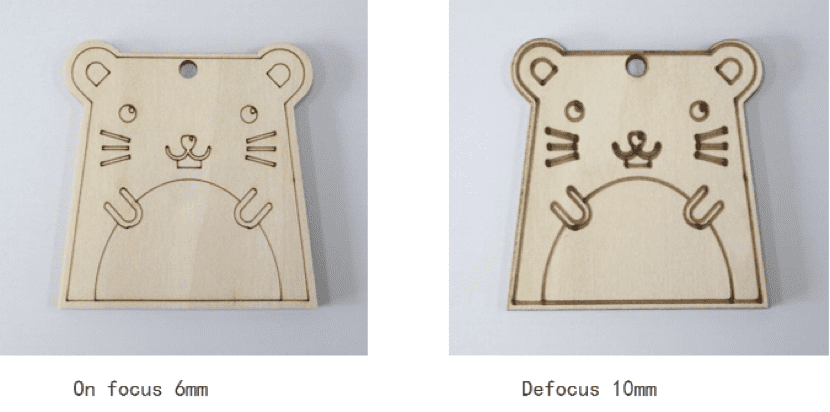

03 Adjust the right focal length

The smaller the spot when the laser beam comes into contact with the material, the better. To get a good cut or engraving you need to know where you laser is focusing correctly. Taking the Thunder laser cutting machine as an example, 6mm is the most appropriate distance.

2. Master more laser processing skills

01 High air compressor is used to assist laser cutting

When cutting thick materials (> 10mm), the use of high air compressor can reduce the carbonization of materials.

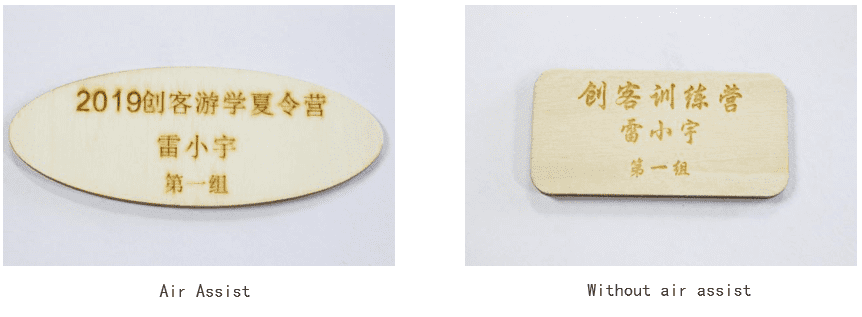

02 Dual Air Assist system

Laser engraving wood

When carving wood, set no blowing, carving effect is the best, the surface of the workpiece is clean and clear.

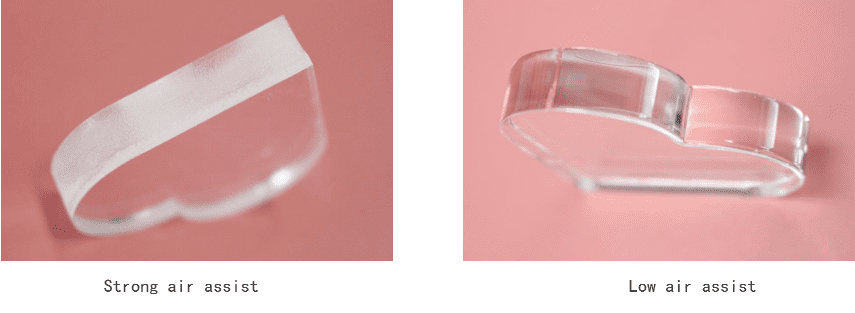

Laser cutting Acrylic

The frosting, is from using too much air. the air is solidifying it prematurely so you are not getting that flame polished edge. When cutting acrylic, you want just enough air to mitigate the flames and expel the resultant gasses.

For an even weaker blowing effect, it is recommended to use it with the 6mm nozzle in the toolbox. By slowing down and reducing blowing, you can cut smooth acrylic!

