Laser Cut Foam: Unlocking Your Creativity

- Home

- >

- Laser engraver materials

- >

- Laser Cut Foam: Unlocking Your Creativity with Foam

Outline

Can you laser cut foam?

Laser foam has become the go-to solution for precision and innovation across multiple industries. EVA foam, with its remarkable shock-absorbing, sound-insulating, and thermal-insulating properties, has transformed the world of sports equipment, household appliances, fitness gear, shoes, and crafts.

The fusion of these two materials unleashes a world of opportunities, making them an ideal choice for sports equipment, household appliances, printing, fitness gear, shoes, and crafts. Laser machine is the best tool to laser cut foam.

Laser cutting foam is the secret sauce that elevates EVA foam to a whole new level of creativity and precision. Its accuracy and versatility make it the perfect tool to shape and cut this soft yet sturdy foam. The laser cut foam application extends far and wide, encompassing multiple industries, leading to a burgeoning market for laser sales.

What types of foam are suitable for laser cutting?

1. Polyethylene foam (PE foam)

2. EVA foam

3. Polyurethane foam (PU foam)

4. Polystyrene foam (Styrofoam)

Laser cutting foam projects and ideas

- Advertising signage

- Holiday decorations

- Packaging inserts

Explore our sample library for more exciting laser engraving and cutting ideas, along with free files!

Eva foam or polyurethane foam, which one is better?

Now, let’s tackle the question of whether to choose EVA foam or Polyurethane foam for your laser-cut foam projects. While these materials may appear similar, they serve different applications in the world of laser workmanship.

EVA foam, lightweight, flexible, and non-toxic, is the ideal choice for creative projects like crafts, role-play props, and packaging. On the other hand, Polyurethane foam, known for its durability and wear resistance, is more suited for industrial and commercial applications such as insulation, protective packaging, and even house heating solutions.

When it comes to laser cutting foam, EVA foam has more advantages than Polyurethane Foam. It requires lower power settings, resulting in cleaner cuts and reduced heat accumulation compared to Polyurethane foam.

Where to buy?

-

1. Uline

A popular choice for many, Uline offers a variety of laser-cut foam sheets and materials to cater to your needs. Explore their selection here

-

2. Polymershapes

With 80 stores across the United States, Polymershapes provides a wide range of foamboard and paperboard options, ideal for laser-cut foam projects. Check out their offerings here

-

3. Foam factory

Choosing a perfect laser foam cutter for you!

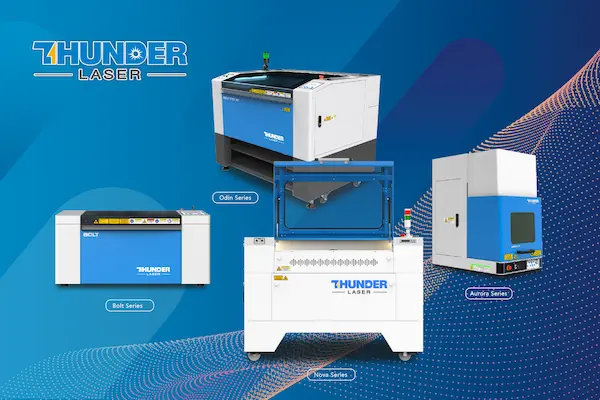

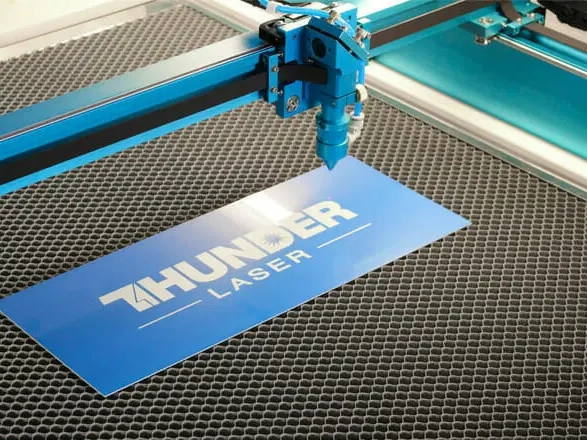

To choose the perfect laser model for your foam cutting projects, consider the Thunder Laser Nova and Bolt series. CO2 laser machines are highly effective for cutting foam boards, and Thunder Laser’s models deliver clean and precise results on foam materials.

The Thunder Nova excels with its higher laser power and larger work platform, making it a powerhouse for demanding projects. It’s an excellent choice for cutting larger foam boards or handling bulk tasks efficiently, especially if you have the space to accommodate its robust design.

The Thunder Bolt, on the other hand, is ideal for creative laser work at home. Its compact desktop size offers high engraving precision and can handle foam cutting tasks with ease. For even greater capabilities, you can upgrade to the Thunder Bolt Pro, an enterprise-level machine designed to help grow your laser business.

Your choice depends on your specific needs! Check out how customers use the Thunder Nova for foam board laser cutting. With Nova’s camera positioning system and LightBurn software, creating custom foam liners becomes simple and efficient.

Eva foam laser cutting settings

Now, let’s delve into the specifics of laser cutting EVA foam. Keep in mind that the cutting outcome can vary based on the foam’s origin, batch, and production method. Here are some general parameters to get you started, but you may need to fine-tune them for your specific laser-cut foam project.

| Process | Thickness | Speed(mm/s) | Min Power(%) | Max Power(%) | Blow Type | DPI |

|---|---|---|---|---|---|---|

| Engraving | / | 500 | 13 | 13 | low | 300 |

| Cutting | 10mm | 45 | 10 | 90 | high | 2" |

| 20mm | 22 | 10 | 90 | high | 4" | |

| 30mm | 7 | 10 | 90 | high | 4" |

Check out our knowledge base for more material settings!

Tips and tricks for laser cut foam

1. How to maintain a clean cut when cutting foam?

2. How do I laser cut foam thicker than 1 inch?

To cut foam thicker than 1 inch, you’ll need to use a 4-inch lens instead of the standard 2-inch lens to get better results. The longer focal length of the 4-inch lens allows the laser beam to maintain focus over the deeper material, ensuring a clean and precise cut. Using a 2-inch lens for thicker foam may result in scalloped or uneven edges due to the limited focal range.

3. What type of foam works best for laser cutting?

4. How can you process foam without causing it to melt?

Excessive heat can cause foam materials to melt. To avoid this, reduce the laser’s power and speed while performing multiple passes to achieve a deeper engraving or cleaner cut. You can also utilize the dot mode to minimize heat exposure on the material. Additionally, maximize the effectiveness of air assist to keep the cutting area cool.

- Tags

.png) International

International

United States

United States

Brasil

Brasil

Canada

Canada

Costa Rica

Costa Rica

Česká

Česká

Ελλάδα

Ελλάδα

Polska

Polska

Ireland

Ireland

Portugal

Portugal

Lietuva

Lietuva

Россия

Россия Deutschland

Deutschland

Britain

Britain

Україна

Україна

France

France

Sverige

Sverige

Italia

Italia

Norway

Norway

Denmark

Denmark

Romania

Romania

한국

한국

中国

中国

ประเทศไทย

ประเทศไทย

中国香港

中国香港

Israel

Israel

中國臺灣

中國臺灣

India

India

پاکستان

پاکستان

پශ්රී ලංකා

پශ්රී ලංකා

ジャパン

ジャパン

Australia

Australia

New Zealand

New Zealand

South Africa

South Africa