- Author: Cathy

Laser engraving on acrylic is a highly effective way to create detailed designs, from personalized ornaments to striking signage. With the right laser technology, you can achieve clean, precise engravings that stand out in both aesthetic appeal and durability. In this guide, we’ll explore the best practices, materials, and machine specifications for working with acrylic.

1. Can you Laser Engrave Acrylic?

Yes, laser can engrave acrylic by emitting a focused beam of light and leaving unique results. It is usually a matte, white, or translucent texture that contrasts with the smooth, transparent areas of the acrylic that have not been engraved. Laser engraving on acrylic enables you to create clear markings, text, patterns, and complex designs on acrylic, making it popular for signs, plaques, art pieces, and decorative items.

Advantages of Laser Engraving on Acrylic

- High Precision: Intricate and detailed designs.

- Smooth, Clean Edges: No rough edges or residue.

- Frosted Finish: A clear, frosted effect on the surface.

- Versatile Applications: Suitable for signs, art, awards, etc.

- Durable Markings: Long-lasting and resistant to wear.

2. Best Acrylic for Laser Engraving - Cast Acrylic

- Engraving Quality

- Versatility

- Durability

Is Extruded Acrylic Suitable for Laser Engraving?

When engraved, extruded acrylic tends to produce a smoother, more transparent finish rather than the frosted, white effect that cast acrylic offers. This can make the engraved designs less visible and less distinct. Additionally, extruded acrylic has a lower melting point, which can lead to more melting and less precise engravings.

While it can be used for laser cutting with good results, for engraving, especially where detail and contrast are important, cast acrylic is the preferred choice.

3. Suitable Laser Tubes for Acrylic Laser Engraving

The choice of laser source plays a crucial role in determining engraving quality, efficiency, and material compatibility. Different types of laser tubes interact with acrylic in distinct ways, affecting depth, edge finish, and design clarity. Understanding the core differences between CO₂, diode, and UV lasers helps in selecting the most suitable option for your project’s specific needs. The following outlines their respective advantages and limitations when working with acrylic.

3.1. CO2 Lasers

3.2. Diode Lasers

3.3. UV Lasers

4. What Can you Create?

- Ornaments

- Awards

- Photos

- LED light

How to Prepare Acrylic for Laser Engraving?

Clean the Acrylic

Ensure the acrylic sheet is clean and free from dust, fingerprints, or any debris. Wipe it down with a soft cloth to prevent any imperfections in the engraving.

Keep the Protective Film

Leave the protective film on the acrylic while engraving to prevent scratches. If your acrylic doesn’t have a protective film, you can apply masking tape to both sides.

Position the Acrylic on the Laser Bed

Place the acrylic sheet flat on the laser bed, ensuring it is secure and does not move during the engraving process. If necessary, use weights or clamps to hold it in place.

5. How to laser engrave acrylic?

Before diving into techniques for reducing surface imperfections or achieving cleaner finishes, it’s helpful to understand the full engraving process from start to finish. The following case study provides a practical example of how to laser engrave and cut acrylic effectively—covering everything from parameter setup to final cleaning. This hands-on walkthrough serves as a foundation for applying more advanced techniques like minimizing frosting or improving clarity.

