Laser glass etching machines have revolutionized the way we personalize and decorate glass products. Whether you’re creating custom tumblers, wine bottles, or glass awards, these machines offer unmatched precision and versatility.

In this guide, we’ll explore how laser glass etching works, its advantages, the best glass materials to use, and popular products you can create with it.

Let’s dive in!

1. What Is a Glass Laser Etching Machine, and How Does It Work?

Laser etching on glass refers to one type of engraving process on glass materials. Although, the laser etching process has a limitation in the engraving depth. Laser etching can typically create marks on different materials, including glass. Usually, the process melts a portion of their surface and establishes a ditch. The maximum etching depth in the laser etching method is approximately 0.001″.

Laser etching on glass is a typical laser engraving process with a broader category. This category includes laser engraving and laser annealing. Laser etching is a versatile method. Thus it can easily create laser marks on any glass material type. It is important to note that a laser glass etcher makes permanent markings on glass, such as logos, names, codes, or serial numbers.

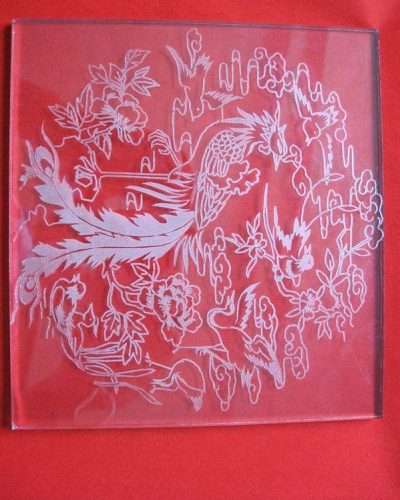

In a typical glass laser etching process, a high-energy laser falls on the surface of the glass and creates a desired marking. In this case, high color concentration requires high energy from the laser source. The most popular colors for laser-etched glass are black, white, or grey. However, in most cases, the laser glass etcher creates permanent marks without removing materials. Thus, the quality of the markings on the glass becomes more attractive and durable.

2. Advantages of Glass Laser Etching Machine

We already know that laser glass engravers are one type of laser marking machine. A laser etching machine for glass is typically faster than a laser engraver machine. However, we will discuss this machine’s benefits in the following.

2.1. High Precision

Laser beams are tiny as light particles. As a result, it can engrave every detail of a design. Therefore, you can precisely etch or mark any art on the glass using a laser glass etching machine. As laser etching is a non-contact process, the laser beam typically doesn’t affect the surroundings of the engraving area. As a result, products from a laser glass etching machine guarantee clean and high-quality marks.

2.2. Safety

The laser machine is entirely safe to operate. It is a non-contact and automated machine, one of the most important benefits of a laser etching machine for glass. As a result, this benefit of safety features is the main reason for investing in such laser machines. However, you can easily create a safe environment around the laser machine to etch glass. Above all, ensuring all employees working with a laser glass engraver are adequately trained is essential.

2.3. Versatility

You can almost work with any type and shape of glass for laser etching. This benefit of versatility also makes a laser marking machine for glass preferred for many applications. You can easily engrave flat-surface glass materials on the machine’s working table. On the other hand, in the case of cylindrical or conical shapes, you must use a rotary attachment for variable laser etching. However, laser glass etching machine can engrave glass and other materials such as acrylic, wood, or plastics.

2.4. Productivity

Laser etching can not make more ditches than a typical laser engraving machine. As a result, laser etching on glass is faster than laser engraving. Therefore, a laser marking machine for glass can complete the product faster, resulting in high productivity.

2.5. Value for Money

A glass laser etching machine is one of the most demanding laser machines in the market. Why? Because it has excellent value for money. This superb machine can make beautiful glass products that undoubtedly increase the value of your business. Customers typically like exclusive and meaningful designs. A laser glass etching machine is a choice where you can make exclusive glass products. Later, we will discuss more products from a laser etching glass machine.

3. Trendy Products of Glass Laser Etching Machine

Laser glass etching machines have a broad range of applications. Many glass products are famous in the jewelry, automotive, medical, and optics industries. Customized glassware, panels, mirrors, trophies, etc., are the most popular products of a laser etching glass machine.

3.1. Tumblers

Laser etched glass tumblers are becoming more and more popular globally. It is mainly popular among consumers and retailers. These glass tumblers are easy to make and don’t require much cost. Glass tumblers are prevalent in most local bars and gift shops. DIY projects only require a minimum power of a laser glass engraver and a rotary attachment.

