- Author: Cathy

Why is etching stainless steel difficult?

What is the easiest etching solution for stainless steel?

There are several methods to engrave stainless steel, including laser engraving, mechanical engraving, chemical etching, and hand engraving. Laser engraving uses high-powered lasers to precisely remove material from the surface, offering fast, detailed results without causing tool wear or significant heat distortion. Mechanical engraving, on the other hand, involves using cutting tools to physically carve designs, but this method can be slower, and it requires more maintenance. Chemical etching and hand engraving are alternatives that offer varying levels of depth and intricacy, though they tend to be less efficient or consistent for larger-scale projects.

Among these options, laser engraving is generally the best method for etching stainless steel. It provides the highest precision and speed, making it suitable for both detailed work and bulk production. While other methods have their uses, laser engraving delivers the cleanest, most reliable results with minimal effort and material distortion.

What is the best laser for engraving stainless steel?

Advantages of engraving stainless steel by fiber lasers

- High precision: Fiber lasers provide detailed and accurate engraving.

- Durability: The engraved marks are permanent and resistant to wear.

- Minimal heat distortion: They reduce the risk of warping or damaging the material.

- Speed: Fiber lasers can engrave stainless steel quickly, improving efficiency.

- Cost-effective: They offer long-term savings with minimal maintenance and operational costs.

Can a CO2 laser engrave on stainless steel?

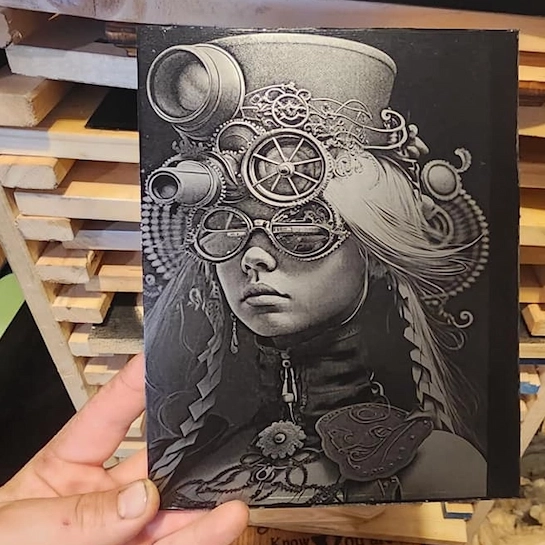

Creative stainless steel engraving ideas

Jewelry

Coated Tumblers

Photo Engraving

Dog Bowls

Bottle Opener

What wattage laser to engrave stainless steel?

How to enhance the quality of laser engraving on stainless steel?

1. What are the settings for laser etching stainless steel?

| Materials | Marking results | Speed (mm/s) | Power(%) | Frequency(kHz) | Hatch type | Line interval | No. of passes |

