Laser Cut Grip Tape: A Comprehensive Guide

- Home

- >

- Laser engraver materials

- >

- Laser Cut Grip Tape: A Comprehensive Guide

Outline

Can you laser cut grip tape?

Yes, laser cutting grip tape is indeed possible, offering remarkable speed and precision that transforms traditional processing methods. While common tools like vinyl cutters and manual cutting blades have been standard, laser cutting brings unprecedented accuracy and efficiency to grip tape processing.

However, grip tape laser cutting isn’t without challenges – the material’s abrasive surface and adhesive backing can potentially generate harmful fumes, risk equipment damage. Despite these considerations, laser cutting opens up exciting possibilities for intricate designs and custom patterns that were previously difficult or impossible to achieve. By understanding and mitigating the potential risks with this article, you can unlock a new world of creative potential in grip tape fabrication.

Can you laser engrave grip tape?

Advantages of laser cut grip tape

- No wear and tear

- High precision

- Non-contact cutting

- Clean and neat edges

- Super efficient

- Mass production

Grip tape is essentially a hard paper material with a tough, non-slip layer that defines its primary function. This inherent hardness traditionally makes it challenging to cut using conventional methods.

While traditional grip tape cutting relied on manual tools, these approaches quickly encountered significant limitations due to the abrasive surface embedded with high-hardness particles, which caused rapid tool wear and increased cutting costs.

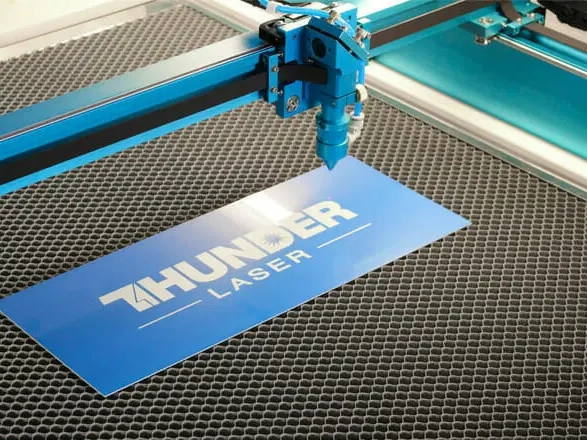

Laser cutting revolutionizes this process by offering a completely different approach. By focusing a laser beam onto the product surface and heating the material, laser cutters can precisely cut grip tape without physical contact. This non-contact cutting method not only reduces tool wear to practically zero but also dramatically improves cutting precision.

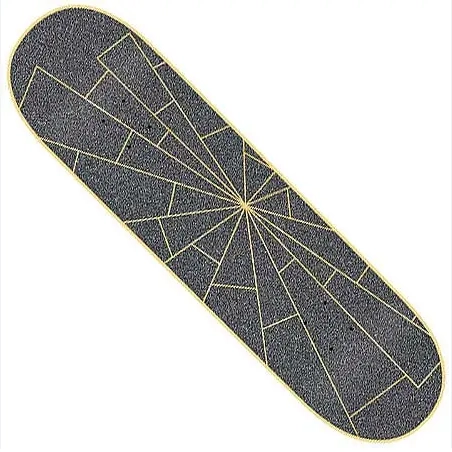

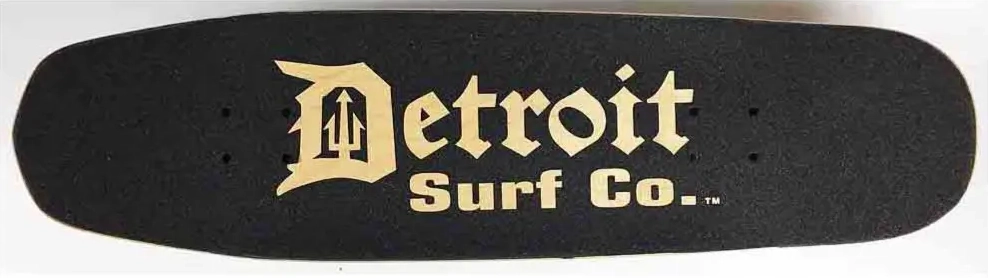

Creative laser cut grip tape designs

1. Customized text skateboards

2. Cool image skateboards

3. Festival ornaments

Learn more laser engraving and cutting designs in our sample library!

