Can You Laser Engrave Glass?

- Home

- >

- Laser engraver materials

- >

- Can You Laser Engrave Glass?

Outline

Can laser engrave or cut glass?

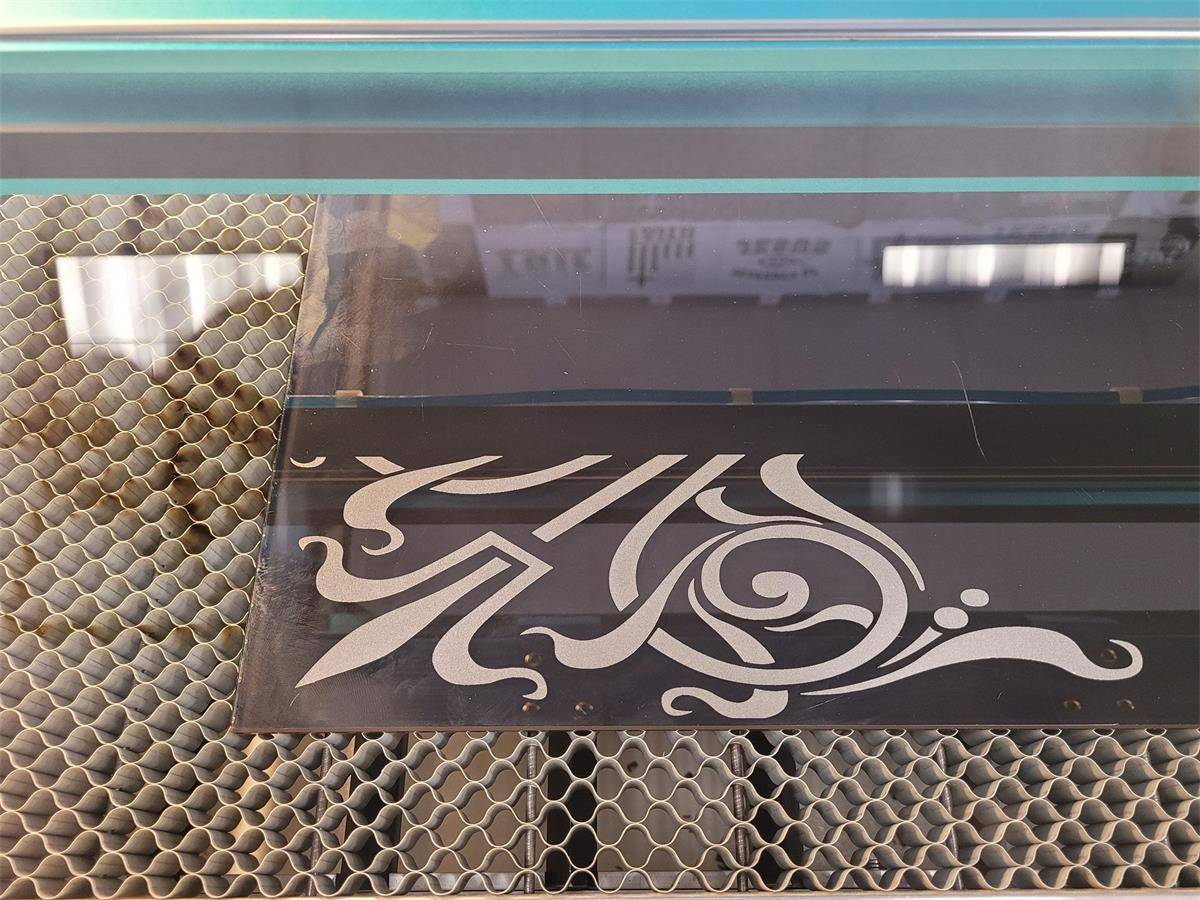

Yes, a laser can engrave glass but cannot cut it. Laser engraving on glass involves using a laser beam to etch the surface, creating designs or text with precision. However, cutting through glass requires a different process, as lasers aren’t powerful enough to penetrate the material cleanly without causing cracks or shattering.

Laser engraver for glass like UV laser is commonly used for glass marking, providing accurate and detailed results.CO2 lasers can also engrave glass, offering faster speed but with lower engraving quality compared to UV lasers. they are a popular choice due to their lower cost and wider material compatibility.

What is the difference between glass etching and glass engraving?

Glass etching and glass engraving are distinct techniques for decorating glass. Glass etching typically involves using an etching cream or acid to create a frosted, matte effect on the glass, resulting in a soft, translucent design. It is often used for larger areas and simpler patterns. In contrast, glass engraving uses tools like lasers or rotary devices with diamond bits to remove material and create detailed, high-contrast designs directly on the glass surface. Engraving produces clear, sharp lines and is ideal for intricate designs.

In a word, while etching offers a subtle, textured look with etching cream or acid, engraving provides precise and detailed marks by lasers.

Glass laser engraving ideas

- Photo engraving

- Glass cups and bottles

Use a rotary device to engrave designs or text on glasses, turning them into personalized drinkware.

- LED light

Which glass is the best for laser engraving?

What laser is best for glass engraving?

The best laser for glass engraving is typically a UV laser due to its ability to create precise and fine details on the glass surface. UV lasers have a shorter wavelength, which allows them to engrave with greater accuracy and less heat, resulting in clean and intricate glass laser marking designs. CO2 lasers are used for glass laser engraving as well. While it is faster and more commonly available, they do not achieve the same level of fine detail as UV lasers, and the results may appear less sharp.

