- Author: Cathy

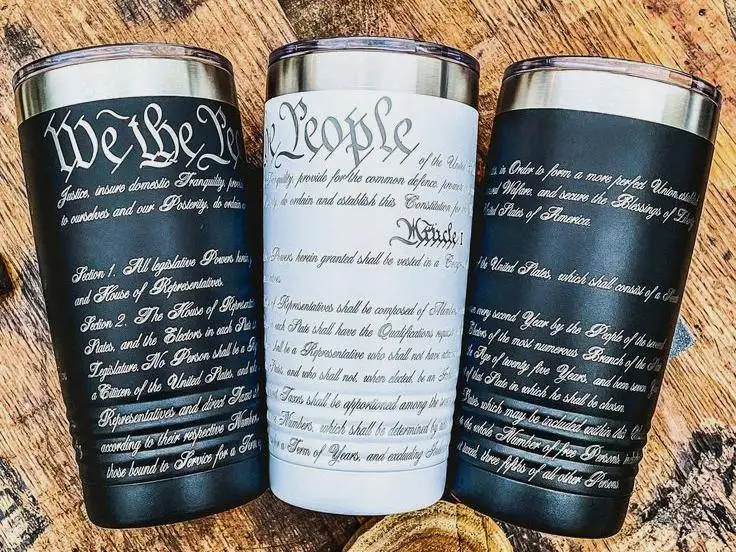

Laser engravers are excellent for customizing tumblers with unique designs, logos, and personalization. Using the power of laser beams, these laser engraver for tumblers creates precise and intricate engravings. Popular Tumbler products include gifts, promotions, events, and branding items.

Laser engraver for tumblers offers precise control over laser power, speed, and depth. As a result, it can create intricate designs and text on various laserable materials used for tumblers. Stainless steel, glass, and plastics are the three most popular materials used in tumblers. You can laser engrave names, logos, monograms, quotas, and custom designs on tumblers. Laser engraving enhances the visual appearance and value of the tumblers.

1. What Do You Need to Laser Engrave Tumblers?

Laser engraving tumblers requires more than just the right machine—it’s a combination of proper tools, compatible materials, and thoughtful preparation. Whether you’re customizing stainless steel drinkware or powder-coated tumblers, several key components ensure precise, high-quality results. From choosing the right laser engraver to preparing your design and setting up the workspace, here’s everything you’ll need to get started:

1.1. Laser Engraver

1.2. Rotary Attachment

1.3. Tumbler Material

1.4. Design Software

1.5. Proper Settings

Why is Laser Engraved Tumbler So Popular?

Laser engraved tumblers are popular due to their personalization potential and durability. They offer a unique, permanent way to customize drinkware with names, logos, or designs. The specific applications of tumblers may vary based on the particular types. Glass and plastic tumblers are famous for serving drinks in homes, restaurants, and bards. Stainless steel tumblers are ideal for outdoor activities such as camping, hiking, or picnics. Ceramic tumblers are often used for decorations and collectable items.

The precision of laser engraving allows for intricate details, while the process doesn’t compromise the tumbler’s functionality or dishwasher safety. This combination of practicality and personalization makes them appealing for gifts, promotions, and personal use.

2. What Laser Engraved Tumblers Can You Create?

Stainless Steel

Coated Metal

Glass

- Customized tumblers with names or initials

- Logo or brand-engraved tumblers

- Sport-themed tumblers

- Custom artwork or designs

- Special occasion and holiday theme tumblers

3. What to Consider When Choosing a Tumbler Laser Engraver?

3.1. Laser Types and Power

The type of laser determines the materials you can process. CO2 lasers can generally work with a wide range of non-metal materials such as wood and coated metals, while fiber lasers are designed for processing metal materials.

Laser power is a crucial factor to consider. It determines the depth and speed of the engraving. Therefore, tumblers made of materials like stainless steel or glass require higher laser power. On the other hand, materials like plastic or ceramics may require lower power.

3.2. Working Area

3.3. Rotary Attachment Compatibility

3.4. Software Compatibility

You should ensure software compatibility with your design requirements. Look for machines that offer user-friendly software like LIGHTBURN with design compatibilities. The software should also be compatible with popular file formats.

3.5. Durability and Reliability

3.6. Budget

4. How to Choose a Tumbler for Laser Engraving?

4.1. Yeti Tumbler

- Material and Quality

- Laser Engraving Results

- Market Appeal

4.2. Stanley Tumbler

- Material and Quality

- Laser Engraving Results

- Market Appeal

4.3. Summary

Yeti: If you prioritize the visual impact of the engraving, especially the contrast and clarity, Yeti tumblers might be the better choice. Their surface coating is well-suited for laser engraving, and the brand’s high recognition can attract consumers.

