Introduction

Are you in the market for a laser cutting machine? If so, you’re in for a treat! This post will provide an overview of what to look for when purchasing a laser cutter and share our top pick for the best machines on the market.

We’ll also give you tips on how to use your new machine safely and effectively. So, whether you’re a beginner or an experienced craftsman, read more about these fantastic tools!

What Is An Industrial Laser Cutting Machine?

An industrial laser cutting machine is a powerful tool that can be used to cut through a variety of materials, including metals, plastics, and glass. Laser cutting machines use a high-powered laser beam to heat the material being cut, causing it to vaporize or melt.

The advantage of using a laser cutting machine over other methods, such as water jet or plasma cutting, is that it can produce a cleaner, more precise cut. Additionally, laser cutting machines can cut through thicker materials than other types of cutting machines.

As a result, they are often used in applications where accuracy and precision are critical, such as in the aerospace and automotive industries.

You can purchase a laser cutter for your home workshop or business. Laser cutters come in a variety of sizes and power levels, so it’s important to choose one that is right for the materials you want to cut and the projects you’ll be working on.

It’s important to consider the features you’ll need, such as the ability to connect to a computer for design files, various cutting modes, and automatic or manual operation.

How Does A Laser Cutting Machine Work?

When you know how a laser cut machine works, you can get the most out of your purchase. Many models of laser cutting machines are controlled via computer software, which allows you to input the design that you want to cut. However, below we will briefly describe the process of how these machines operate.

1. A High-Powered Laser Beam Is Generated.

The laser used in laser cutting machines is usually a carbon dioxide laser, which produces an infrared beam. This beam is then amplified and directed towards the material being cut.

2. The Laser Beam Is Focused On The Cutting Area.

The laser beam is focused onto the cutting area via a series of mirrors. These mirrors direct the laser beam towards the material, where it will begin to cut.

3. The Material Is Heated And Vaporized.

As the laser beam hits the material, it heats it up to extremely high temperatures. This causes the material to either vaporize or melt, depending on its composition.

4. The Laser Cutter Moves Along The Cutting Line.

Once the material has been cut through, the Laser cutter moves along the cutting line so that it can continue cutting. This process is repeated until the design has been completely cut out.

5. The Laser Cutter Cools The Material.

After the cutting is complete, the Laser cutter cools the material so that it can be handled. This is usually done with a stream of coolant or compressed air.

This is a basic overview of how laser cutting machines work. As you can see, these machines are complex pieces of machinery that require a great deal of care and maintenance.

Types Of Laser Cutting!

So, you understand how a laser cutter works, but what about the different types of laser cutters? If you’re in the market for a laser cutter, you’ll need to know about the different types so that you can choose the right one for your needs. Here are the three most common types of laser cutters:

1. CO2 Laser Cutters

CO2 laser cutters are the most common type of laser cutter. They can cut through a variety of materials, including metals, plastics, glass, and wood. CO2 laser cutting machines are available in a variety of sizes and power levels, so you can choose one that is right for your needs.

Features:

– Can cut through a variety of materials

– Available in a variety of sizes and power levels

– Some models can be controlled via computer software

2. Fibre Laser Cutters

Fibre laser cutters are the newest type of laser cutter on the market. They are similar to CO2 laser cutters in terms of their capabilities, but they are more powerful and can cut through thicker materials. Fibre laser cutters are also more expensive than CO2 laser cutters, so they may not be the best option if you’re on a budget.

Features:

– More powerful than CO2 laser cutters

– Can cut through thicker materials

– More expensive than CO2 laser cutters

3. YAG Laser Cutters

YAG laser cutters are the oldest type of laser cutter. They are not as common as CO2 or fiber laser cutters, but they are still used in some industrial applications. YAG laser cutters are less powerful than other types of laser cutters, so they can only be used to cut through thinner materials.

