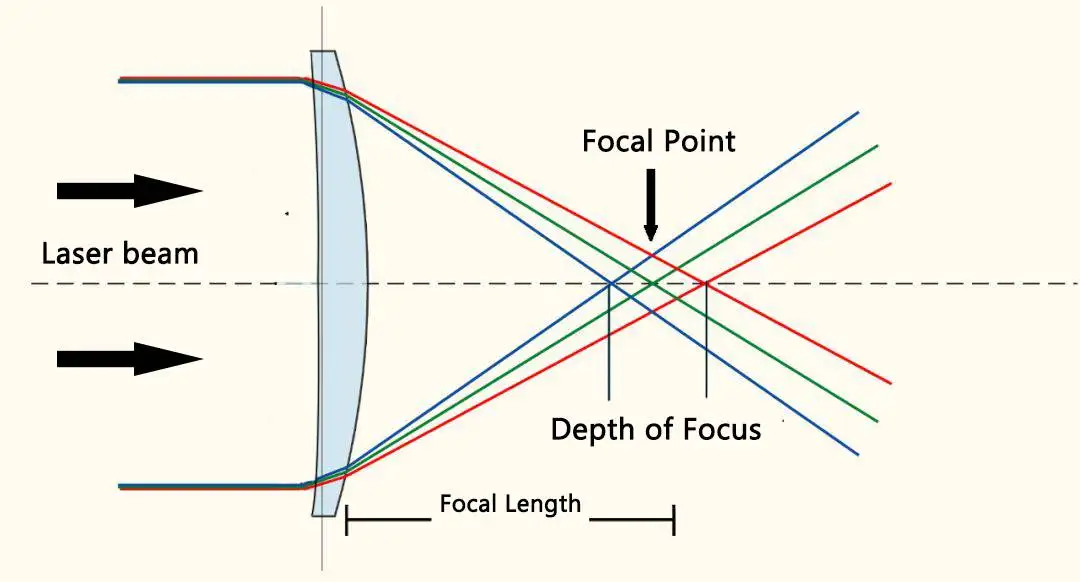

Understanding Laser Lens Principles

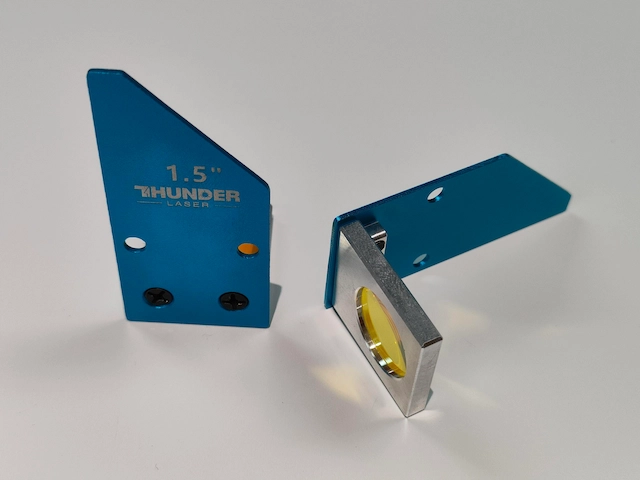

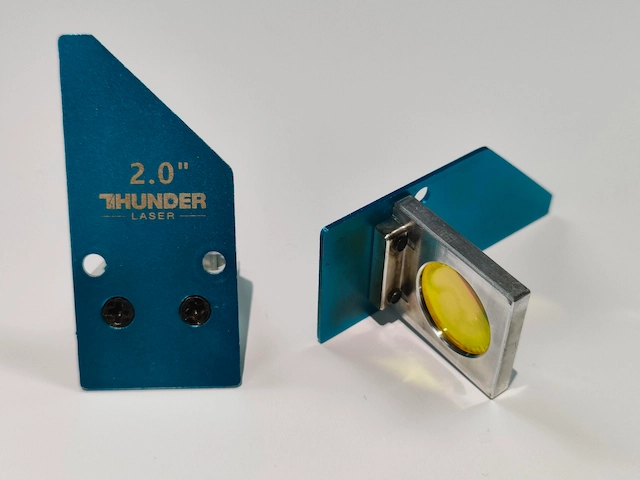

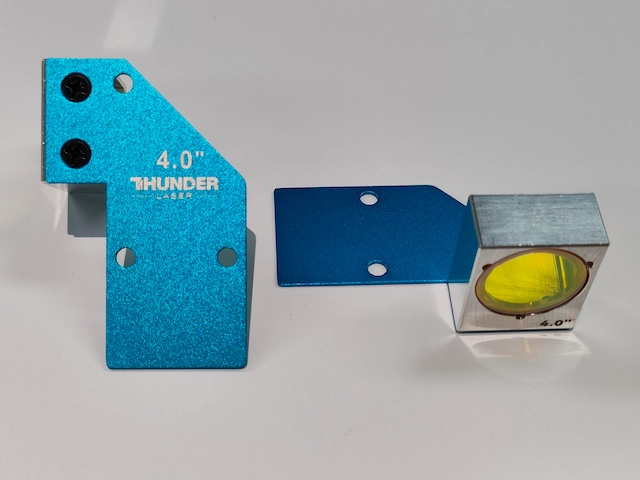

Let’s take a look at what the various models of laser lenses look like. Laser lens models for Thunder laser are classified by focal length, ranging from 1.5 inches to 4 inches. The distance from the center of the laser lens to the focal point of the laser beam is called the focal length.

