Laser Cut Paper: The Perfect Solution for Creative Projects

- Home

- >

- Laser engraver materials

- >

- Laser Cut Paper: The Perfect Solution for Creative Projects

Outline

How do you make a perfect cut for paper?

Paper is an easy-to-process material that can be transformed into a variety of beautiful or practical products using different methods, and which method will you choose for cutting it? Unlike traditional paper processing tools, laser cutting machines allow you to cut and engrave any paper project with precision. When used effectively, they can even replace tools like carving knives and utility knives, making integration seamless and significantly enhancing processing quality and efficiency.

If you had to choose just one tool for efficient and high-quality processing, it would undoubtedly be a laser machine. It saves time and effort while perfectly reproducing your designs, cutting out intricate patterns and fine lines with exceptional accuracy.

What type of paper can be laser cut?

Paper is a lightweight and versatile material, making it ideal for laser cutting due to its ease of processing. The thin and flexible nature of most paper allows for high precision and intricate designs, while the thick cardboard offers excellent hardness and toughness.

As a result, paper’s widespread availability and variety of types offer numerous creative possibilities. Many types of paper can be used for laser cutting, each offering unique properties for different projects.

- Cardstock

- Construction paper

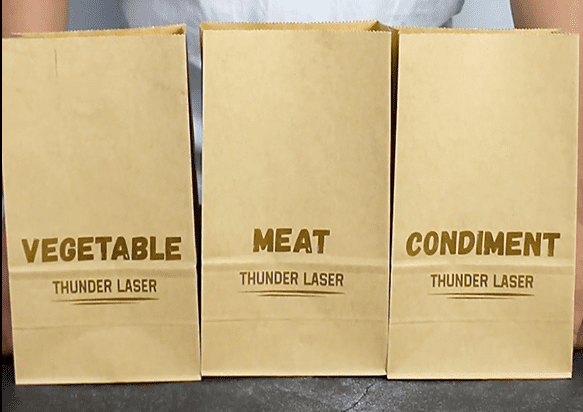

- Kraft paper

- Vellum paper

- Tissue paper

- Watercolor paper

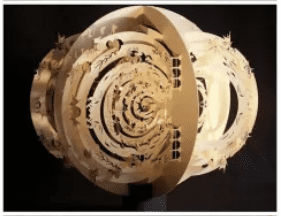

Creative laser cut paper ideas

Laser cutting paper opens up the possibility to create a wide variety of exciting products! Compared to manual methods, laser cutting allows for more precise and efficient processing, enabling a broader range of creative possibilities. Some of the most popular and widely used laser-cut paper products on the market include window decals, greeting cards, laser-cut invitations, and business cards, as well as the quick and efficient mass production of cardstock packaging.

- Birthday card

- Arts and crafts

- Business card

Greeting card ideas

How to laser cut paper at home?

Basic steps

- Prepare the design: Use design software like Adobe Illustrator or CorelDRAW to create your pattern or select a pre-made template.

- Choose the right paper: Use standard paper, cardstock, or craft paper. Thicker paper like cardboard can also be used, but requires adjusting the laser settings accordingly.

- Set up the laser cutter: Import your design into the laser cutter software like LightBurn, then adjust the settings. Use lower power and higher speed to prevent burning the edges.

- Test on scrap paper: Always do a test cut on spare paper to fine-tune the power and speed settings before starting your final project.

- Laser cut: Once the settings are good, place the paper in the machine, align it, and start the cutting process.

- Monitor the process: Stay nearby and keep an eye on the machine to avoid paper catching fire due to the heat from the laser.

Choose a laser cutting machine that suits your need!

You need the right laser machine to power your creativity! If space is limited at home, what kind of machine should you consider? Undoubtedly, a desktop laser machine is ideal.

The Thunder Bolt Desktop Engraver perfectly meets the needs of home creators: compact, all-in-one, efficient, convenient, and versatile across materials. With its speed up to 2000mm/s and sufficient 30w power, it’s capable of delivering precise engraving and cutting processes on paper and other materials. You can use it to fully process paper and turn your ideas into reality.

