Laser Engraver

- Home

- >

- Thunder Laser, Your Best Laser Machine Manufacturer

- >

- Laser Engraver

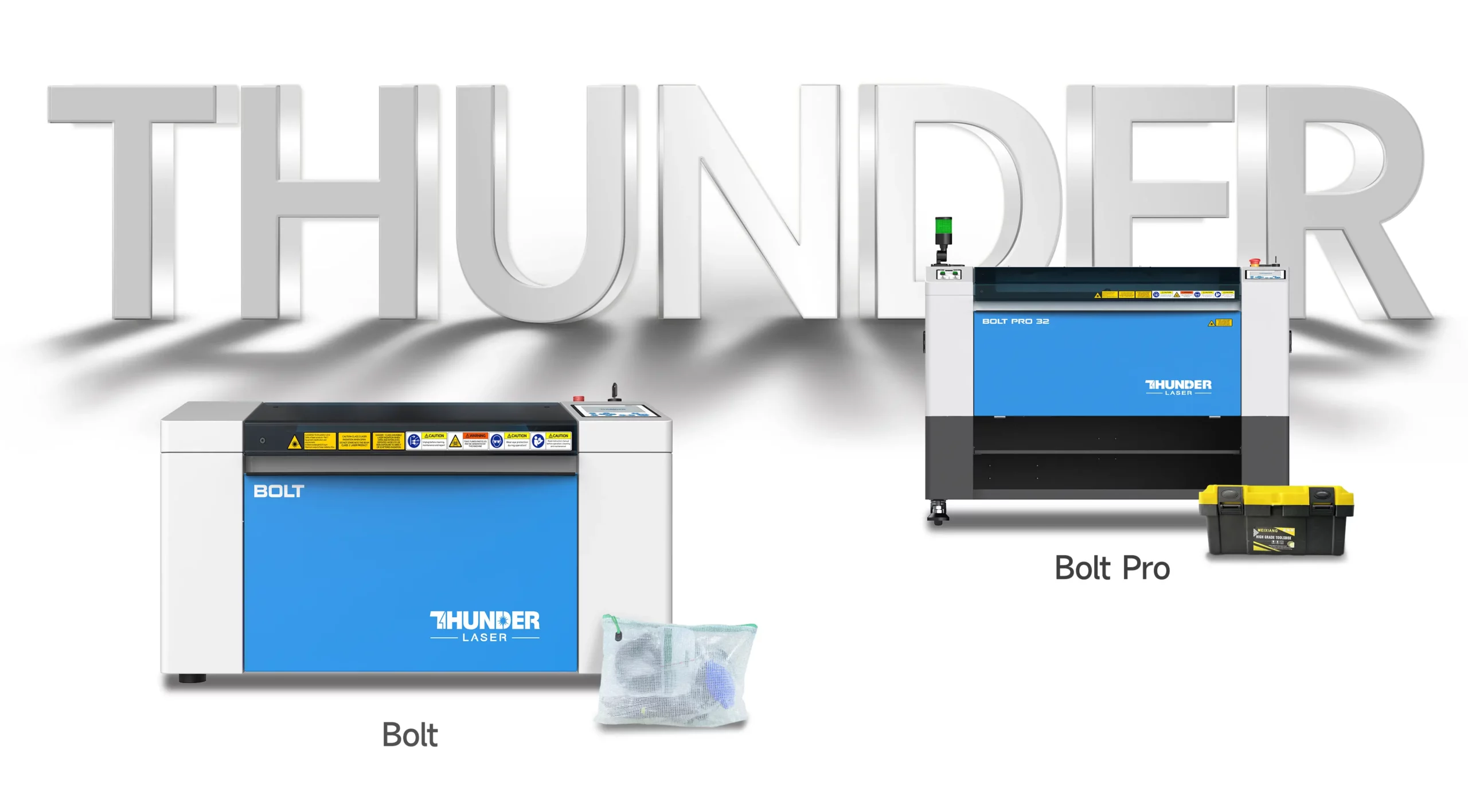

Thunder Bolt Laser Engraving Machine

Laser Type : RF CO2 metal tube type

Application: Cutting and Engraving

Bolt

