How To Engrave Metal?

- Home

- >

- Laser engraver materials

- >

- How To Engrave Metal?

Outline

How can I engrave metal?

Metal is a unique material with high reflectivity, hardness, and durability, and it is widely used across various industries. Metal engraving products often possess a high level of quality and longevity, but they also place specific demands on metal engraving tools.The method you choose depends on the type of metal, the desired outcome, and the tools available.

By hand

By machines

By chemical process

By lasers

Laser engraving uses a focused laser beam to vaporize the metal surface, creating precise and detailed designs. It is suitable for various metals like stainless steel, aluminum, and brass. Laser marking alters the surface texture rather than creating deep cuts, making it ideal for anodized aluminum and coated metals.

With speed, precision, and ability to handle intricate designs, lasers support more creative possibilities. It offers automated operation without manual control and requires minimal post-engraving cleanup.

Can a CO2 laser engrave metal?

A standard CO₂ laser cannot directly engrave bare metal because CO₂ lasers typically lack the power and wavelength required to mark or cut through metal. For direct engraving on bare metals, fiber lasers or more powerful specialized lasers are required. However, there are some ways to engrave metal with a CO₂ laser:

Coated or painted metals

Using a marking compound

Anodized aluminum

CO₂ lasers can effectively engrave anodized aluminum, as the anodized layer reacts well to the laser, creating high-contrast metal markings.

Fiber Laser: the optimal solution for metal engraving

Among all types of lasers, fiber laser is the best choice for metal engraving. They are highly efficient for metals like stainless steel, aluminum, and brass, offering deep, precise, and permanent markings. These machines can deliver exceptional results in industrial and professional settings, particularly when high precision and durability are essential.

Main advantages

- Precision and Detail: Fiber lasers provide high-resolution engraving, capable of producing intricate and detailed designs on various metals.

- Versatility: Suitable for a wide range of metals, including stainless steel, aluminum, brass, and titanium.

- Speed: Fiber lasers operate quickly, making them efficient for both single items and large production runs.

- Durability: The engravings are permanent and resistant to wear, making them ideal for industrial and commercial applications.

- Minimal Maintenance: Fiber lasers have a long lifespan and require little maintenance, reducing operational costs over time.

- Automation Compatibility: Can be integrated into automated systems for mass production, enhancing productivity.

- Customization and Flexibility: Fiber lasers allow for easy adjustments in design, depth, and texture, making them versatile for both simple and complex projects.

How to do laser engraving on metal?

Basic Steps

1. Select the right laser

Depending on the type of metal, choose a suitable laser machine. For example, fiber lasers are ideal for direct engraving on metals like stainless steel, aluminum, and brass, while CO₂ lasers require a marking compound for metal engraving, or it can directly engrave coated metal and anodized aluminum.

2. Prepare the metal surface

Cleaning tools

- Lint-free cloth or microfiber cloth

- Mild solvent (e.g., rubbing alcohol, acetone)

- Degreaser (for heavily soiled metals)

Cleaning process

- Wipe the surface with the solvent using the cloth to remove dirt, grease, and oils.

- For tougher contaminants, apply a degreaser, then clean with the cloth.

3. Set laser parameters

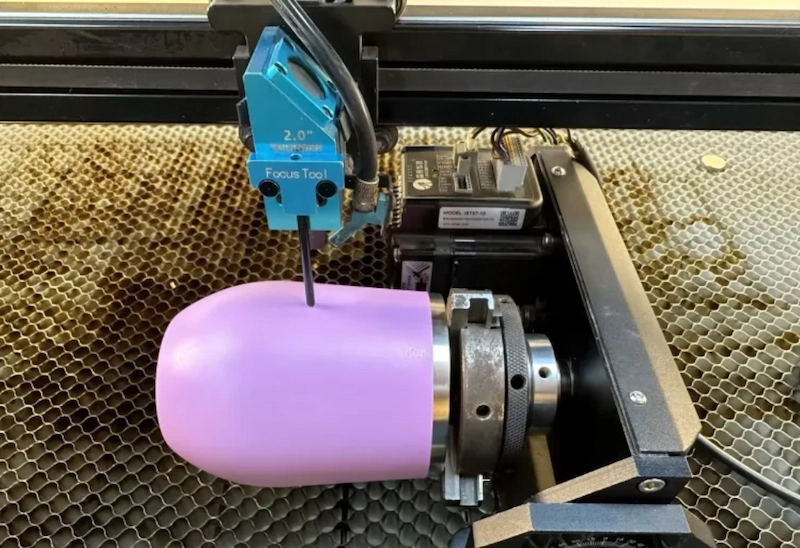

4. Position the metal

How to position properly when using a rotary device?

