- Author: Cathy

1.What tool is best for engraving glass?

Engraving glass with tools can be challenging. Manual engraving tools, such as rotary tools with diamond bits or sandblasting setups, can be used, but they require significant skill and patience to achieve fine details, and the process can be time-consuming. Sandblasting, while effective for larger areas and achieving a frosted effect, lacks the precision needed for intricate designs, requiring protective equipment and setup. Additionally, etching creams can be an alternative, but it tend to produce less precise results compared to lasers. It requires careful application to avoid uneven results and can be hazardous if not handled properly.

Glass laser engraving machine is the most suitable and effective tool for engraving glass. Lasers provide exceptional precision and control, allowing for intricate and detailed designs to be etched into the glass with ease. The process is clean, as it involves no physical contact with the glass, reducing the risk of breakage. Laser engraving also offers consistent results and can handle both deep and surface-level engravings, making it versatile for various applications. Additionally, lasers can create high-contrast, permanent marks that stand out beautifully against the glass.

2. What type of laser machine can engrave on glass?

2.1. UV Laser

Limitations

- Generally more expensive than other laser types.

- Limited to smaller applications due to its specialized use.

2.2. CO2 Laser

Limitations

- Not as resultful as uv lasers.

- If too much power is used, it can create rough results.

2.3. Fiber Laser

Limitations

- Ineffective on transparent materials.

- Additional treatment is required for engraving glass.

2.4. Diode Laser

Limitations

- Insufficient power to engrave or cut glass.

- Not recommended for hard or transparent materials.

How does a laser machine engrave glass?

(1) Laser beam generation

(2) Heat application

(3) Material removal

3. Key features to consider when buying a glass laser engraver

3.1. Laser type

3.2. Bed size

3.3. Software compatibility

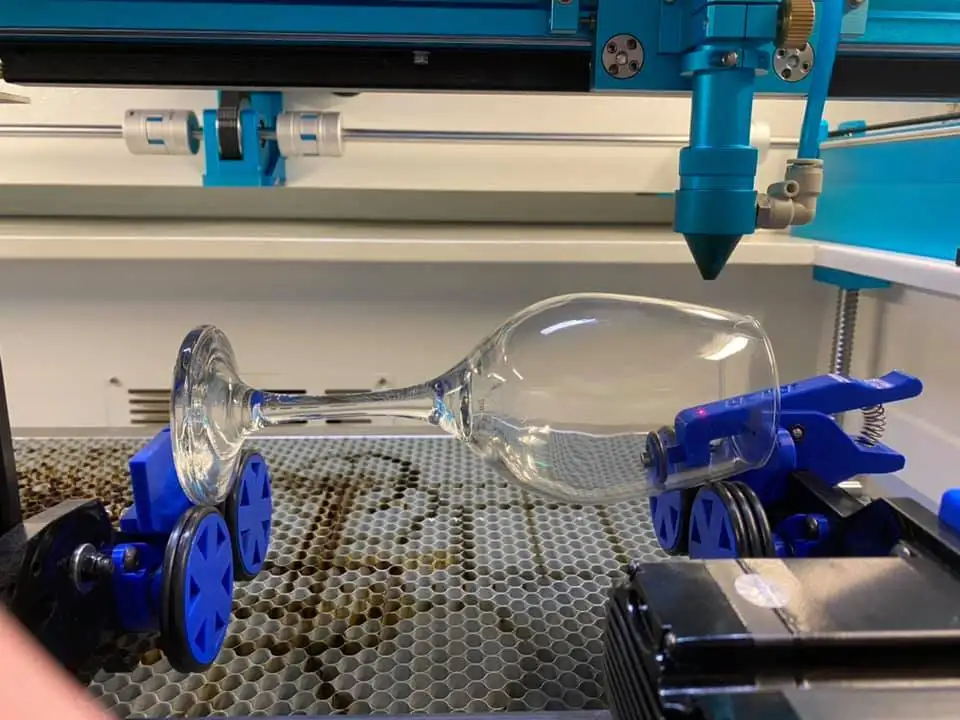

3.4. Rotary device

3.5. Cost Efficiency

3.6. After-sales service and support

How to choose a rotary device for glass laser engraving?

