Recommended settings

| Processing | Speed (mm/s) | Max power(%) | Min power(%) | DPI | Hatch type | Blow type |

|---|---|---|---|---|---|---|

| Engraving | 1500 | 30 | 20 | 300 | one-way fill | weak |

| Cutting | 20 | 80 | 10 | 300 | one-way fill | strong |

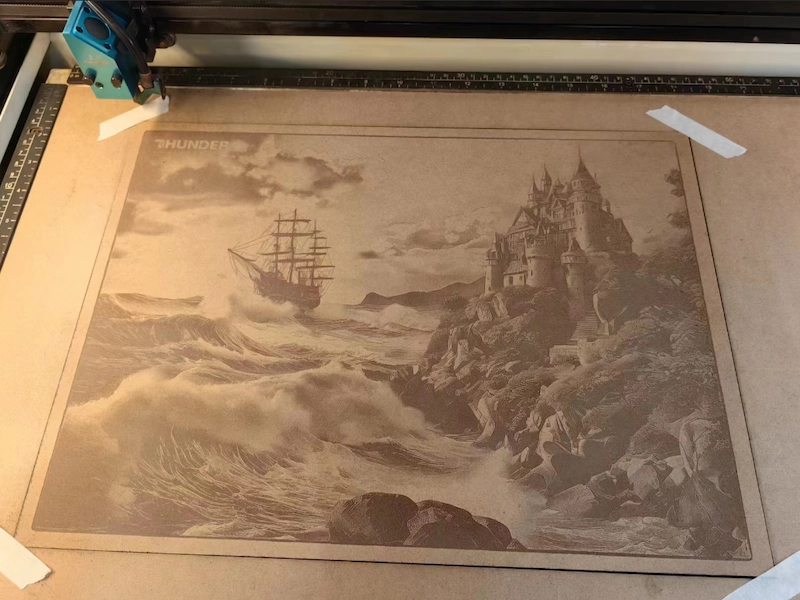

Processing steps

1、File Setup

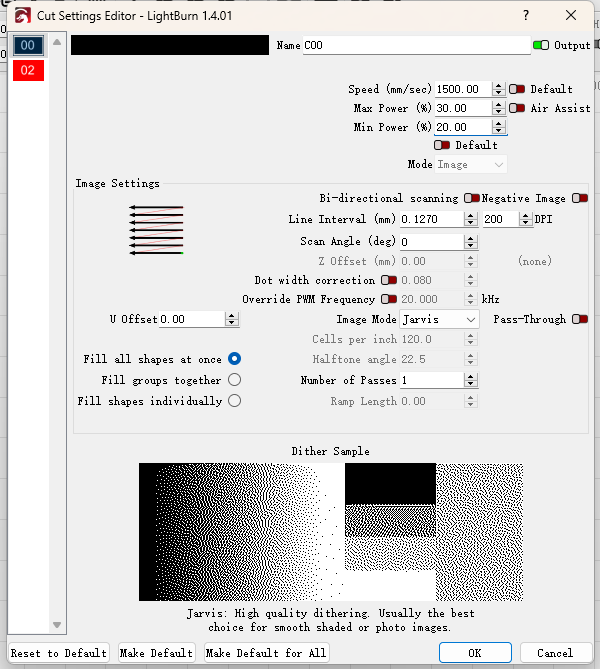

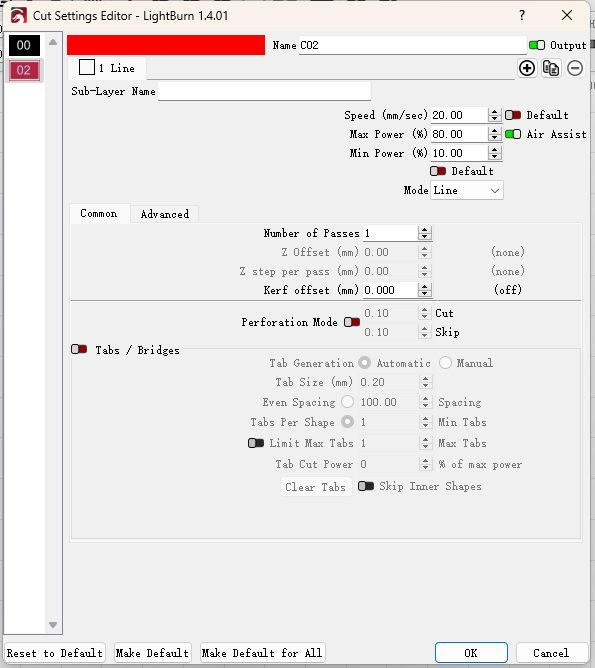

Step 1: Choose the Appropriate Parameters

Confirm the correct speed and power settings based on the specific material and thickness.

Decide between unidirectional or bidirectional fill; unidirectional often yields better results but takes longer. Here, unidirectional fill is selected.

Generally, set the DPI to 300. The higher the DPI, the more lines and the deeper the engraving.

Since this is an image engraving, select the appropriate image mode. Here, Jarvis mode is chosen.

In the advanced options, ensure the slope value is set to “0.”

Step 2: Focus

Step 3: Send the file

2、Machine Operation

Step 1: Focus the laser head

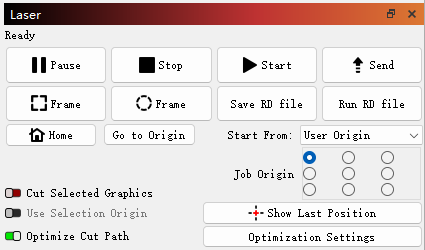

Step 2: Select the file and confirm

Step 3: Sample positioning confirmation

Move the laser head to the center position and check the distance from the top, bottom, left, and right of the pattern, ensuring it is centered as much as possible.