- Secure the Object: Ensure it's tightly held by the rotary clamps or rollers.

- Align the Axis: Center the object's axis with the laser's focal point.

- Level the Object: Use a level tool to keep the object horizontal.

- Set the Start Point: Align the laser's starting position with your design.

- Test Run: Use the laser's frame function to check alignment before engraving.

5. Engrave the metal

6. Finish the engraving

After engraving, clean the metal to remove any residue or marking compound. Depending on the application, you may want to polish the engraved area for a smoother finish. You can clean the metal

- Brush or wipe away residue gently.

- If necessary, use a mild solvent or abrasive pad to remove any remaining debris, being careful not to scratch the metal.

How to enhance the laser engraved metal?

- Color Filling: Apply paint or resin to the engraved areas to add contrast.

- Protective Coating: Use clear lacquer to prevent corrosion or tarnishing.

- Polishing: Buff the metal to achieve a refined finish that makes the engraving stand out.

Tips and tricks for laser engraving metal

How to darken laser engraving on metal?

Use a laser marking spray

Adjust laser settings

To engrave metal-coated cups or other cylindrical metal objects, you should use a rotary device to hold and rotate the object while metal engraving. Secure the item in the rotary device, align it with the laser, and ensure it is level. Once positioned, set the start point, run a test to check alignment, and then proceed with the engraving. The rotary device ensures that the laser evenly engraves around the curved surface.

Apply a black paint fill

How to engrave cylindrical metal objects like coated cups?

To engrave metal-coated cups or other cylindrical metal objects, you should use a rotary device to hold and rotate the object while metal engraving. Secure the item in the rotary device, align it with the laser, and ensure it is level. Once positioned, set the start point, run a test to check alignment, and then proceed with the engraving. The rotary device ensures that the laser evenly engraves around the curved surface.

Can laser engraving color on metal?

Yes, certain metals can undergo laser color engraving, particularly with specialized fiber lasers. The process involves controlling the laser’s power and speed to create oxide layers on the metal surface, which produce different colors. However, it’s mainly effective on stainless steel and titanium, and the process requires precise settings.

Parameters for laser engraving metal

The cutting effects in metal laser engraving are intricately tied to the material itself. Even when dealing with metals of the same thickness and type, variations in origin, batch, and production methods may lead to differences, ultimately influencing the cutting outcome.

To optimize metal laser engraving in fiber laser engraving machines, consider these parameters. Adjust them as needed to achieve the desired and suitable cutting results, taking into account the specific characteristics of the metal being processed.

| Material | Carve Effect | Speed(mm/s) | Power(%) | Rate(KHz) | Unidirectional or Bidirectional | Pass |

|---|---|---|---|---|---|---|

| 304 stainless steel | black | 200 | 10 | 100 | bidirectional | 10 |

| white | 1000 | 20 | 70 | bidirectional | 1 | |

| carbon steel | black | 100 | 10 | 50 | bidirectional | 1 |

| white | 900 | 20 | 60 | bidirectional | 1 | |

| brass | black | Not suitable for carving into black | ||||

| white | 500 | 20 | 50 | bidirectional | 1 | |

| aluminium | black | Not suitable for carving into black | ||||

| white | 900 | 20 | 60 | bidirectional | 1 | |

- Tags

#how to engrave metal, #metal engraving, #metal engraving tools, #metal marking, #laser metal engraving, #fiber laser, #co2 laser, #diode laser

.png) International

International

United States

United States

Brasil

Brasil

Canada

Canada

Costa Rica

Costa Rica

Mexico

Mexico

Česká

Česká

Romania

Romania

Polska

Polska

Ireland

Ireland

Portugal

Portugal

Lietuva

Lietuva

Россия

Россия Deutschland

Deutschland

Britain

Britain

Україна

Україна

France

France

Sverige

Sverige

Italia

Italia

Norway

Norway

Denmark

Denmark

Ελλάδα

Ελλάδα

한국

한국

中国

中国

ประเทศไทย

ประเทศไทย

中国香港

中国香港

Israel

Israel

中國臺灣

中國臺灣

India

India

پاکستان

پاکستان

پශ්රී ලංකා

پශ්රී ලංකා

ジャパン

ジャパン

Australia

Australia

New Zealand

New Zealand

South Africa

South Africa