Chiller maintenance ensures that the glass laser tubes of the NOVA series work in good condition for longer. Don’t want your laser glass tube to be damaged in the cold garage because of freezing? Don’t want a tank full of algae? Read the article below to maintain your chillers!

1. Using the Chillers for the First Time

Unscrew the lid of your chiller and fill the empty tank with pure water until the level rises at the green normal scale. And before each task, check that the level is on the green part. It’s a very important part of chiller maintenance.

If the level is down to the red alarm scale, continue to add water; once the level reaches the yellow full scale, open blowing mouth to let overfilling water out. So you’re done with the pre-use work and first chiller maintenance.

- Only pure water can be added to the tank, don't add ordinary water!

2. Routine Chiller Maintenance

Do chiller maintenance once or twice a month. And routine maintenance is very simple, just need to clean the dust screen, open the water inlet cover and blowing mouth to refresh water.

What’s more, remember to check the water volume as you did the first time using after finishing the chiller maintenance.

3. Avoid heat in chiller maintenance

Try to keep the temperature of the machine’s working environment below 27 degrees Celsius and avoid direct sunlight, control air humidity below 70%, that’s enough for chiller maintenance in hot weather!

4. Anti-freeze in chiller maintenance

The ideal operating temperature for the NOVA series is 15-25 degrees Celsius. However, due to the changeable climate, it is inevitable that you will encounter some low temperature days that require special chiller maintenance.

Damage to the laser tube because of cold or other natural causes will not be warranted, so read the related article of chiller maintenance in detail to avoid destruction!

Empty the water tank when the cooler is not used for a long time. If you have to use NOVAs in winter, pay great attention to chiller maintenance. Try to keep the temperature of the workspace above zero degrees Celsius. Setting constant mode heating on the cooler also helps prevent freezing damage.

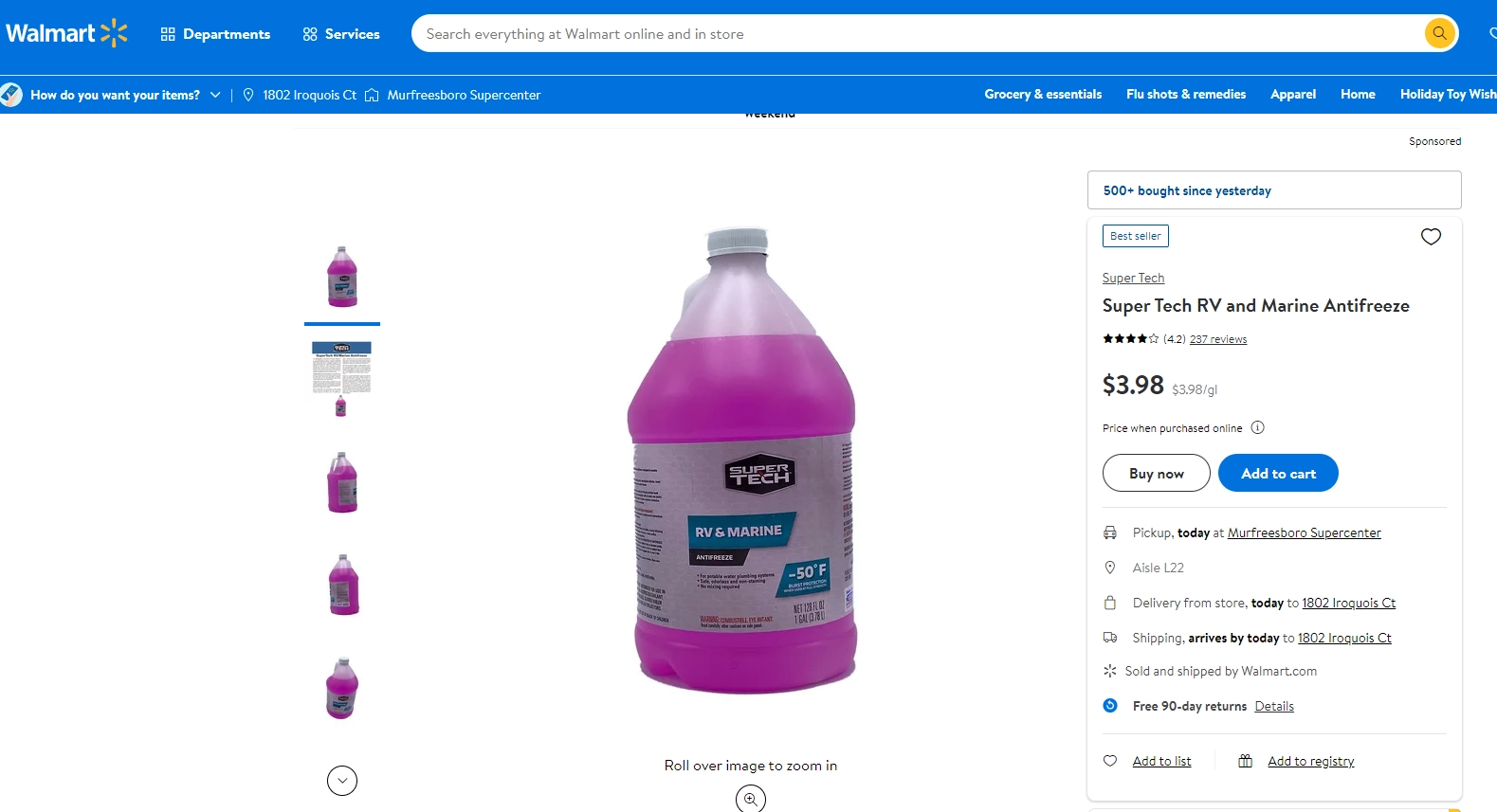

When the temperature of the working environment drops below zero degrees Celsius, antifreeze should be added for chiller maintenance. However, after the temperature returns above freezing, it is necessary to drain the refrigerant completely to prevent corrosion.

Preventing Algae Growth

After the coolant is added to the tank, the nutrients provided may promote algae growth. And prevent algae growth chiller maintenance is required.

Let the algae stay in the natural world, but don’t want to see them in the tanks.To protect the tank from algae, you can add a small amount of algaecide and detergent to maintain the chillers.

.png) International

International

United States

United States

Brasil

Brasil

Canada

Canada

Costa Rica

Costa Rica

Česká

Česká

Ελλάδα

Ελλάδα

Polska

Polska

Ireland

Ireland

Portugal

Portugal

Lietuva

Lietuva

Россия

Россия Deutschland

Deutschland

Britain

Britain

Україна

Україна

France

France

Sverige

Sverige

Italia

Italia

Norway

Norway

Denmark

Denmark

Romania

Romania

한국

한국

中国

中国

ประเทศไทย

ประเทศไทย

中国香港

中国香港

Israel

Israel

中國臺灣

中國臺灣

India

India

پاکستان

پاکستان

پශ්රී ලංකා

پශ්රී ලංකා

ジャパン

ジャパン

Australia

Australia

New Zealand

New Zealand

South Africa

South Africa