Features:

– Relatively weaker when compared to other types of laser cutters

– Thicker materials will require a different type of blade

– Not as common as other types

Now that you know about the different types of laser cutters, you can decide which one is right for your needs. Laser cutting machines are complex pieces of machinery, so it’s important to do your research before making a purchase.

Application Of The Fiber Laser Cutting Machine

The industrial application of the fiber laser cutting machine is very extensive, and it can be used in many industries. You may not have thought about it before, but the laser cutting machine is used in a variety of industries, including:

Automotive Industry

The automotive industry is one of the biggest users of laser cutting machines. Laser cutting machines are used to cut car parts, such as door panels and dashboards.

Metal laser cutting machines are also used to cut metal sheets, which are then used to make car body panels. In addition, laser cutting machines are used to create car logos and badges.

Aerospace Industry

For the aerospace industry, laser cutting machines are used to cut parts for airplanes and helicopters. Laser cutting machines are also used to create patterns on metal sheets, which are then used to make aircraft wings.

As you can imagine, CNC laser cutting machines play a vital role in the aerospace industry. Some of the world’s most advanced aircraft would not be possible without laser-cutting machines.

Construction Industry

When it comes to the construction industry, laser cutting machines are used to cut metal sheets and pipes. The metal sheets are then used to make the roofs of buildings, while the pipes are used for plumbing.

Not only can laser cutting machines create patterns on metal sheets, but they can also be used to make entire metal sculptures. Construction companies rely on laser cutting machines to get the job done. You can see laser cutting machines at work every time you look at a tall building.

Food And Beverage Industry

Did you know that laser cutting machines are also used in the food and beverage industry? Food is sliced using laser cutting equipment, such as meat and vegetables.

Laser cutting machines are also used to cut packaging, such as food wrappers and drink containers. Furthermore, you can use laser cutting machines to score patterns onto food, like the chocolate chips on cookies.

Medical Industry

Laser cutting machines are used to create implants and prosthetics. Laser cutting machines are also used to cut medical devices, such as stents.

Other medical applications of laser cutting machines include creating patterns on skin and cutting through tissue. Laser cutting machines have a wide range of medical applications.

As you can see, laser cutting machines have a wide range of industrial applications. If you’re looking for a laser cutting machine for your business, make sure you choose one that is suited to your specific needs.

How To Choose A Suitable Industrial Laser Machine?

As a manufacturer, if you are thinking of going with a laser engraver, there are several questions you should consider before making a decision. The first question I would ask is what materials you will be working with.

This will help determine the type of laser system needed – CO2 or fiber optic system.

Next, you will need to determine the maximum material size that will fit inside the machine, which will help narrow down the system model to look at. This can also be determined by the space constraints of your store. After determining the laser source and model size, the next factor to consider is power.

The best way to determine the power requirements of your laser machine is to know the maximum thickness of material that needs to be cut and the number of products you need to engrave in a day. While other factors may come into play, these are the first things to consider.

Most factories will have their own specific requirements for the laser machine. But there are some general factors you should consider when choosing an industrial laser machine. If you’re not sure where to start, here are some things to keep in mind:

Power

The power of the laser machine is one of the most important factors to consider. The power of the laser machine will determine the thickness of the materials it can cut. If you’re looking to cut thick materials, you’ll need a laser machine with high power output.

Conversely, if you’re only looking to cut thin materials, you can get away with a laser machine with lower power output.

Price

Laser machines can be quite expensive, so make sure you have a budget in mind before you start shopping. Laser machines can range in price from a few thousand dollars to tens of thousands of dollars.

Compare prices before you make a purchase. You can do this by shopping around online and talking to different dealers.

Quality

When it comes to laser machines, make sure you’re getting a high-quality machine. This means that the machine should be made from high-quality materials and it should have a good reputation.

You can research the different brands of laser machines to see which ones have the best reviews. You can also talk to other people in the industry to see which brands they recommend.