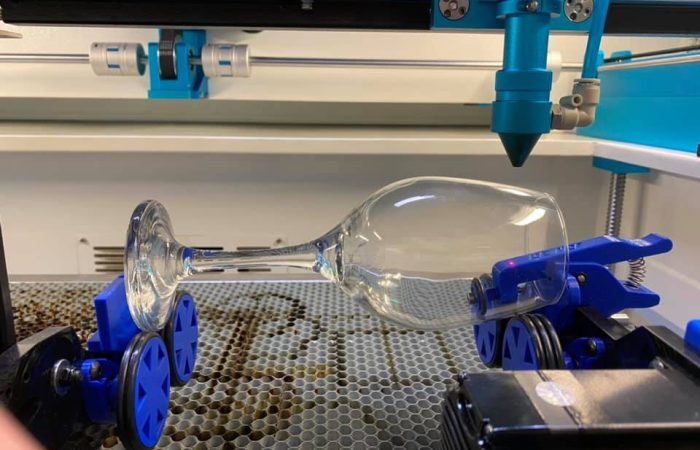

3.2. Wine Glass

Wine glasses are more delicate than glass tumblers. Due to its complex shape, sometimes it’s tricky to etch on wine glasses. As it’s tricky to engrave, this is where you can make more money. All you need to do is understand the tricks of the engraving process on wine glasses. In your business, you may offer all types of customized wine glasses and boutique glassware.

3.3. Wine Bottles

Wine bottles sometimes determine the elegance of the person offered. Nowadays, every wine bottles come with unique designs and logos. In this case, the more subtle engraving creates the more expensive bottles. Therefore, starting a laser-etched wine bottle business is profitable. In addition, it can be one of the best decisions for buying a laser glass engraving machine.

3.4. Ornaments

Glass earrings, bracelets, and necklaces are the best application of laser glass ornament products. People look for unique gifts for their beloved person in the coming holidays. These laser-etched glass products can be one of the best choices for such items.

3.5. Glass Awards and Trophies

Schools, universities, or training institutions are typically familiar with trophies and awards. These award items can be made of metal, wood, or glass. However, glass awards are the most popular among them.

3.6. Customized Glass Gifts

Besides the above laser etched products, there are other customized glass gifs you can come up with for your business ideas. Some common examples are construction equipment, keyrings, signage, shower doors, and glass partitions.

3.7. Mirrors

Dresser mirrors, wedding mirrors, special events mirrors, and bar mirrors are trendy. Nowadays, laser etched glass mirrors are more prevalent than neon-lighted signs. Laser etched glass mirrors are famous for both indoor and outdoor applications. In this case, unique designs, complex shapes, and logos may increase the product’s value.

4. Best Glass Material for Laser Etching

Typically, you can etch almost all types of ordinary glasses. Although, some glass containing additives such as gold, zinc, or lead may lead to unexpected laser etching. Therefore, you may avoid these types of glass for laser etching. However, in the following, we have discussed the most popular glass materials for laser etching.

Soda-Lime Glass: It is also famous as soda-lime-silica glass. Soda-lime glass is the most common glass type that you may see nearby. These types of glass are typically used for packing beverages, food, or other items.

Silicate Glass: This type of glass is based on silicon dioxide or silica. However, other substances include soda, alumina, and boro site. Besides, silicate glasses are also famous as optical mirrors and fiber optics.

Molded Glass: This type is usually famous for making different glassware products.

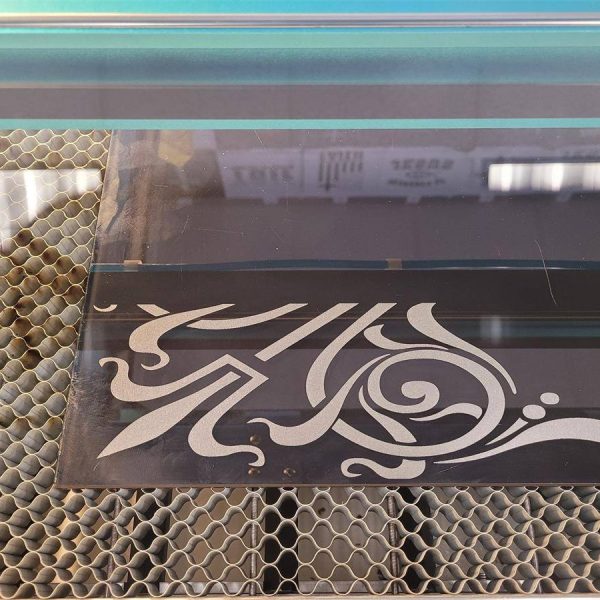

Sheet Glass: These glasses are ideal for making signage, words of invitations, and wedding showcases. Sheet metals are suitable for engraving designs, text, or images.