Glass is fragile and varied in shape, so there is something to pay attention when selecting a rotary device for glass engraving. It’s important to ensure that it can securely hold the glass without applying too much pressure, which could cause cracking or shattering.

You can look for devices with adjustable grips or cushioned clamps that can handle different sizes and shapes. Additionally, a rotary device that allows for adjustable speed control is ideal, especially for delicate materials like glass, as slower speeds help reduce vibration and minimize the risk of breakage. High-quality build and rubberized rollers can also provide extra stability and support, making the engraving process safer and more efficient.

4. What is the best glass laser engraver?

We consider the best glass laser engraver is typically a UV laser due to its high precision and ability to create fine, detailed engravings on glass. UV lasers have a shorter wavelength, allowing for minimal heat impact and a clean, crisp finish. This makes it an ideal laser marking for glass for intricate designs, logos, and personalized artwork on glass surfaces.

While CO2 lasers are also used for glass engraving and offer faster processing speeds, they don’t achieve the same level of precision as UV lasers. CO2 lasers are better suited for general engraving tasks but may not provide the fine detail required for more intricate projects.

What materials can UV lasers process?

- Glass

- Ceramics

- Plastics

- Leather

- Anodized aluminum

- Stainless steel

- Paper

- Coated metals

- Wood

- ...

Choose Thunder Laser Engravers for Glass!

For high-quality glass engraving, the Thunder Aurora Laser Marker is your best choice. We offer UV lasers that enable cold marking on glass surfaces with minimal heat production, reaching speeds of up to 8000mm/s while delivering precise engraving results. In addition to marking standard metals, it can work with materials like glass and wood, offering greater versatility compared to fiber lasers. We also provide fiber lasers, primarily for professional metal marking, which can engrave glass with additional treatments like coatings, although in limited applications.

With its large size and high efficiency, the CO2 Nova Laser Cutter is an excellent choice for more productive glass engraving. Capable of speeds up to 1000mm/s, Nova allows for high-volume, large-scale engraving and cutting. While its engraving results may not be as fine as UV laser marking, CO2 lasers can process a wider range of materials and combine both engraving and cutting functions, making it a popular choice for many small laser workshops.

Is it safe to engrave glass with laser machines?