Bed Size

The bed size will determine the maximum size of the material you can cut. If you’re looking to cut large pieces of material, get a laser machine with a large bed size. If you’re only looking to cut small pieces of material, you can get away with a smaller bed size.

Cooling and Ventilation

Laser machines generate a lot of heat, so ensure that the machine is properly cooled and ventilated. The machine should have a good cooling system to prevent machine from overheating. The machine should be properly ventilated to allow the heat to escape.

Software Requirements

Laser machines will come with their own software. The machine should also have the ability to connect to your computer so you can transfer files.

For example, if you’re using a CAD program to design your parts, you’ll need to be able to transfer the files from your computer to the laser machine.

Floor Space

Laser machines can be quite large, thus you should have enough floor space to accommodate the machine. Laser machines can range in size from a few feet to several yards. You must measure the area where you plan to put the machine before you make your purchase.

Accessories

Laser machines will come with a variety of accessories. These accessories can include things like chucks, jigs, and software. Do some research to see which accessories are included with the machine and which ones you’ll need to purchase separately.

Maintenance

Laser machines require regular maintenance. Make sure you’re familiar with the maintenance requirements of the machine before you make your purchase. Laser machines typically need to be cleaned and lubricated regularly. The laser beam needs to be aligned periodically.

Specifications of Laser

Some machines can cut different types of materials. If you’re looking to cut a specific type of material, make sure the machine can accommodate that material. For example, if you need to cut metal, the machine should be designed for cutting metal.

Laser Resonator

The laser resonator is the part of the machine that generates the laser beam. The quality of the laser beam will depend on the quality of the laser resonator. Get a machine with a high-quality laser resonator to ensure that the laser beam is of the highest quality.

The Cutting Head

You should do some research to see what type of cutting head is included with the machine. Some machines come with a fixed cutting head while others come with a moveable cutting head.

If you’re looking to cut large pieces of material, you’ll need a machine with a moveable cutting head.

The Best Laser Cutter:

We have a lot of experience with laser cutters and we’ve provided a lot of information about them in this guide. Here’s a Laser Cutter that we recommend:

