- Author: Cathy

Brass and copper are beautiful yet challenging materials to engrave. Whether you’re personalizing jewelry, creating industrial nameplates, or adding artistic touches, using the right laser and settings is essential for clean, durable results. This guide explains the best techniques, tools, and prep tips for engraving brass and copper efficiently and safely.

What is the best way to engrave brass and copper?

The best way to engrave brass and copper is using a fiber laser, as it is specifically designed for metals and offers high precision with minimal surface damage. Fiber lasers can penetrate the metal without causing significant heat distortion, making them ideal for fine and detailed engraving. Alternatively, a UV laser can also be used for engraving brass and copper. It’s more expensive and slower but generates less heat than fiber lasers, allowing for even more precise control and reducing the risk of heat damage to the material.

For traditional, non-laser methods, hand engraving with specialized tools such as burins or gravers is another option, though it requires skill and patience. While hand engraving offers a more personal touch, it is often slower and less precise than lasers.

Can you etch copper and brass with CO2 laser?

Advantages of laser engraving brass and copper

Precision

Non-contact process

Minimal heat distortion

Permanent marking

What can you create with laser engraving brass and copper?

- Jewelry (rings, bracelets, ...)

- Nameplates and plaques

- Business cards

- Personalized gifts

- Electrical tags

- Signage

- Medals and badges

- Machine and tool labels

- Coins or tokens

- ...

Thrive with THUNDER LASER metal marker!

How do you prepare copper and brass for engraving?

Clean the surface

Apply a marking spray (if using a CO2 laser)

How to Blacken Engraved Brass or Copper

- Lightly clean off any powder or dust from the recently engraved design.

- Pour the blackening agent directly onto the engraving, ensuring the engraved areas are fully submerged.

- Let it sit and soak for at least 15 minutes.

- Drain the solution, then scrub the brass with steel wool in clean water.

- Lightly polish the engraved surface with a buffing machine to make the details clearer.

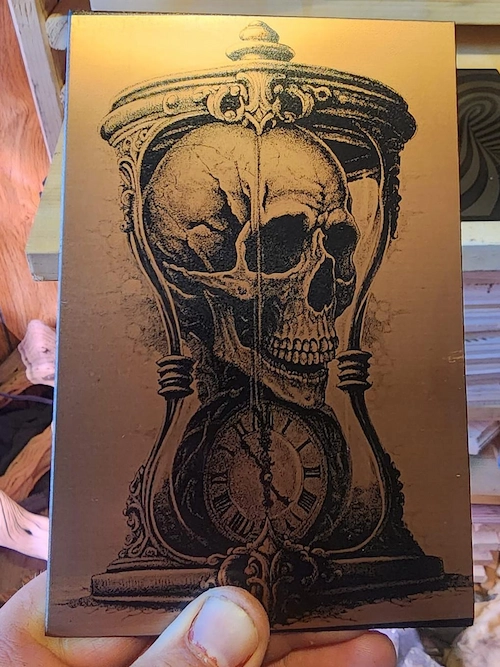

Before and after comparison of the blackening effect

Best laser marker for engraving brass and copper!

You need a professional laser machine to help you with better laser engraving brass and copper! The Thunder Aurora is designed specifically for metal engraving, and its standard fiber laser can produce intricate results on brass and copper. With speeds of up to 8000mm/s, the Aurora ensures fast and precise marking while also allowing the creation of more textured 3D relief effects.

Thunder Aurora’s all-in-one desktop design makes it easy to create laser projects anytime, anywhere. Despite its compact size, the Aurora boasts powerful processing capabilities. Simply select your design on the computer, make quick adjustments on the control panel, and the processing starts. It supports most bare and coated metals.. If you require more versatility for non-metal materials, you can also opt for a UV laser for broader material applications.

What setting do you laser mark brass?