5. What can you create with Thunder Laser?

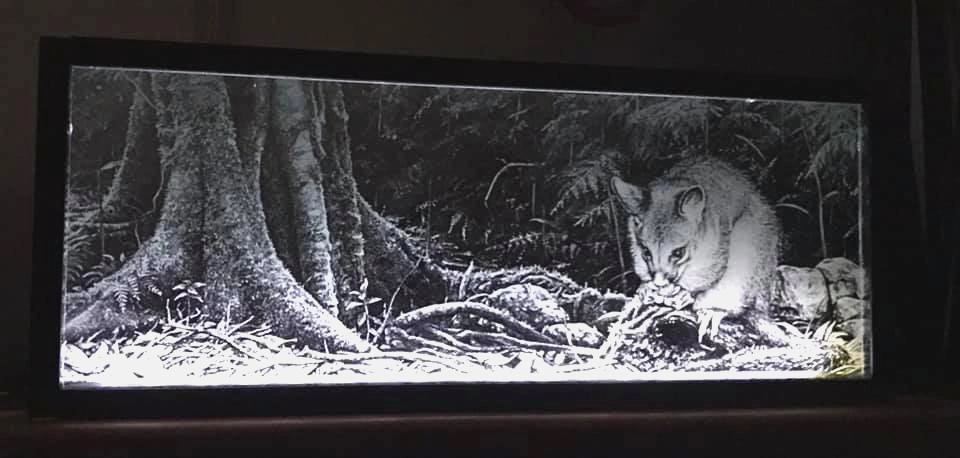

Photo Engraving

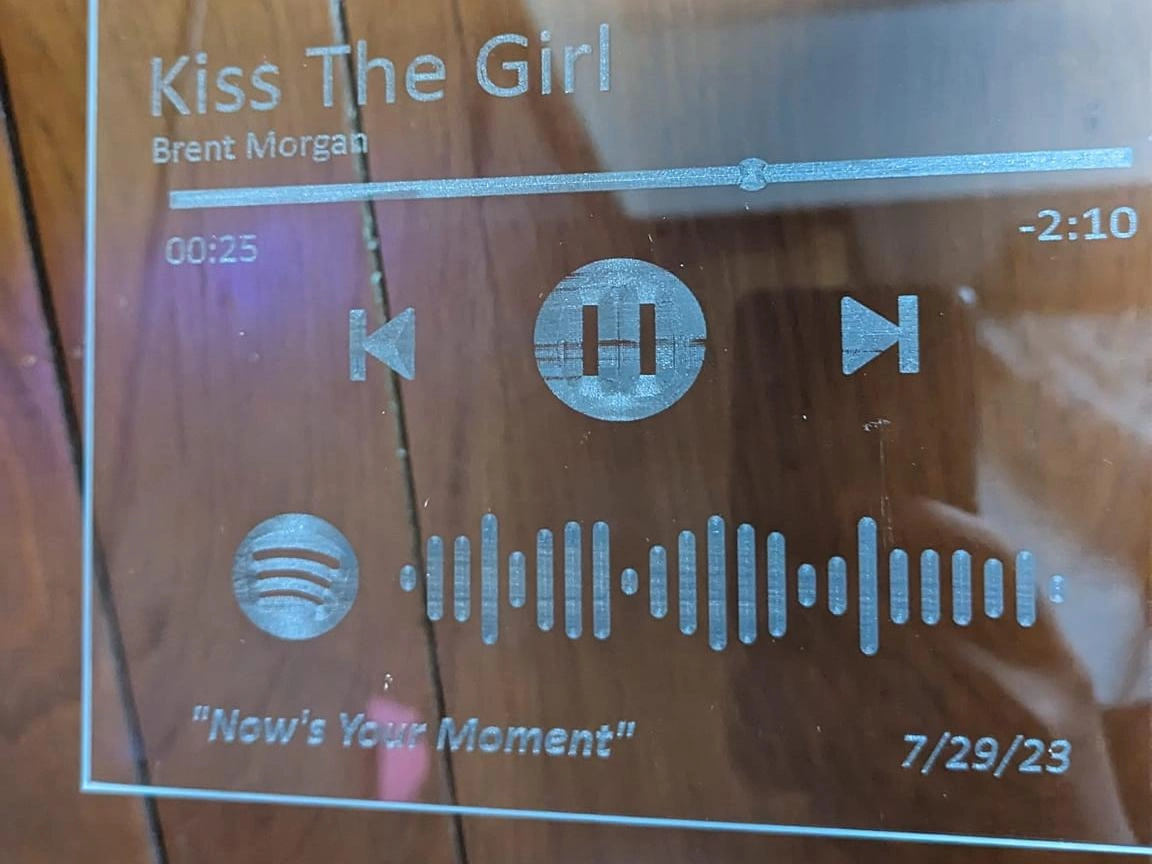

Decorative designs

Glass cups

Coasters

- Tags

.png) International

International

United States

United States

Brasil

Brasil

Canada

Canada

Costa Rica

Costa Rica

Česká

Česká

Ελλάδα

Ελλάδα

Polska

Polska

Ireland

Ireland

Portugal

Portugal

Lietuva

Lietuva

Россия

Россия Deutschland

Deutschland

Britain

Britain

Україна

Україна

France

France

Sverige

Sverige

Italia

Italia

Norway

Norway

Denmark

Denmark

Romania

Romania

한국

한국

中国

中国

ประเทศไทย

ประเทศไทย

中国香港

中国香港

Israel

Israel

中國臺灣

中國臺灣

India

India

پاکستان

پاکستان

پශ්රී ලංකා

پශ්රී ලංකා

ジャパン

ジャパン

Australia

Australia

New Zealand

New Zealand

South Africa

South Africa