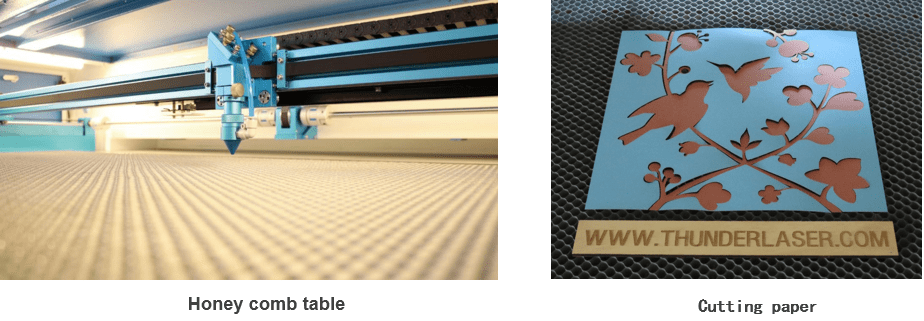

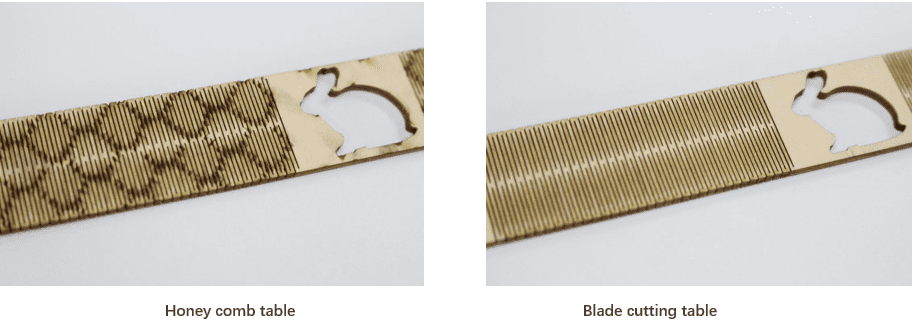

03 using Honey comb or blade cutting table

Before processing, it is necessary to keep the honeycomb platform clean and clean up the fine waste left by the platform. It is more convenient to use tools such as vacuum cleaner.

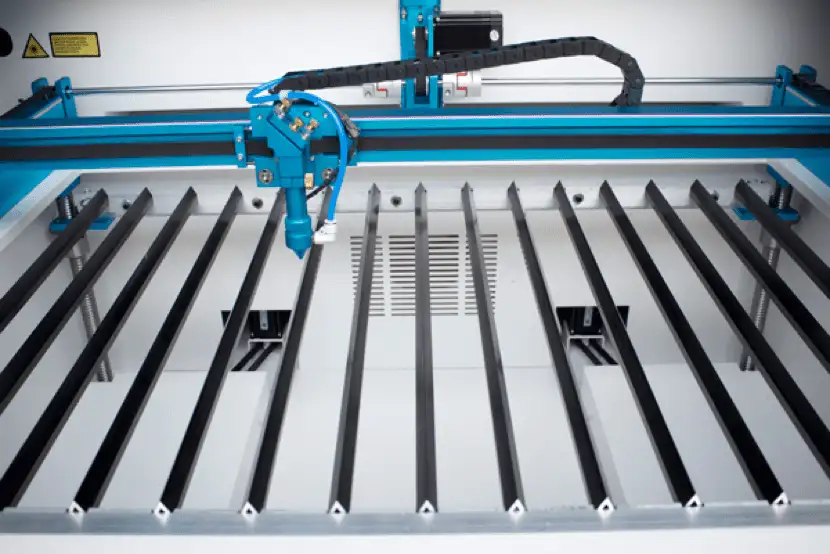

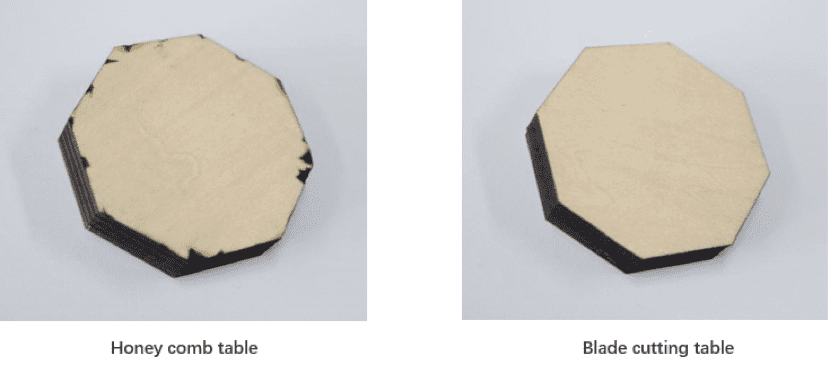

The blade platform is located under the cellular platform. Remove the cellular platform and use the blade platform directly. The density of the blade platform can be adjusted according to the size of the workpiece. The workpiece is suspended in a large area during processing, which greatly reduces the influence of laser reflection and makes the cutting effect reach the best state.

Processing thick materials, such as 10mm wood, due to the high thickness of the material needs to use high power and slow processing, the use of honeycomb plate platform is easy to produce serious reflection, resulting in the bottom of the workpiece yellow, the use of blade cutting table can reduce reflection.

When processing the works of bending structure, because the bending structure is composed of a number of dense line segments, processing on the blade cutting table can reduce the reflection of the back of the material, and the effect is better.