|---|---|---|---|---|---|---|---|

| 304 stainless steel | Black | 200 | 10 | 100 | Double | 0.02 | 10 |

| White | 1000 | 20 | 60 | Double | 0.02 | 1 | |

| Mirror-polished stainless steel | Black | 100 | 20 | 90 | Double | 0.02 | 10 |

| White | 700 | 20 | 70 | Double | 0.02 | 1 |

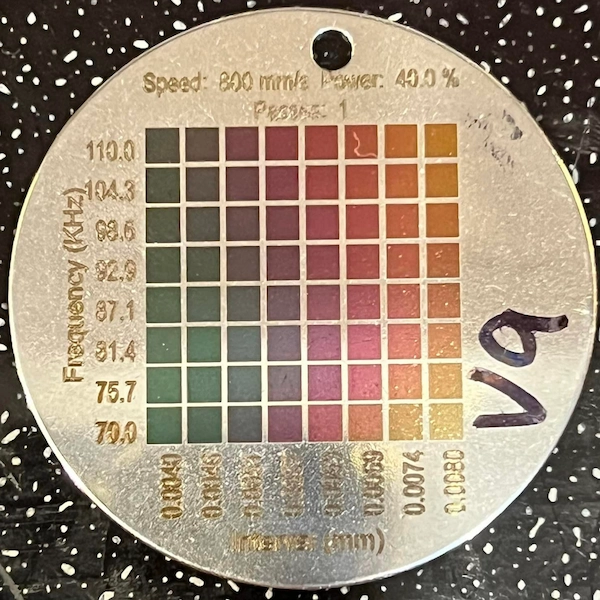

2. How to laser engrave color on stainless steel?

Laser engraving color on stainless steel is typically done using a fiber laser through a process called laser annealing. This process does not remove material but heats the surface of the metal to specific temperatures, which causes a controlled oxidation reaction. The varying temperatures produce different colors on the stainless steel, including shades of blue, brown, yellow, and even green. By adjusting the laser’s power, speed, and frequency settings, you can achieve a range of colors without using dyes or inks.

This method is commonly used for decorative purposes, branding, or product customization, as it creates durable, permanent colors directly on the metal. The results of processing may vary depending on the type of laser and power settings. Before creating the final product, it’s best to run multiple tests on stainless steel to achieve the desired outcome.

3. How to passivate stainless steel?

Passivating stainless steel is a process that removes free iron and other contaminants from the surface, restoring the metal’s corrosion resistance by forming a protective oxide layer. Here’s the steps:

Clean the surface: Start by thoroughly cleaning the stainless steel to remove any oils, dirt, or grease. Use a solvent or detergent suitable for stainless steel. For heavily contaminated surfaces, a pickling step can help remove oxides and scale before passivation. This involves using an acidic solution like nitric or hydrofluoric acid.

Passivation solution: Submerge or apply a passivating acid solution, typically nitric acid or citric acid, to the stainless steel. The acid dissolves free iron on the surface, leaving behind the chromium that forms a corrosion-resistant oxide layer.

Rinse thoroughly and dry: After the acid treatment, rinse the stainless steel with deionized water to neutralize the acid and remove any residues. Allow the stainless steel to air dry or use a clean, lint-free cloth to prevent water spots or contaminants from affecting the passivation.

How can you protect laser-engraved stainless steel from rust or corrosion?

Apply a Protective Coating: After engraving, apply a clear coat of protective oil, wax, or specialized sealant designed for metals. This creates a barrier that shields the steel from moisture and other corrosive elements.

Regular Cleaning: Clean the engraved surface with mild soap and water regularly to remove any contaminants that could lead to rust. Avoid using harsh chemicals or abrasive cleaners, which can damage the protective layer on stainless steel.

Best laser engraver for stainless steel!

The Aurora offers both fiber and UV laser sources, primarily designed for marking and engraving metal materials. The standard Aurora 8 and Aurora UV models can reach speeds of up to 2000mm/s, while the Aurora 8 Pro can achieve an impressive 8000mm/s. These machines allow you to efficiently and conveniently begin your laser projects. Despite their compact desktop size, Aurora machines deliver high-quality, efficient processing to support both your business and hobbies. They are capable of marking and engraving a wide range of metals, with the UV laser extending its capabilities to non-metal materials as well.

Stainless steel is a key application in Aurora’s metal processing capabilities. Through extensive testing, we have confirmed the effectiveness of the Aurora in engraving stainless steel, gaining valuable insights and creative ideas along the way. With this experience, we are confident that the Aurora is your best choice for a stainless steel laser engraver.

- Tags

.png) International

International

United States

United States

Brasil

Brasil

Canada

Canada

Costa Rica

Costa Rica

Česká

Česká

Ελλάδα

Ελλάδα

Polska

Polska

Ireland

Ireland

Portugal

Portugal

Lietuva

Lietuva

Россия

Россия Deutschland

Deutschland

Britain

Britain

Україна

Україна

France

France

Sverige

Sverige

Italia

Italia

Norway

Norway

Denmark

Denmark

Romania

Romania

한국

한국

中国

中国

ประเทศไทย

ประเทศไทย

中国香港

中国香港

Israel

Israel

中國臺灣

中國臺灣

India

India

پاکستان

پاکستان

پශ්රී ලංකා

پශ්රී ලංකා

ジャパン

ジャパン

Australia

Australia

New Zealand

New Zealand

South Africa

South Africa