The smaller the focal length of the laser lens, the more the actual energy output of the laser is concentrated in a small area. However, the laser also has a shallower depth of focus, making it unsuitable for cutting thicker materials.

What are the different laser lenses respectively suitable for

In general, smaller focal length lenses are better suited for engraving extremely fine details, while larger focal length lenses have a deeper depth of focus and are primarily used for cutting thicker materials. Here are specific applications:

When to Use Shorter Focal Length 1.5″ Laser Lens :

The very short focal length of the 1.5” laser lens creates a small laser spot at the point of focus, allowing for very fine engraving detail and high power density. A side effect of this is that due to the small spot, the engraving lines are thinner, which may result in a less uniform engraved pattern; this can be solved by adjusting the DPI. And high power densities may cause heat sensitive materials to curl and distort when engraving over larger areas. Increasing the Z-axis offset or changing to a larger focal length lens can help minimize this effect by enlarging the laser spot.

Using 2.0″ Laser Lens for Engraving:

For engraving tasks, using a 2.0-inch laser lens can be advantageous as it balances detail and performance.

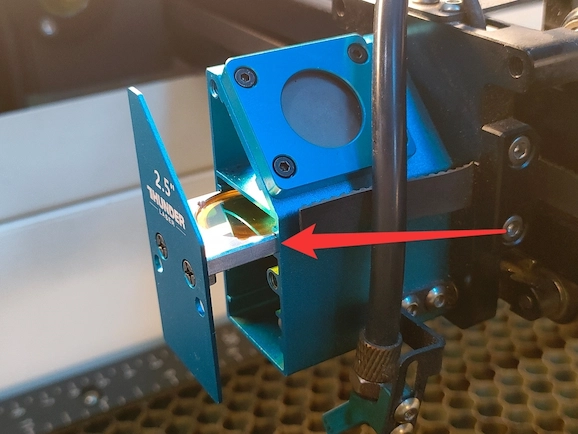

Using 2.5″ Laser Lens for Engraving:

When working with temperature-sensitive materials, choosing a 2.5″ laser lens with a larger focal length reduces the thermal distortion that can occur when engraving large quantities over a large area.

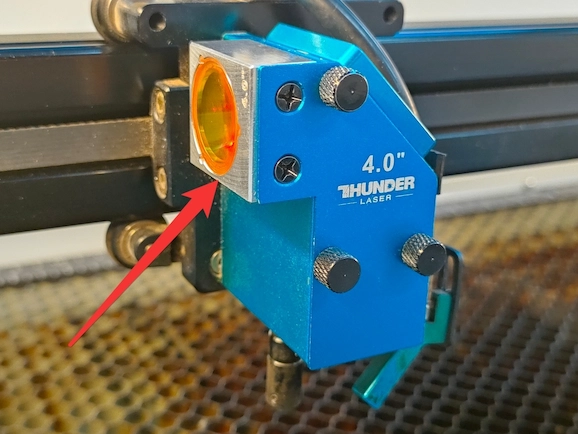

Using the 4.0″ Laser Lens for Cutting:

For cutting materials thicker than one inch, the 4.0-inch laser lens is recommended, as it enables the creation of more vertical cutting edges, enhancing the quality of the cut.

