Precise Laser Cutting and Engraving Fabric

- Home

- >

- Laser engraver materials

- >

- Precise Laser Cutting and Engraving Fabric

Outline

Can you laser engrave fabric?

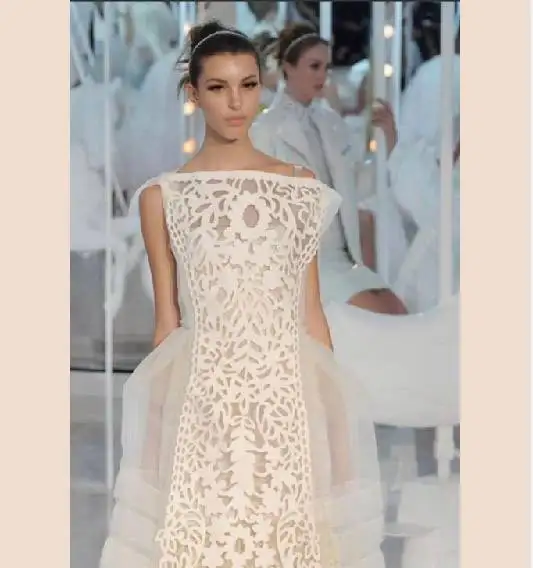

Yes, you can laser cut and engrave fabric and textiles using a fabric laser cutting machine, making it a top choice for achieving precise cuts and detailed engravings. Laser is widely favored in industries like fashion, interior design, and crafts, thanks to its ability to produce intricate designs with clean edges and minimal fraying or distortion.

Whether you’re customizing apparel, creating stunning home décor, or exploring artistic projects, laser cutting and engraving fabric opens up endless creative possibilities. Discover how lasers can transform your designs with us!

What are the adavantages of laser fabric?

Unlike manual or die cutting, laser cutting provides unmatched precision and detail, allowing for intricate patterns and clean edges. Laser cutting may not be suitable for all fabric types and might require higher initial investment compared to manual tools. However, its versatility and precision make it a preferred choice for modern textile design and production.

Here are some main advantages of laser engraving and cutting fabric.

- Precision and accuracy

- Customizability

- Non-contact processing

- Compatibility with different fabrics

- Eco-friendly

- Speed and efficiency

What is the best laser to cut fabric?

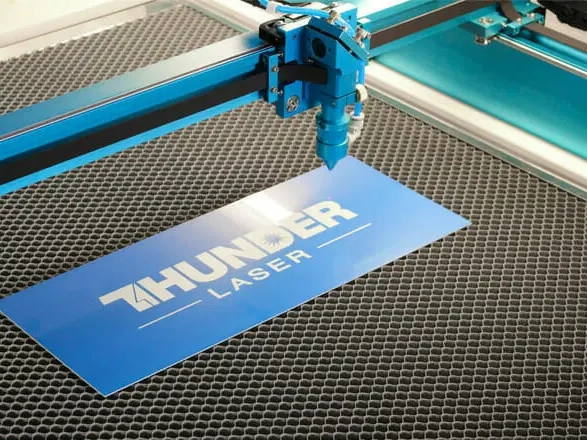

The CO2 laser is the best choice for cutting fabric and textiles, offering exceptional precision and clean results. It excels in creating intricate designs without causing fraying or distortion, making it ideal for both delicate fabrics like silk and more durable options such as denim or polyester. The heat generated by the laser seals the edges of synthetic materials during the cutting process, preventing fraying and eliminating the need for additional finishing.

In comparison, diode lasers lack the necessary power and speed for clean cuts, and fiber lasers are designed for metals rather than fabrics. For anyone working with fabric, whether for creative or professional purposes, a CO2 laser like the Thunder Laser Nova or Bolt series delivers the precision, speed, and reliability needed for high-quality results.

What type of fabric can you laser cut and engrave?

1. Denim

2. Velvet

3. Felt

4. Cotton

5. Silk

Important Note:

What can you create: Enjoy the magic with laser fabric!

Laser cutting fabric

Laser engraving fabric

Choosing the best laser cutter for fabric

Pick THUNDER LASER fabric cutter!

