Laser Cut Mother Of Pearl: Unlocking Your Creativity

- Home

- >

- Laser engraver materials

- >

- Laser Cut Mother Of Pearl: Unlocking Your Creativity

Outline

What is Mother of Pearl?

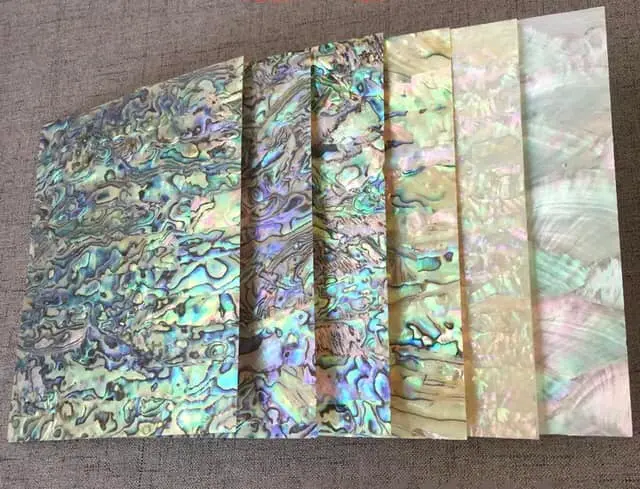

Mother of Pearl (MOP) is a unique and natural material that comes from the inner shell layer of mollusks like oysters and abalones. Known for its iridescent sheen, it is made primarily of calcium carbonate, giving it a delicate yet durable structure. Mother of Pearl is often used in decorative applications due to its beautiful luster and organic appearance.

When used as a laser material, Mother of Pearl is well-suited for laser processing because of its relatively thin structure and smooth surface. However, its composition requires precise settings to avoid burning or cracking during laser processing.

Can you cut mother of pearl with a laser cutter?

Yes, Mother of Pearl (MOP) can be efficiently cut with a laser cutter, offering a precise and effective method for working with this delicate material. The non-contact nature of laser cutting ensures that the intricate details and natural structure of MOP are preserved without causing unnecessary stress to the material. Additionally, laser cutting produces clean edges and minimizes material loss compared to traditional cutting methods, making it an ideal choice for intricate designs.

Laser cutting MOP is commonly applied in a variety of fields like jewelry and home decorations. However, there are important considerations to keep in mind when laser cutting Mother of Pearl. With appropriate settings and precautions, a laser cutter can unlock the full potential of Mother of Pearl, enabling stunning designs and enhancing creative projects across multiple industries.

Laser cut mother of pearl ideas

- Home decoration

- Jewelry

- Guitar designs

Find more laser projects and designs in our sample library!

How to laser cut mother of pearl?

1. Choose the right laser cutter for MOP

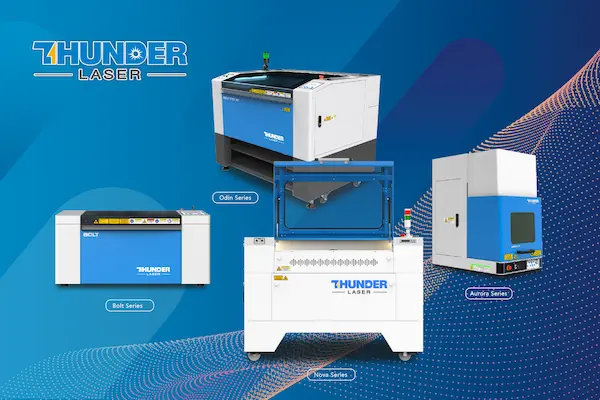

Not sure which laser cutter to choose for mother of pearl? Thunder Laser CO2 laser machines can process MOP, but the best choice depends on the focus of your laser project.

First, we recommend the Thunder Laser Nova Laser Cutter as your top choice. The Nova offers a larger working platform, and its pass-through doors allow for the placement of larger materials. It also boasts higher laser power, which makes it ideal for cutting mother of pearl sheets efficiently. With a CO2 laser machine like Nova, you can process MOP and a variety of other non-metal materials, making it suitable for both individual and batch production to enhance efficiency.

The Thunder Bolt Pro Laser Engraver excels in engraving precision and speed, making it perfect for detailed work on mother of pearl sheets. It also features a large build size and high power, which ensures it can cut MOP effortlessly while meeting enterprise-level demands for fine processing. If precision in laser cutting and engraving is a priority for you, this is an excellent choice.

2. Do a test to find an suitable laser parameter

This step is essential for achieving precise and high-quality results while minimizing potential damage to the material.

Mother of pearl is a delicate material with a natural structure that can be sensitive to excessive heat. Using inappropriate laser settings might lead to discoloration, cracking, or warping. Therefore, testing helps you identify the right balance of laser power, speed, and resolution to achieve clean cuts or engravings without compromising the material’s quality.

Start by preparing a small piece of MOP for testing. Set your laser cutter to low power and medium speed as a baseline, then incrementally adjust the parameters during the test. Observe how the material reacts to each setting, paying attention to the clarity of the cut, the edges’ smoothness, and any signs of overheating.