Stanley: If your target market leans more towards outdoor or workwear styles, Stanley is an excellent option. Their durability and classic design are significant advantages.

Ultimately, the choice depends on your customer preferences and brand affinity. If possible, consider purchasing a small number of both brands to test engravings and determine which one meets your expectations better.

5. How to Laser Engrave a Tumbler with a Laser Engraver for Tumblers?

Step #1: Preparation

Step #2: Mounting

Step #3: Setup

This step consists of two parts. One is to prepare the engraving design, and the other is to set up the laser machine. Using the recommended laser software, you can customize your design. You can also choose the appropriate laser settings in this software. However, the laser settings will depend on the material you use for tumblers. In this case, pay attention to the specific material settings.

The second part involves setting up the laser device. You can adjust the focus of the laser beam based on different heights. It would be best if you checked the lens before engraving. Ensure that the lens is clean and free of contaminants. Finally, ensure the proper safety of the operator.

Step #4: Engraving

Step #5: Finishing

How to Clean Tumbler After Laser Engraving?

- Remove Loose Debris:

Gently wipe off any dust or residue with a soft, dry cloth or microfiber towel. - Use Mild Soap and Water:

Fill a bowl with warm water and add a few drops of mild dish soap. Dampen a soft cloth or sponge and gently wipe the engraved area. - Avoid Scratching:

If there’s any stubborn residue, avoid using abrasive materials that could scratch the surface. Instead, use a soft brush or a non-abrasive scrub pad. - Use Rubbing Alcohol(Optional):

For tougher residue, rubbing alcohol on a soft cloth can help remove any leftover marks from the engraving process.