Fiber lasers, on the other hand, are generally ineffective for glass engraving because glass doesn’t absorb its wavelength well. To attempt engraving with a fiber laser, auxiliary methods such as coating the glass with a special substance might be necessary, but even then, the results are suboptimal.

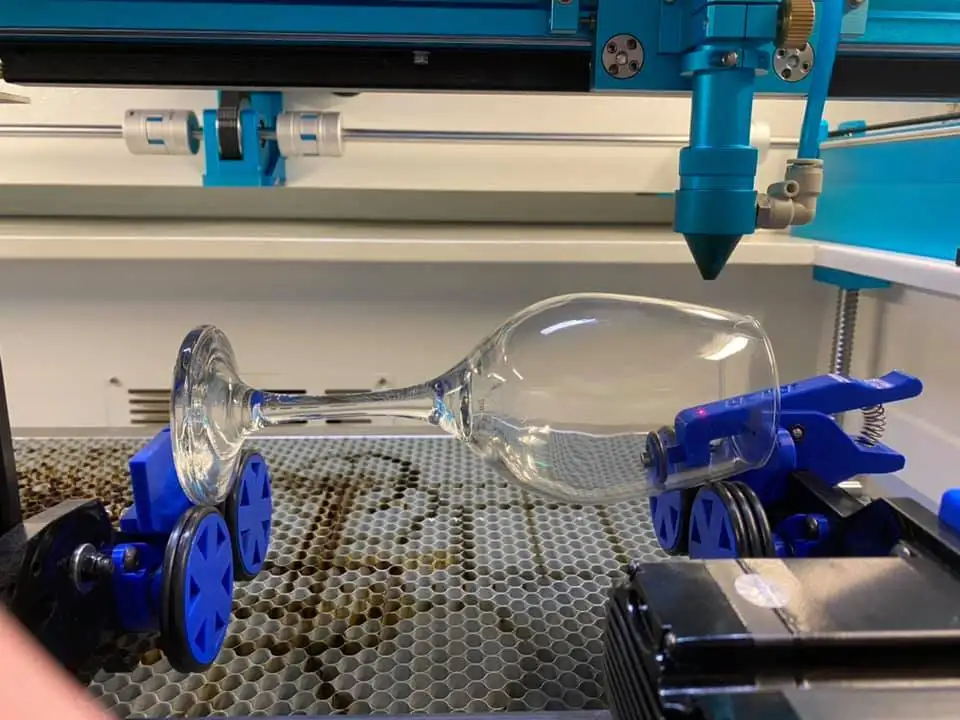

How to laser engrave glass using a rotary device?

Key considerations

Glass Thickness: Ensure that the glass is thick enough to withstand engraving without cracking.

Rotary Speed: Adjust the rotary device speed for smooth rotation based on the glass size and design complexity.

Focus Adjustments: When engraving on curved surfaces, adjusting the laser focus is critical to maintain engraving quality.

1. Prepare the glass

2. Setup the rotary device

3. Position the glass

4. Set the focus

Set the laser focus to match the highest point of the glass.

5. Adjust laser parameters

6. Test the design

7. Post-engraving care

Recommended settings for laser engraving glass

| Laser source | Speed(mm/s) | Pulse Width(μs) | Frequency(KHz) | Power(%) | Air pressure value | DPI |

|---|---|---|---|---|---|---|

| UV lasers - 5w | 500-250 | 1 | 50 | / | / | 0.02 |

| CO2 lasers-80w glass tube | 500 | / | / | Min: 10; Max: 80 | 0.1 | 300 |

Tips and tricks for laser engraving on glass

How to color engraved glass?

1. Filling with Paint or enamel

2. Colored glass coatings

3. Engraving with paint backing

How do you engrave glass without breaking it?

When the laser beam touches the glass surface in the laser glass etching machine, it heats up and the glass molecules scatter. Glass must be cool down first to avoid the big heat especially when you want to laser etch glass with high quality. When the potholes generated by heating become larger and larger, the final carving effect of glass will be as bad as rotten mud if it not be cool.

Because the glass does not have a fixed melting point, we need to disperse heat to dissipate or reduce the heat reaching the glass, so that the glasses can avoid cracking. We can use the following four materials to avoid glass breakage.

- Use laser masking tape

- Wet tissue (should be laid flat without bubbles, otherwise there may be problems with the carving at the bubbles)

- Wet paper

- Detergent

How to clean engraved glass?

- Tags

#glass engraving, #glass laser engraving, #glass etching, #how to laser engrave glass, #can you laser engrave glass, #glass image engraving, #co2 laser, #uv laser

.png) International

International

United States

United States

Brasil

Brasil

Canada

Canada

Costa Rica

Costa Rica

Česká

Česká

Ελλάδα

Ελλάδα

Polska

Polska

Ireland

Ireland

Portugal

Portugal

Lietuva

Lietuva

Россия

Россия Deutschland

Deutschland

Britain

Britain

Україна

Україна

France

France

Sverige

Sverige

Italia

Italia

Norway

Norway

Denmark

Denmark

Romania

Romania

한국

한국

中国

中国

ประเทศไทย

ประเทศไทย

中国香港

中国香港

Israel

Israel

中國臺灣

中國臺灣

India

India

پاکستان

پاکستان

پශ්රී ලංකා

پශ්රී ලංකා

ジャパン

ジャパン

Australia

Australia

New Zealand

New Zealand

South Africa

South Africa