Through this process, you can identify the optimal settings that allow the laser to process MOP efficiently while preserving its natural beauty and structural integrity. Always document the successful parameters for future projects to save time and ensure consistency.

Learn more: laser settings for different materials

3. Start your laser magic

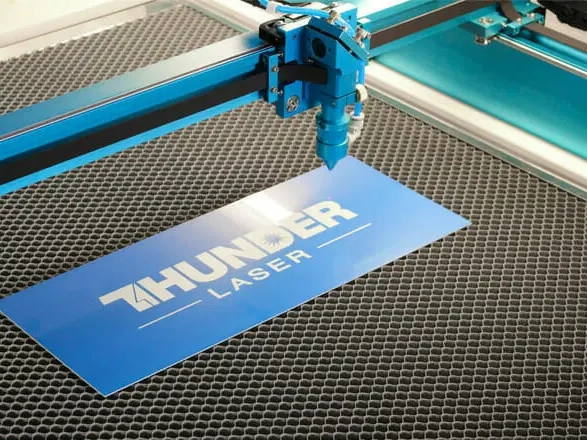

Once you have determined the optimal laser parameters for mother of pearl, you can proceed with the actual cutting or engraving process.

Prepare the Material and Machine: Place the mother of pearl sheet flat on the laser bed. Use masking tape or transfer tape to secure the material and minimize heat damage or debris buildup. Ensure the laser cutter’s bed is clean and aligned to prevent imperfections during cutting.

Set Up the Design: Upload your design to the laser software. Double-check the size and positioning to ensure it fits within the material’s boundaries.

Monitor the Process: During the operation, keep a close eye on the laser cutter. Mother of pearl can release small amounts of smoke or dust, which might accumulate on the laser lens or mirrors. If this occurs, pause the process and clean the machine to avoid compromising the laser’s accuracy.

Inspect the Finished Product: Once the process is complete, carefully remove the mother of pearl piece from the laser bed. Inspect the edges and engraved areas for any imperfections, and sand or polish them if necessary.

How to create wood inlays with mother of pearl?

First, it is best to use the same laser machine for processing both materials. Differences between machines, such as variations in dimensions, power, or precision, can result in mismatched cuts that are difficult to align properly.

Second, use fixtures to secure the materials in place. This can involve chiseling out cavities in the wood or employing other positioning methods to ensure the laser cutter accurately processes both materials in the correct alignment.

Finally, when adhering the mother of pearl to the wooden item, apply glue to the back of the mother of pearl rather than directly onto the wood. This prevents excess glue from seeping onto the surface and ensures a clean finish. By following these steps, you can create high-quality wood inlays with mother of pearl.

For a more detailed walkthrough, check out the Turn Touch case study, which offers additional insights into this process.

Tips and tricks for laser cut mother of pearl

1. How to avoid chipping when laser cutting mother of pearl?

2. How to prevent discoloration on mother of pearl during laser cutting?

3. How to clean mother of pearl after laser cutting?

4. How to handle minor flaws in mother of pearl pieces?

How to store laser-cut mother of pearl?

Firstly, store laser-cut mother of pearl in a cool, dry place to prevent moisture absorption, which can weaken the material or cause discoloration over time. Avoid areas with high humidity or fluctuating temperatures to ensure the material stays in optimal condition.

Secondly, use soft padding materials like bubble wrap or tissue paper to protect each piece. This prevents scratches or chips during handling and storage. If you are storing multiple pieces, avoid stacking them directly on top of one another. Instead, use dividers or separate layers to maintain their surface quality.

Additionally, mother of pearl should avoid contact with perfumes and body lotions, as these substances can alter its iridescent surface, dulling its natural sheen and beauty. You should ensure that any perfume or lotion has fully dried on your skin before wearing it. It’s recommended to wait at least 10 minutes after applying these products to minimize the risk of damage.

For long-term storage, keep the pieces away from direct sunlight and heat sources, as excessive exposure can dull their natural luster. A stable environment with controlled temperature and minimal light is ideal to preserve the beauty and durability of mother of pearl.

- Tags

#mother of pearl, #laser, #laser cutting, #laser cut mother of pearl, #co2 laser, #laser machine, #laser cutter

.png) International

International

United States

United States

Brasil

Brasil

Canada

Canada

Costa Rica

Costa Rica

Česká

Česká

Ελλάδα

Ελλάδα

Polska

Polska

Ireland

Ireland

Portugal

Portugal

Lietuva

Lietuva

Россия

Россия Deutschland

Deutschland

Britain

Britain

Україна

Україна

France

France

Sverige

Sverige

Italia

Italia

Norway

Norway

Denmark

Denmark

Romania

Romania

한국

한국

中国

中国

ประเทศไทย

ประเทศไทย

中国香港

中国香港

Israel

Israel

中國臺灣

中國臺灣

India

India

پاکستان

پاکستان

پශ්රී ලංකා

پශ්රී ලංකා

ジャパン

ジャパン

Australia

Australia

New Zealand

New Zealand

South Africa

South Africa