After determining the correct position, click the positioning button to confirm the starting point.

Run the frame to see if the engraving range fits entirely on the sample surface.

Once the position is set and all settings like focus are correct, click the start button.

Step 4: Monitor the process

You can cut the board beforehand and tape around it to prevent the wood from warping.

Monitor the engraving process to prevent any unexpected incidents. Do not leave the machine unattended while it is running.

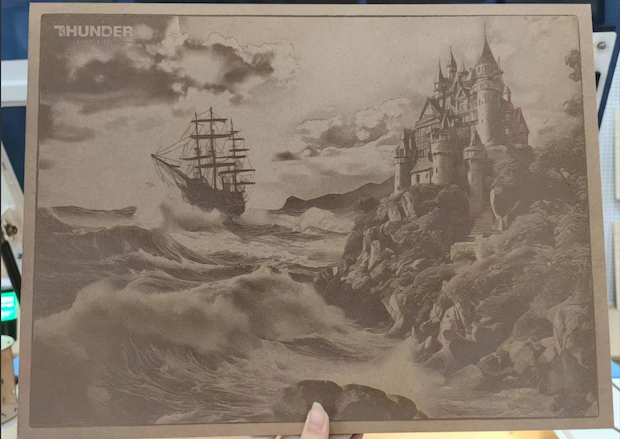

Step 5: Engraving finished

.png) International

International

United States

United States

Brasil

Brasil

Canada

Canada

Costa Rica

Costa Rica

Česká

Česká

Ελλάδα

Ελλάδα

Polska

Polska

Ireland

Ireland

Portugal

Portugal

Lietuva

Lietuva

Россия

Россия Deutschland

Deutschland

Britain

Britain

Україна

Україна

France

France

Sverige

Sverige

Italia

Italia

Norway

Norway

Denmark

Denmark

Romania

Romania

한국

한국

中国

中国

ประเทศไทย

ประเทศไทย

中国香港

中国香港

Israel

Israel

中國臺灣

中國臺灣

India

India

پاکستان

پاکستان

پශ්රී ලංකා

پශ්රී ලංකා

ジャパン

ジャパン

Australia

Australia

New Zealand

New Zealand

South Africa

South Africa