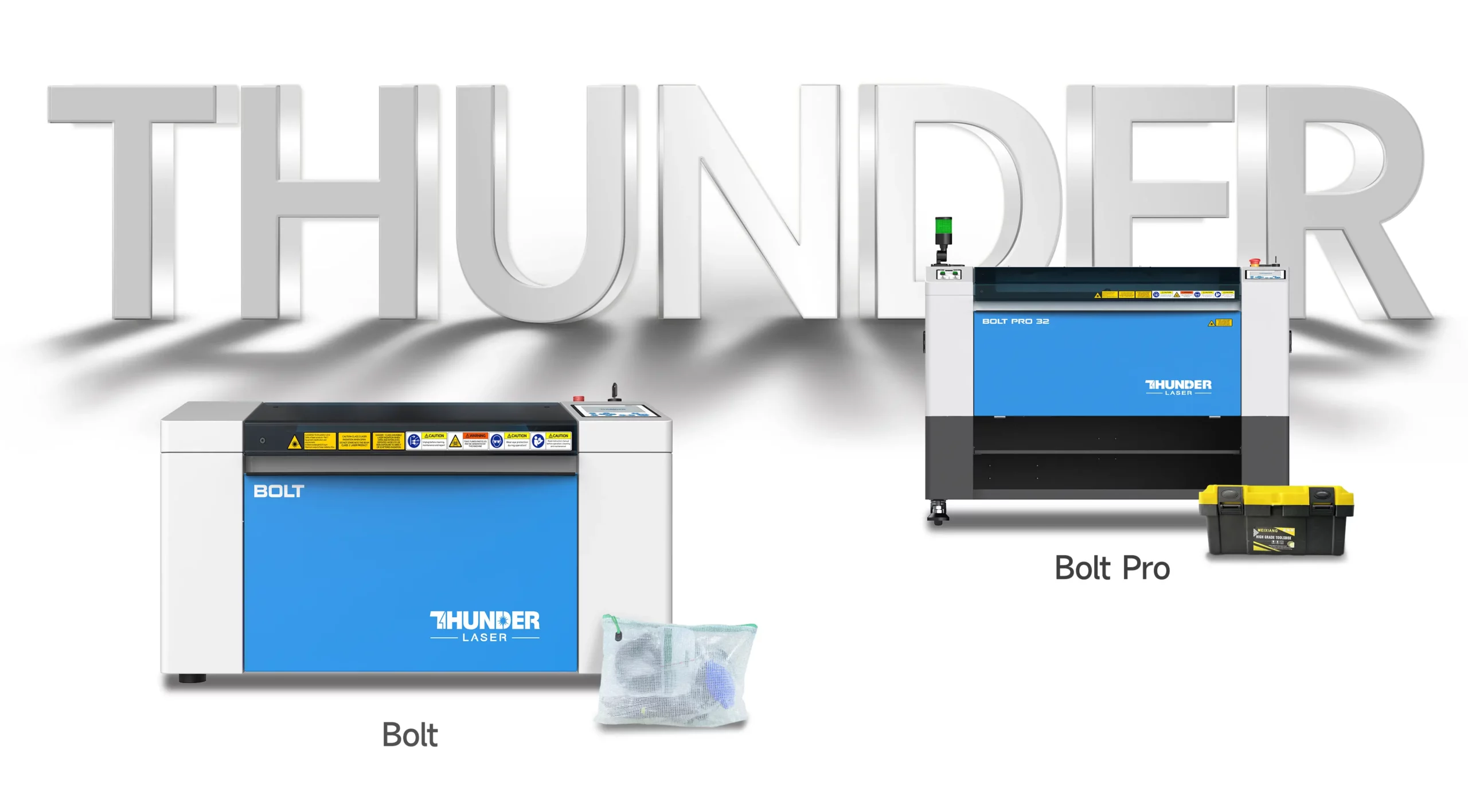

6. Your Best Choice: Thunder Laser Tumbler Engraver

Among them, the Bolt series offers the highest engraving precision. It delivers powerful laser performance, with options for desktop or large-scale floor models, and compatibility with a rotary device. Equipped with a 30W or 55W RF laser tube, it is perfect for engraving tumblers made of stainless steel, plastic, glass, ceramics, and coated metals.

The Bolt series is a versatile laser machine suitable for different types of tumblers, and its various sizes offer flexibility for creations at home or in the studio. No matter the model, it ensures precise and consistent engraving.

If you’re looking to produce a larger volume of tumblers at a great value, the Nova series is your best option, with its large working area. For metal engraving, the Aurora series specializes in metal tumblers, making it the perfect choice for engraving metal cups.

Conclusion

Laser engraving tumblers is more than just customization—it’s a way to unleash creativity and add value to everyday items. Whether you’re crafting personalized gifts, promotional merchandise, or standout drinkware for special events, a quality tumbler laser engraver can transform your ideas into lasting impressions.

With the right laser machine, especially a reliable and precise machine like the Thunder Laser Bolt series, you can achieve professional results on a wide range of tumbler materials. Start your engraving journey today and turn ordinary tumblers into extraordinary works of art.

FAQs About Laser Engraver for Tumblers

Q1. How long does it take to engrave a tumbler?

It depends on the complexity of the design and the machine’s speed, but typically takes 3–10 minutes per tumbler.

Q2. How do I clean the tumbler after engraving?

After engraving, use a soft cloth to wipe the tumbler. If necessary, you can clean it with mild soap and water, but avoid scrubbing the engraved area to preserve the design.

Q3. Can laser engraving be used for color filling on tumblers?

While most lasers don’t fill with color, you can apply paint or ink to the engraved area to enhance the contrast, but this requires extra work after LASER engraving.

Q4. Can I laser engrave multiple tumblers at the same time?

Yes, with a rotary axis and proper jig setup, you can engrave tumblers in succession for batch processing, improving efficiency for small business production.

Q5. What type of maintenance does a laser machine require for tumbler engraving?

Regular cleaning of the lens, checking alignment, and ensuring the rotary attachment functions properly are key to consistent tumbler engraving results.

- Tags

#tumbler, #laser engraving, #tumbler engraving, #laser engraving tumbler, #laser engraved tumbler, #tumbler laser engraver, #tumbler for laser engraving, #tumbler laser engraving machine, #co2 laser, #coated metal

.png) International

International

United States

United States

Brasil

Brasil

Canada

Canada

Costa Rica

Costa Rica

Mexico

Mexico

Česká

Česká

Romania

Romania

Polska

Polska

Ireland

Ireland

Portugal

Portugal

Lietuva

Lietuva

Россия

Россия Deutschland

Deutschland

Britain

Britain

Україна

Україна

France

France

Sverige

Sverige

Italia

Italia

Norway

Norway

Denmark

Denmark

Ελλάδα

Ελλάδα

한국

한국

中国

中国

ประเทศไทย

ประเทศไทย

中国香港

中国香港

Israel

Israel

中國臺灣

中國臺灣

India

India

پاکستان

پاکستان

پශ්රී ලංකා

پශ්රී ලංකා

ジャパン

ジャパン

Australia

Australia

New Zealand

New Zealand

South Africa

South Africa