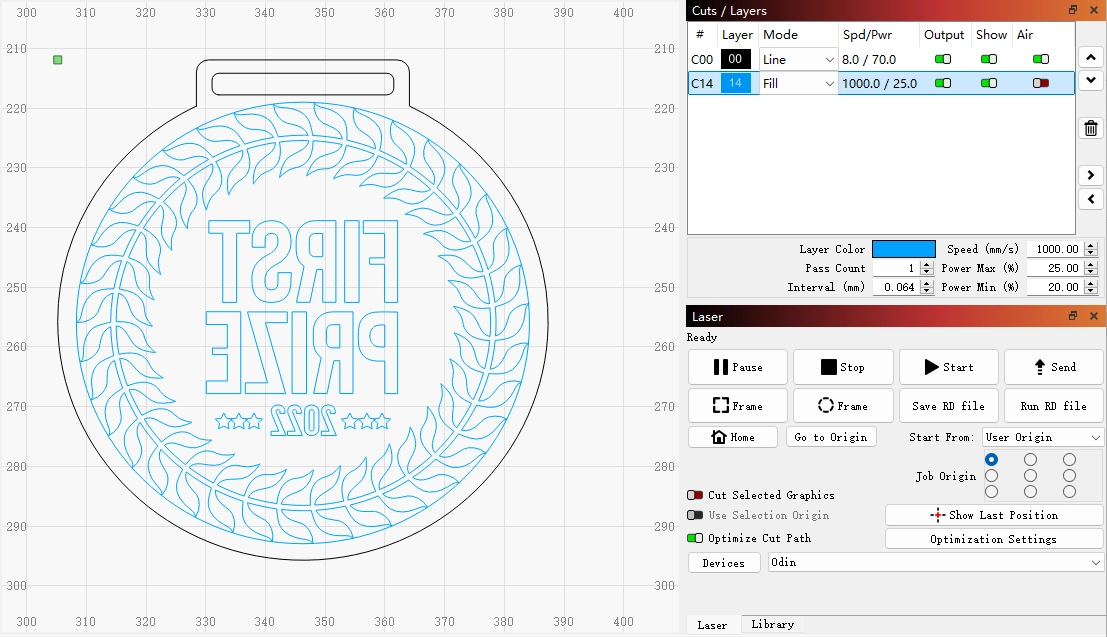

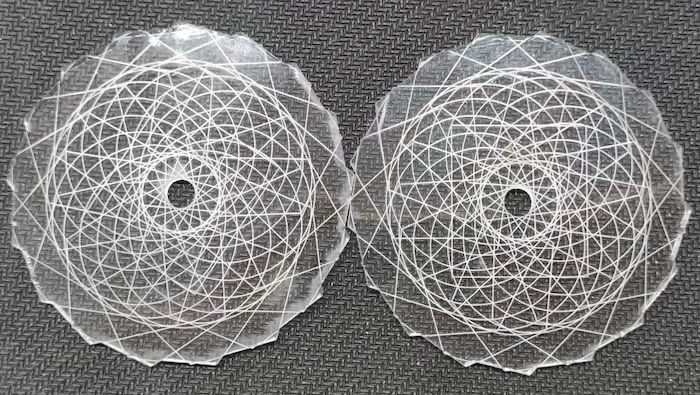

5.1. Case study: Making an Acrylic Laser Engraving Award

Nothing explains better than hands-on practice. We’ve introduced important considerations for engraving acrylic through a real-world case of creating an acrylic medal. You can also follow along by opening your software like lightburn and laser machine. Try it out yourself!

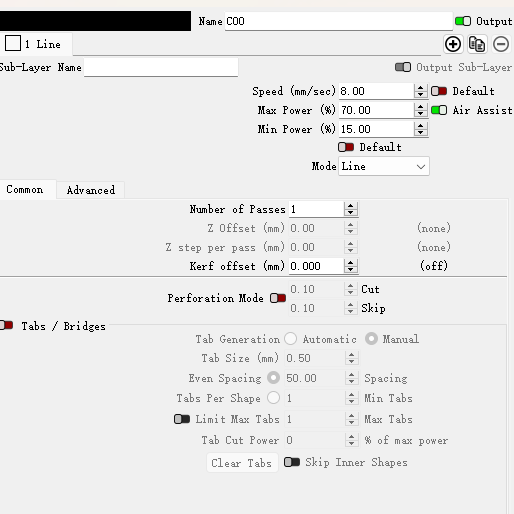

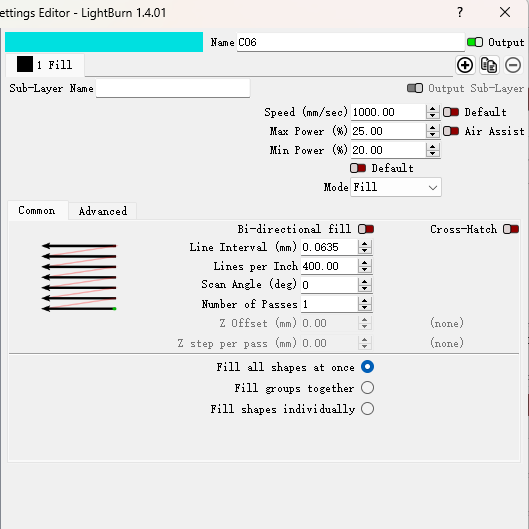

- Adjust appropriate parameters

Mirror the Image for Acrylic Engraving: Since engraving is usually done on the backside, mirroring may be necessary.

Confirm Unidirectional or Bidirectional Fill: Because the effects differ, with unidirectional fill providing better results but taking more time.

DPI Setting: Typically set to 300. The higher the DPI, the more lines there are, and the deeper the engraving will be.

Enable Strong Air Assist for Cutting: This reduces the risk of fire.

Advanced Options: Ensure the slope value is set to “0”.

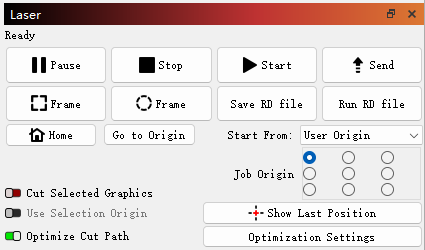

- Position and Send the File

Set the starting position to the midpoint for easier subsequent positioning and border tracing.

Click the “Send” button to send the file to the machine. Use a simple and easy-to-find name for the file. Click “Confirm” to complete the file preparation.