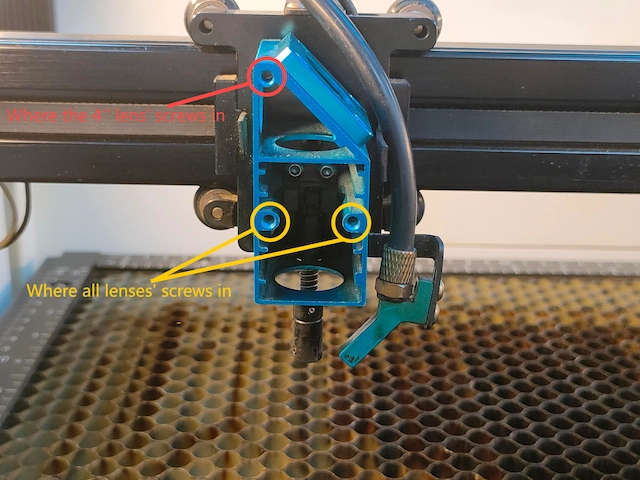

How to Assemble the Focusing Lens

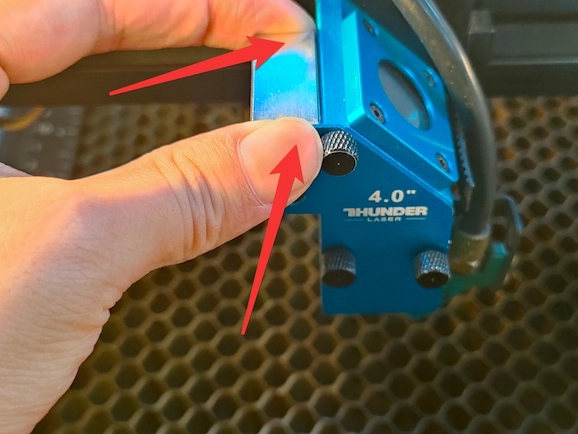

The laser head leaves room for 3 thumbscrews, the part marked in yellow is the one that should be used for all models of focusing lenses, while the red one is only needed when using the 4” laser lens.

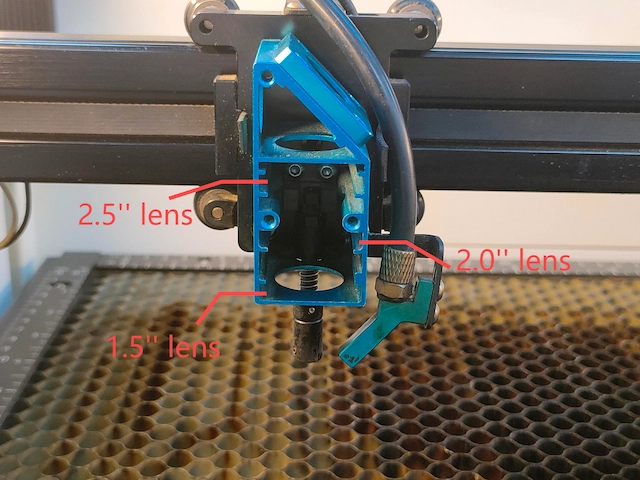

The bolt series has a uniform laser head appearance that ensures that any laser lens used will focus by the same way. However, the different types of lenses are not in the same position inside the laser head.

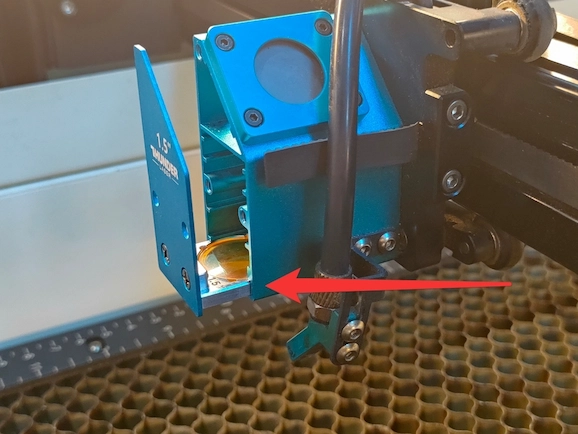

1.5” means that the focusing laser lens has the shortest focal length, so it is mounted at the bottom.

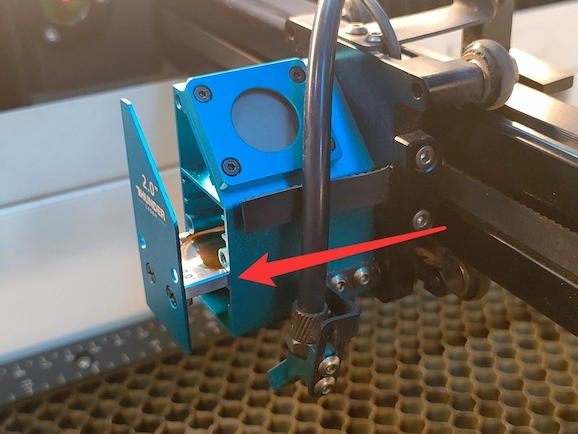

2.0” laser lens inserted just under the thumb screws.

The 2.5” laser lens is inserted above the thumb screws, but not in the slot next to the screws.

4” laser lens position should be before the third reflector, instead of inside the laser head.

Fingers should be pinched around the edges when removing the laser lenses and not touching the lenses.

.png) International

International

United States

United States

Brasil

Brasil

Canada

Canada

Costa Rica

Costa Rica

Česká

Česká

Ελλάδα

Ελλάδα

Polska

Polska

Ireland

Ireland

Portugal

Portugal

Lietuva

Lietuva

Россия

Россия Deutschland

Deutschland

Britain

Britain

Україна

Україна

France

France

Sverige

Sverige

Italia

Italia

Norway

Norway

Denmark

Denmark

Romania

Romania

한국

한국

中国

中国

ประเทศไทย

ประเทศไทย

中国香港

中国香港

Israel

Israel

中國臺灣

中國臺灣

India

India

پاکستان

پاکستان

پශ්රී ලංකා

پශ්රී ලංකා

ジャパン

ジャパン

Australia

Australia

New Zealand

New Zealand

South Africa

South Africa