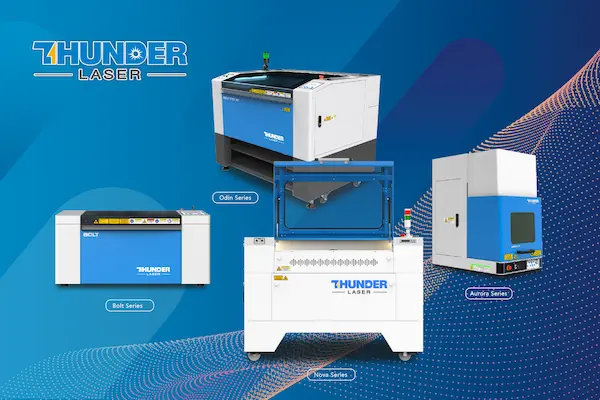

Thunder Laser fabric cutters are the perfect solution for laser engraving fabric. The Nova and Bolt series each have unique advantages, both capable of cutting or engraving fabric perfectly with clean edges and no fraying or waste.

The Nova series has a maximum laser power of 130W and a larger working platform (including a pass-through door). With high power and speed, it allows for the completion of larger projects with ease, and it’s ideal for mass production, increasing the productivity of your laser workshop.

The Bolt series focuses on precision, featuring RF laser tubes for precise laser control. You can choose between desktop and floor-standing Thunder Bolt Pro models. The desktop version allows for small fabric item customization at home, while the larger and more professional Bolt Pro enables enterprise-level precision in laser cutting and engraving.

Choose the fabric laser cutting machine that best suits your needs! We are here to assist you with any questions or concerns.

Laser settings for fabric and textiles

We provide the fabric laser processing parameters for the Thunder Laser Bolt – RF 30w as a reference! Our parameters have undergone rigorous testing to ensure the best results for your projects. However, due to variations in machines or models, it’s always recommended to conduct small-scale tests on specific fabrics and textiles beforehand.

| Material | Thickness | Process | Speed(mm/s) | Min Power(%) | Max Power(%) | Blow Type | DPI |

|---|---|---|---|---|---|---|---|

| Cotton fabric | / | Engraving | 1000 | 40 | 40 | low | 350 |

| 1mm | Cutting | 160 | 10 | 90 | high | 1.5'' | |

| 3mm | Cutting | 140 | 10 | 90 | high | 1.5'' | |

| Denim | / | Engraving | 1000 | 20 | 20 | low | 350 |

| 1mm | Cutting | 150 | 10 | 90 | high | 1.5'' |

For more laser cutting and laser engraving fabric settings, please click here.

Tips and tricks for laser engraving and cutting fabric

1. What designs work best for fabric engraving?

2. How to address fabric instability during laser processing?

If your textile laser cutting or engraving process results in issues such as shape distortion, uneven cuts, fraying edges, or fiber damage, it indicates that the fabric may be experiencing instability. You can take several measures to address it:

Increase fabric moisture: Slightly dampening the fabric before processing can reduce the risk of fibers breaking or being burned, as moisture helps dissipate heat more evenly.

Adjust laser focus or design settings: Using a defocused beam or adjusting the grayscale of the design can help maintain fabric integrity. This method applies less direct heat, preventing damage to delicate areas.

Refine your technique: Consider using lower power and slower speeds or implementing additional supports, such as a backing material, to stabilize the fabric during processing.

3. How to store laser fabrics?

Ideal storage conditions: Store fabrics in a well-ventilated, dry environment at room temperature. Avoid exposing them directly to sunlight, heat sources, or humidity, and consider using anti-mold and anti-moth agents.

Use protective bags:It’s best to store fabrics in sealed bags to protect them from dust and pests.

Care for wool fabrics: For wool fabrics, periodically open storage boxes or cabinets to ensure proper ventilation and maintain dryness.

Prevent mildew in humid seasons: During high-temperature and humid seasons, wool fabrics should be aired out a few times to prevent mildew.

- Tags

#fabric, #textile, #laser, #laser engraving, #laser cutting, #laser cut fabric, #laser cutting textiles, #laser engraving fabric, #laser cutting fabric, #co2 laser, #laser machine, #laser cutter, #laser cutter for fabric

.png) International

International

United States

United States

Brasil

Brasil

Canada

Canada

Costa Rica

Costa Rica

Česká

Česká

Ελλάδα

Ελλάδα

Polska

Polska

Ireland

Ireland

Portugal

Portugal

Lietuva

Lietuva

Россия

Россия Deutschland

Deutschland

Britain

Britain

Україна

Україна

France

France

Sverige

Sverige

Italia

Italia

Norway

Norway

Denmark

Denmark

Romania

Romania

한국

한국

中国

中国

ประเทศไทย

ประเทศไทย

中国香港

中国香港

Israel

Israel

中國臺灣

中國臺灣

India

India

پاکستان

پاکستان

پශ්රී ලංකා

پශ්රී ලංකා

ジャパン

ジャパン

Australia

Australia

New Zealand

New Zealand

South Africa

South Africa