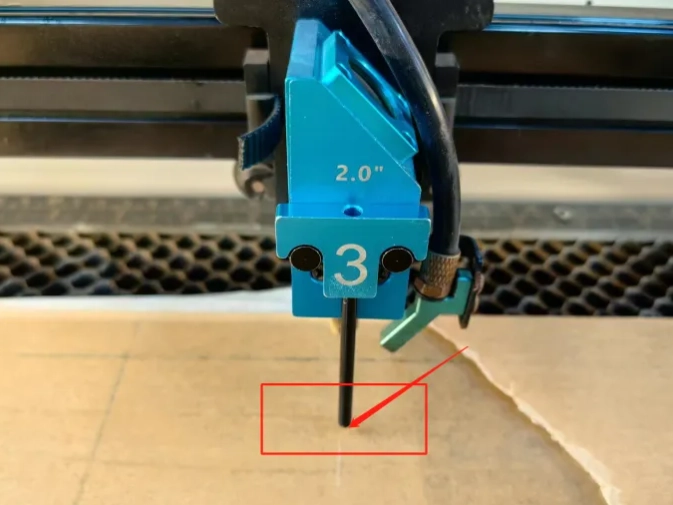

- Focus

- Select and Confirm the File

- Confirm Positioning

- During Laser Processing

Engraving process

- Clean up

5.2. How to Engrave Clean Acrylic by Reducing "Frosting"?

5.3. Laser Engrave from Bottom to Top

5.4. Apply Dish Soap to the Surface

Dish soap acts as a flame retardant and can effectively prevent the acrylic surface from warping and producing frosty residues. Before engraving, evenly apply a thin layer of dish soap to the acrylic surface. Afterward, gently rinse off the excess soap to achieve a clean finish. It not only prevents surface warping but also helps keep the material clean. You can also apply this technique when engraving other plastic materials.

6. Best Laser Engraver for Acrylic

CO2 laser machines are undoubtedly the most effective laser engravers for acrylic. Diode lasers, with their lower power, have limited engraving efficiency and are only suitable for smaller projects. UV lasers can finely engrave acrylic but are not suitable for cutting. In contrast, CO2 lasers offer higher power and greater versatility, making them ideal for a wide range of acrylic engraving projects, regardless of size or creative requirements.

You need a high-performance CO2 laser machine to power your acrylic engraving business! Our Thunder Bolt laser engraver is an excellent acrylic laser engraving machine. With speeds up to 1500mm/s, the desktop Thunder Bolt offers great value while allowing you to create finely engraved acrylic products.

The upgraded Thunder Bolt Pro, with speeds up to 2000mm/s, is larger in size, enabling you to work on bigger sheets while delivering exceptional precision in engraving. It’s a powerful tool for your laser business.

7. Parameters for Laser Engraving Acrylic

Different parameters can produce varying results on laser engraving on acrylic. Using the Thunder Bolt machine as an example, we have set different parameters for engraving images, text, and labels for your reference.

| Processing | Speed (mm/s) | Power(%) | Hatch type | DPI | Blow type |

|---|---|---|---|---|---|

| shallow carving (image) | 500 | 15 | Horizontal Double | 300 | weak |

| shallow carving (text) | 500 | 18 | Horizontal Double | 300 | weak |

| shallow carving (label) | 500 | 20 | Horizontal Double | 300 | weak |

Conclusion

Whether you are engraving intricate awards, custom gifts, or decorative items, choosing the right tools and techniques is crucial for success. Thunder Laser’s Bolt series offers exceptional precision and speed, making it an ideal choice for any acrylic engraving project. Unlock your creative potential with the right equipment and expertise!

FAQs About Laser Engraving on Acrylic

Q1. How can I reduce the risk of acrylic cracking during laser engraving?

To prevent cracking, ensure the acrylic is properly secured and use lower power settings with a slower speed.

Q2. Can I laser engrave colored acrylic, and will it affect the results?

Yes, colored acrylic can be engraved, but the engraved design may have a different contrast depending on the color.

Q3. How do I remove protective film without damaging the acrylic?

Gently peel off the protective film after engraving, using a soft cloth to avoid scratching the acrylic surface.

Q4. How should I store engraved acrylic after laser engraving?

To preserve laser engraved acrylic, store it in a cool, dry place away from direct sunlight. Avoid stacking heavy objects on it to prevent scratches or pressure damage. If the acrylic has a protective film, keep it on until the engraving is ready for use. For extra protection, store the acrylic in a padded box or wrapping to prevent accidental impacts.

Q5. What is the best thickness of acrylic for laser engraving?

Typically, 3mm to 6mm thick acrylic is ideal for engraving. Thicker acrylic may require adjustments to the machine’s settings or multiple passes.

- Tags

#laser engraving on acrylic, #engraved acrylic, #acrylic for laser engraving, #how to laser engrave acrylic, #acrylic engraving machine

.png) International

International

United States

United States

Brasil

Brasil

Canada

Canada

Costa Rica

Costa Rica

Česká

Česká

Ελλάδα

Ελλάδα

Polska

Polska

Ireland

Ireland

Portugal

Portugal

Lietuva

Lietuva

Россия

Россия Deutschland

Deutschland

Britain

Britain

Україна

Україна

France

France

Sverige

Sverige

Italia

Italia

Norway

Norway

Denmark

Denmark

Romania

Romania

한국

한국

中国

中国

ประเทศไทย

ประเทศไทย

中国香港

中国香港

Israel

Israel

中國臺灣

中國臺灣

India

India

پاکستان

پاکستان

پශ්රී ලංකා

پශ්රී ලංකා

ジャパン

ジャパン

Australia

Australia

New Zealand

New Zealand

South Africa

South Africa