How to laser cut grip tape?

1. Prepare the grip tape

2. Secure the material

3. Adjust laser settings

Learn more: Laser settings for different materials

4. Optimize ventilation

5. Cutting process

6. Clean the edges

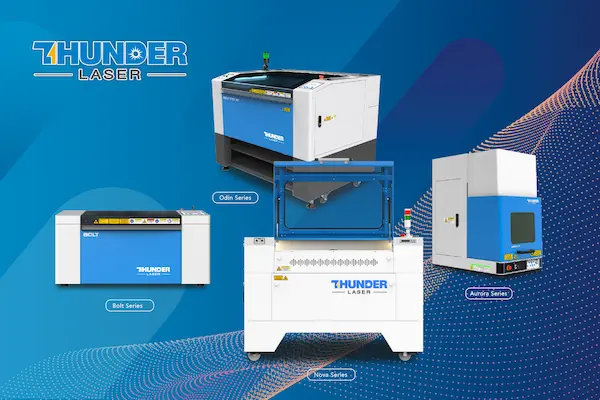

Choosing the right laser cutter for your laser grip tape project

The Nova laser cutter is the best choice for cutting grip tape. As a CNC CO2 laser cutting machine, it can process a wide range of non-metal materials, making it a popular choice for most laser cutting applications. It also has unique advantages when it comes to cutting grip tape.

Grip tape is most commonly used as an anti-slip material, with skateboards being the most widespread application. Skateboards are large and require a machine with a spacious work area, not a typical home-use laser machine. Nova, with its large size, offers a wide working area and pass-through doors, making it ideal for handling larger items.

In addition to its size, the Nova also offers higher power, fast cutting speeds, and high precision, allowing for efficient and high-quality laser cutting of grip tape. It is the perfect choice for your grip tape projects and can help you run your laser business effectively.

If you mainly want to process small-sized grip tape, the Bolt series is also a great choice for you! Our flagship Thunder Bolt Desktop Engraver uses an RF tube CO2 laser, offering high engraving precision and versatility for various non-metal materials. Meanwhile, the floor-standing Thunder Bolt Pro is larger and more professional, capable of handling larger materials while providing enterprise-level processing.

Tips and tricks for laser cut grip tape

1. How prevent grip tape warping during laser cutting?

2. How to manage the adhesive side of the grip tape?

When cutting sand tape, it is important to maintain proper ventilation to eliminate smoke from the working area. Adequate ventilation prevents the accumulation of potentially harmful gases and minimizes process-related odors, thereby helping to maintain a safe working environment.

3. How to stay safe when laser cutting grip tape?

1. Ensure proper ventilation to eliminate smoke from the work area. Adequate airflow prevents the buildup of potentially harmful gases and minimizes odors associated with the process, helping to maintain a safe working environment.

2. Always wear personal protective equipment such as gloves and safety goggles. Cutting grip tape can produce sparks when the laser interacts with the abrasive particles, so taking precautions is essential to avoid injury.

4. How to store laser cut grip tape?

1. Store the grip tape in a well-ventilated, dry environment at room temperature. Avoid exposing it directly to sunlight, heat sources, or moisture to prevent damage.

2. It’s best to store grip tape rolled up rather than stacked. Stacking can create creases that are difficult to fix and may affect its usability.

- Tags

.png) International

International

United States

United States

Brasil

Brasil

Canada

Canada

Costa Rica

Costa Rica

Mexico

Mexico

Česká

Česká

Romania

Romania

Polska

Polska

Ireland

Ireland

Portugal

Portugal

Lietuva

Lietuva

Россия

Россия Deutschland

Deutschland

Britain

Britain

Україна

Україна

France

France

Sverige

Sverige

Italia

Italia

Norway

Norway

Denmark

Denmark

Ελλάδα

Ελλάδα

한국

한국

中国

中国

ประเทศไทย

ประเทศไทย

中国香港

中国香港

Israel

Israel

中國臺灣

中國臺灣

India

India

پاکستان

پاکستان

پශ්රී ලංකා

پශ්රී ලංකා

ジャパン

ジャパン

Australia

Australia

New Zealand

New Zealand

South Africa

South Africa