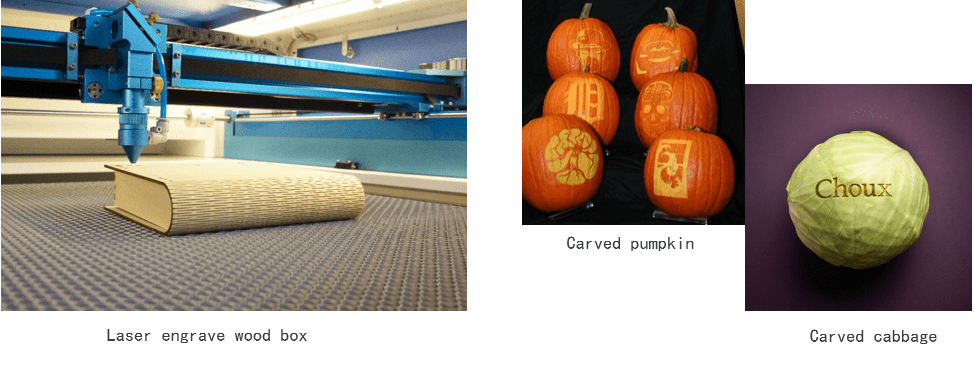

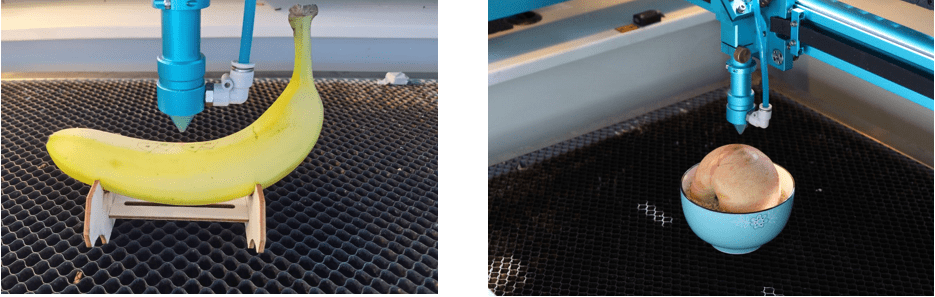

04 Use Motorized table for engraving

When processing large wooden boxes and other large objects, the lifting platform can be used to adjust to the appropriate processing position; At the same time, with a fixed fruit mold, it can also process larger vegetables and fruits, such as big watermelon, pumpkin, etc., which is more creative.

By lowering the lifting platform and setting a larger focal length, the larger focal length and the thicker light spot will deepen and thicken the tracing effect to create a different processing effect.

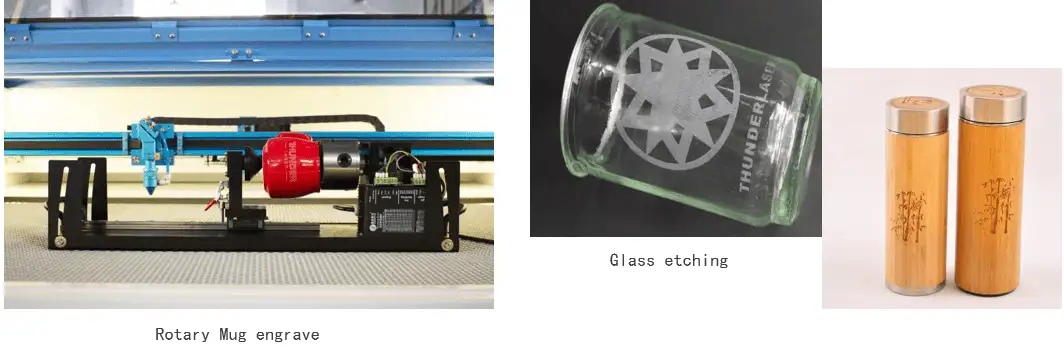

05 Use laser rotary

Rotary shaft tools are used to work cylindrical objects such as glass, cups or bamboo tubes. Because the rotating shaft has a certain height, it needs to be used together with the lifting platform when processing, and the processing platform needs to be properly reduced.

In processing difficult to fix the object, according to the characteristics of the object, make a fixed mold, so that it can be stably fixed in it, easy to process.

.png) International

International

United States

United States

Brasil

Brasil

Canada

Canada

Costa Rica

Costa Rica

Česká

Česká

Ελλάδα

Ελλάδα

Polska

Polska

Ireland

Ireland

Portugal

Portugal

Lietuva

Lietuva

Россия

Россия Deutschland

Deutschland

Britain

Britain

Україна

Україна

France

France

Sverige

Sverige

Italia

Italia

Norway

Norway

Denmark

Denmark

Romania

Romania

한국

한국

中国

中国

ประเทศไทย

ประเทศไทย

中国香港

中国香港

Israel

Israel

中國臺灣

中國臺灣

India

India

پاکستان

پاکستان

پශ්රී ලංකා

پශ්රී ලංකා

ジャパン

ジャパン

Australia

Australia

New Zealand

New Zealand

South Africa

South Africa