Of course, if you’re not limited to hobby projects or home-based work, you might consider larger models. The Bolt Pro offers enhanced precision and size for more advanced engraving, making it ideal for workshop-based, enterprise-level multi-material processing. The Nova Laser Cutter is larger and offers great value, designed for high-volume, large-area production.

What power laser is needed to cut paper?

A relatively low-power laser is needed to cut paper, as it is a lightweight and easily processed material. Typically, a CO2 laser with a power range of 10 to 40 watts is sufficient for cleanly cutting paper without excessive burning or charring. Lower power settings, such as 10-15 watts, are ideal for thin paper, while slightly higher settings can handle thicker materials like cardstock or cardboard.

The exact power will depend on the thickness and type of paper, but in most cases, low-wattage lasers perform effectively for this application.

What settings do you laser cut paper?

The following parameters of the laser paper-cutting machine Bolt Pro 32 are for reference only. For specific use, small-scale testing can be conducted first to adjust the parameters to fit.

named layers | Speed (mm/S) | Power (%) | Single and Double Direction | Line Interval/DPI | Blow Type | Blow Value |

shallow carving | 1500 | 60 | Horizontal Double | 300 | weak | 0.1 |

deep carving | 1000 | 90 | Horizontal Double | 300 | Strong | 1.6 |

cutting | 25 | 60 |

|

| Strong | 1.6 |

running a line | 100 | 10 | Horizontal Double |

| weak | 0.1 |

Tips and tricks for better laser cutting paper

How to laser cut paper without burning?

The following methods can be used to prevent ignition because paper is a combustible material.

1. Make sure the proper frequency, speed, and power are chosen and using too much power can quickly carbonize the cardboard in laser paper cutting machine.

2. Using an air compressor to blow air to provide a flame retardant effect is advised.

How to prevent paper from warping during laser cutting and blowing?

It is well known that paper has a low ignition point and is highly flammable, so we recommend using air assist during processing to reduce fire risk. However, this blowing process can cause the paper to warp. To prevent this, we can implement the following measures:

Use High-Quality Paper: Select paper specifically designed for laser cutting or tougher materials like cardboard, as they tend to have better dimensional stability.

Adjust Laser Settings: Optimize laser power and speed settings to minimize excessive heat buildup, which can lead to warping. A faster cutting speed with lower power can help.

Use a Flat Cutting Surface: Ensure that the paper lies flat on the cutting bed to prevent uneven cutting and subsequent warping. You can also use magnets or weights to secure it in place.

How to store the paper after finishing laser cutting?

1. Keep the board dry and ventilated in a room temperature setting. The laser machining paper should not be exposed directly to heat, sunlight, or moisture.

2. The storage room must be kept tidy to discourage rodents and insects from devouring paper products.

3. To avoid contamination with dust, which is difficult to remove, the paper material should be laid out properly flat and preferably covered with a plastic protective bag. That is a good storage method to store when not needed to be placed in a laser paper cutter machine for production.

- Tags

#paper cutting, #laser cut paper, #laser engraver for paper, #paper cutting machine, #paper for laser cutting, #how to laser cut paper at home, #how do you laser cut paper

.png) International

International

United States

United States

Brasil

Brasil

Canada

Canada

Costa Rica

Costa Rica

Mexico

Mexico

Česká

Česká

Romania

Romania

Polska

Polska

Ireland

Ireland

Portugal

Portugal

Lietuva

Lietuva

Россия

Россия Deutschland

Deutschland

Britain

Britain

Україна

Україна

France

France

Sverige

Sverige

Italia

Italia

Norway

Norway

Denmark

Denmark

Ελλάδα

Ελλάδα

한국

한국

中国

中国

ประเทศไทย

ประเทศไทย

中国香港

中国香港

Israel

Israel

中國臺灣

中國臺灣

India

India

پاکستان

پاکستان

پශ්රී ලංකා

پශ්රී ලංකා

ジャパン

ジャパン

Australia

Australia

New Zealand

New Zealand

South Africa

South Africa