Mirror Glass: All laser glass etching machines can engrave mirror glass. Usually, the laser beam from the device passes through the first barrier of the glass and etches at the backside.

5. Best Laser Machine for Glass Etching

For laser etching on glass, the Thunder Laser Bolt series stands out with its RF CO₂ laser, delivering the fine beam control needed to mark delicate glass surfaces without cracking or chipping. Compared to traditional DC lasers, the RF tube ensures more stable output at low power, which is essential for etching glass cleanly—especially on detailed logos, texts, or decorative patterns.

The Bolt’s high-speed motion system combined with LightBurn software compatibility lets users fine-tune settings for different types of glass, such as soda-lime or borosilicate, and achieve consistent results across both flat and cylindrical surfaces. Its optional rotary attachment makes etching wine glasses and bottles not only possible but efficient, with minimal setup time.

If your business involves custom glass gifts, trophies, or barware, the Bolt’s accuracy and workflow efficiency can help you scale production while maintaining quality.

6. Expert Advice for Laser Etching on Glass

However, while laser etching mirrors, it is better to engrave on the other side using the inversed design. Choose an ideal rotary attachment for cylindrical or conical shape glasses. Use recommended software from the manufacturers. Above all, if you have any questions, don’t hesitate to contact us. Our team of experts is always waiting to respond. You can also browse our laser glass engraving machines. Our laser machines are world-class, and we satisfied thousands of buyers.

Conclusion

Laser etching on glass combines technology and creativity, allowing you to produce detailed, high-value designs on nearly any type of glass. Whether you’re a hobbyist or a business owner, understanding the right techniques, materials, and machine features will help you achieve better results. Ready to bring your ideas to life? Browse our professional laser glass engraving machines and start crafting your own glass masterpieces today.

FAQs About Glass Laser Etching

Q1. How long does a laser etched mark on glass last?

Laser-etched designs are permanent and do not fade over time. They are resistant to scratching, washing, and UV exposure, making them ideal for long-term use.

Q2. Is laser etching safe for food-contact glassware?

Yes, laser etching is non-toxic and safe for items like wine glasses or tumblers, as it doesn’t involve chemicals or additives. Just ensure the glass is properly cleaned before use.

Q3. Should I use coating or masking for laser etching on glass?

Using a light coating—like a damp paper towel or a thin layer of dish soap—can help reduce micro-fractures and chipping during laser etching. These methods act as a thermal buffer, especially for fragile or low-quality glass. While not always necessary, using masking is a smart choice if you’re aiming for cleaner results or working with thin or uneven glass surfaces.

Q4. Can I laser etch curved or irregular glass surfaces?

Yes, laser etching is possible on curved or irregular-shaped glass using a rotary attachment. This tool rotates cylindrical or conical objects like wine glasses and tumblers during the engraving process, ensuring accurate and consistent results. For highly irregular shapes, precise focus adjustment and testing are recommended to maintain engraving quality.

Q5. How to clean glass properly after laser etching?

To clean glass after laser etching, use a soft cloth with warm water and mild soap. Avoid harsh chemicals or abrasive materials that can scratch the etched surface. For residue left from masking or coatings, rubbing alcohol or diluted vinegar can help dissolve any remaining film without damaging the design.

.png) International

International

United States

United States

Brasil

Brasil

Canada

Canada

Costa Rica

Costa Rica

Česká

Česká

Ελλάδα

Ελλάδα

Polska

Polska

Ireland

Ireland

Portugal

Portugal

Lietuva

Lietuva

Россия

Россия Deutschland

Deutschland

Britain

Britain

Україна

Україна

France

France

Sverige

Sverige

Italia

Italia

Norway

Norway

Denmark

Denmark

Romania

Romania

한국

한국

中国

中国

ประเทศไทย

ประเทศไทย

中国香港

中国香港

Israel

Israel

中國臺灣

中國臺灣

India

India

پاکستان

پاکستان

پශ්රී ලංකා

پශ්රී ලංකා

ジャパン

ジャパン

Australia

Australia

New Zealand

New Zealand

South Africa

South Africa