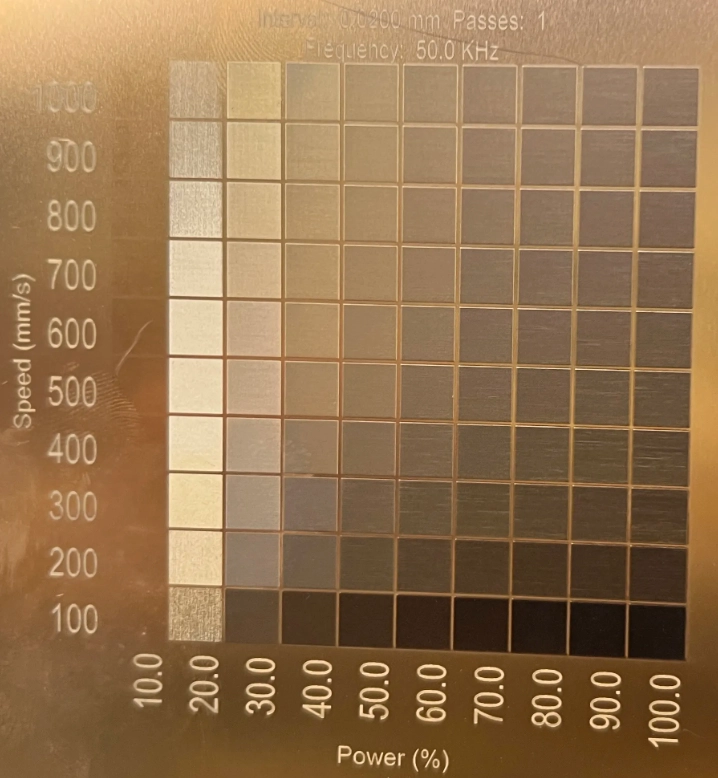

| Marking results | Speed(mm/s) | Power(%) | Frequency(kHz) | Fill mode | Line interval(mm) | No. of passes |

|---|---|---|---|---|---|---|

| Black | 100mm/s | 10 | 50 | Bi-directional | 0.02mm | 1 |

| White | 400mm/s | 30 | 50 | Bi-directional | 0.02mm | 1 |

Here are the parameters we obtained for fiber laser engraving brass after testing with the Aurora Lite-50W, which you can use as a reference for your own brass processing. During our machine testing, the most suitable frequency was 50kHz.

Changing the settings can yield different color results. You also can refer to the images and adjust the settings during your own tests to achieve the desired effect.

Conclusion

Laser engraving brass and copper opens the door to both functional and decorative applications across many industries. With the right laser machine—like the Thunder Aurora—and careful material preparation, you can achieve stunning results with speed and precision. Whether you’re a hobbyist or a manufacturer, fiber or UV lasers provide the durability and detail brass and copper demand.

Need help getting started? Explore our Aurora metal marker or contact our support team for guidance.

- Tags

#laser engraving brass, #laser engraving copper, #brass, #copper, #metal laser engraving, #can you laser engrave brass, #laser etching copper, #fiber laser, #co2 laser

.png) International

International

United States

United States

Brasil

Brasil

Canada

Canada

Costa Rica

Costa Rica

Mexico

Mexico

Česká

Česká

Romania

Romania

Polska

Polska

Ireland

Ireland

Portugal

Portugal

Lietuva

Lietuva

Россия

Россия Deutschland

Deutschland

Britain

Britain

Україна

Україна

France

France

Sverige

Sverige

Italia

Italia

Norway

Norway

Denmark

Denmark

Ελλάδα

Ελλάδα

한국

한국

中国

中国

ประเทศไทย

ประเทศไทย

中国香港

中国香港

Israel

Israel

中國臺灣

中國臺灣

India

India

پاکستان

پاکستان

پශ්රී ලංකා

پශ්රී ලංකා

ジャパン

ジャパン

Australia

Australia

New Zealand

New Zealand

South Africa

South Africa