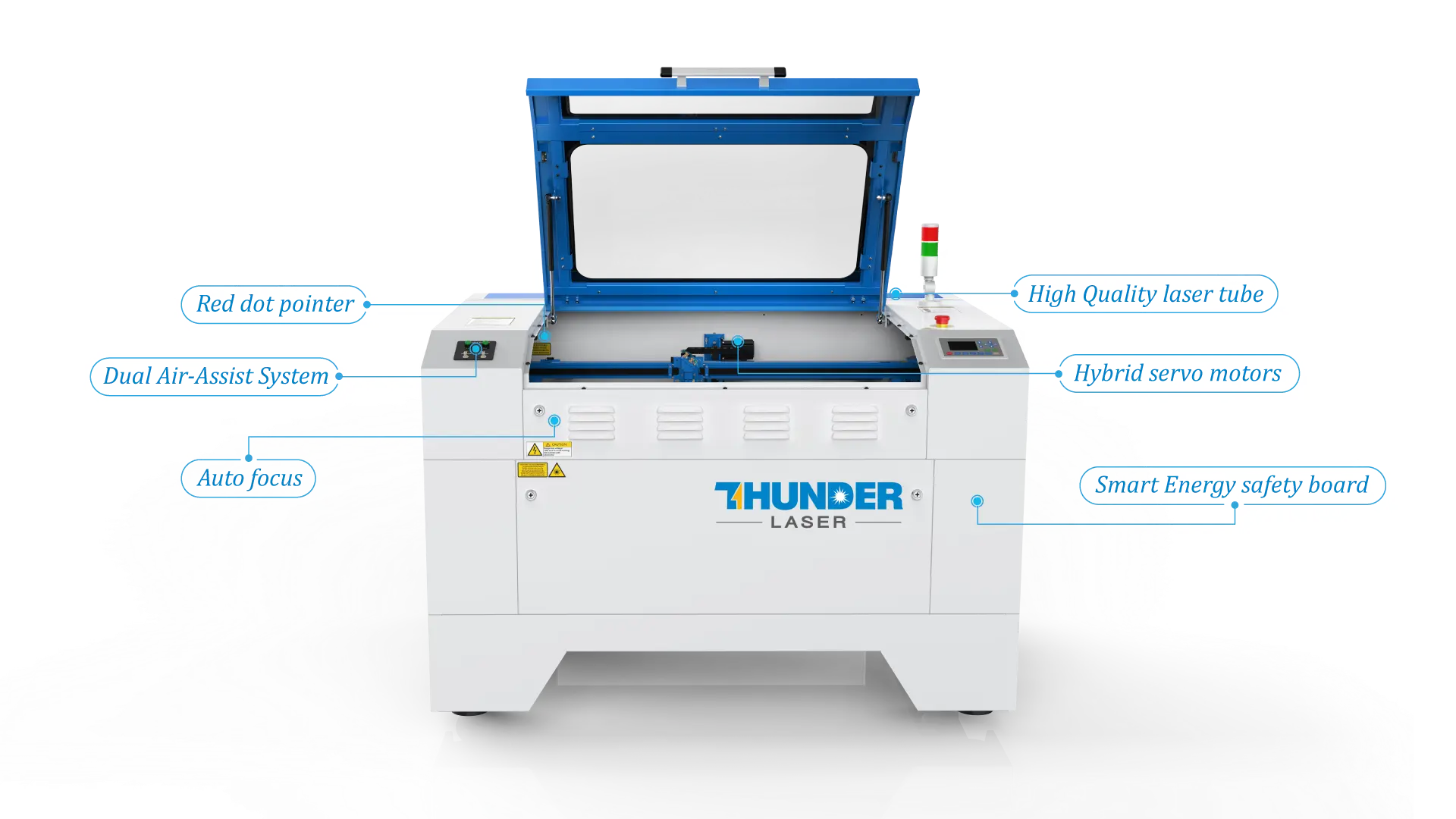

The Nova Laser Cutting Machine is a great choice for anyone looking for a high-quality laser cutter. The machine is made from high-quality materials and it comes with a variety of accessories. It’s also easy to use and it comes with a user-friendly interface.

If you’re looking for a laser cutter that can handle any job, the Nova Laser Cutting Machine is a perfect choice. Its hybrid servo motors make it perfect for both small and large jobs. The machine also has a large bed size, so you can cut larger pieces of material with ease.

Dual air assist nozzles are included with the machine and they help to prevent heat damage. The machine also comes with a venting system to help remove the fumes generated during the cutting process.

The machine is easy to operate and it comes with a user-friendly interface. The machine’s software is compatible with both Windows and Mac computers.

Conclusion

Thunderlaser is your go-to source for all things laser cutting. Our comprehensive guide will help you understand everything there is to know about laser machines and how to choose the perfect one for your needs.

With our expert advice, you can make an informed purchase and start enjoying all the benefits of this versatile technology. Have any questions? Contact us today – we’re always happy to help!

.png) International

International

United States

United States

Brasil

Brasil

Canada

Canada

Costa Rica

Costa Rica

Česká

Česká

Ελλάδα

Ελλάδα

Polska

Polska

Ireland

Ireland

Portugal

Portugal

Lietuva

Lietuva

Россия

Россия Deutschland

Deutschland

Britain

Britain

Україна

Україна

France

France

Sverige

Sverige

Italia

Italia

Norway

Norway

Denmark

Denmark

Romania

Romania

한국

한국

中国

中国

ประเทศไทย

ประเทศไทย

中国香港

中国香港

Israel

Israel

中國臺灣

中國臺灣

India

India

پاکستان

پاکستان

پශ්රී ලංකා

پශ්රී ලංකා

ジャパン

ジャパン

Australia

Australia

New Zealand

New Zealand

South Africa

South Africa