Bolt Pro

Bolt

Bolt Pro

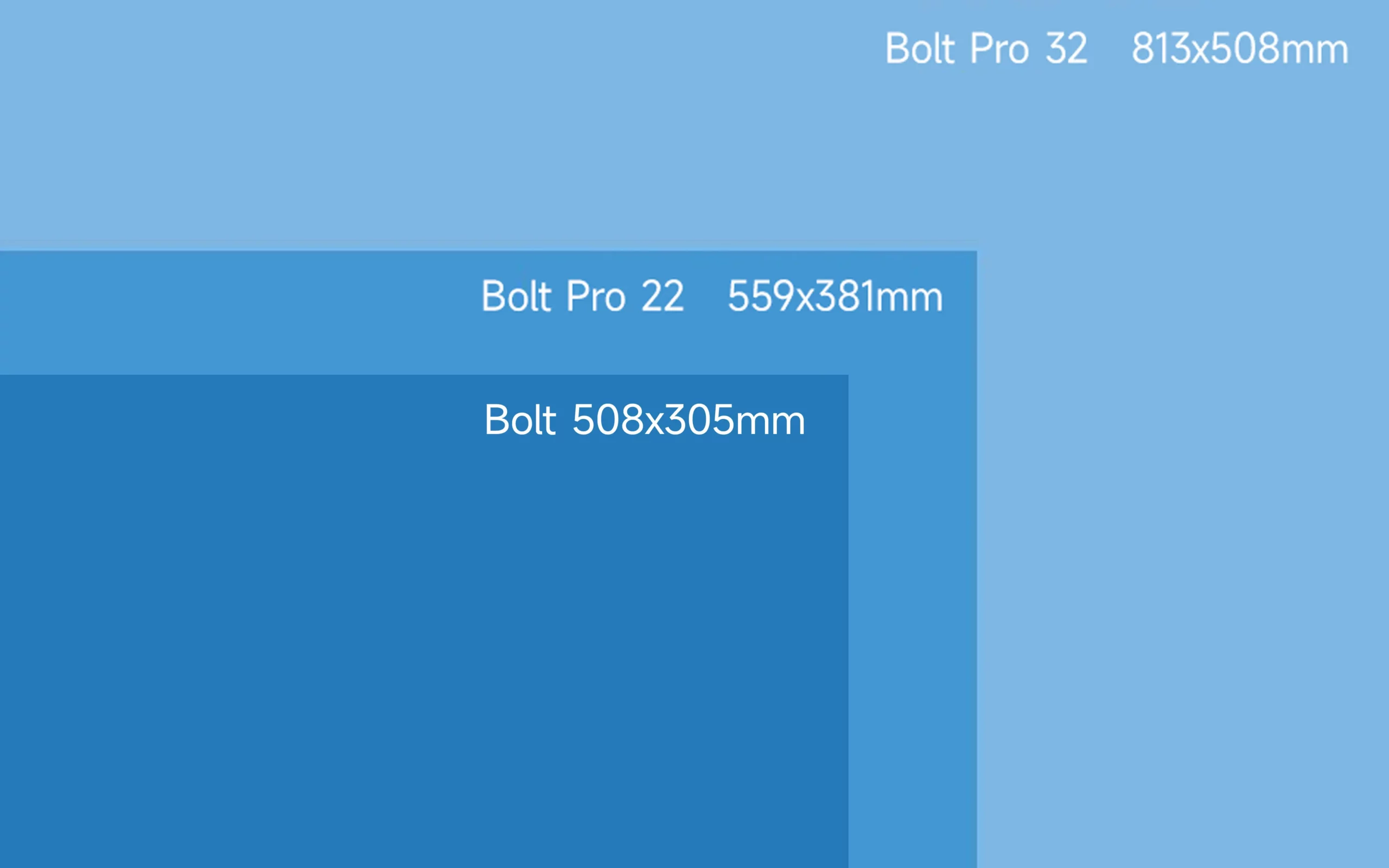

A size that Can support your business

Double Nova speed and Higher accuracy

2000mm/s

How well does it cut?

As well as Nova

The laser cutting quality is mainly determined by the laser beam quality.

Bolt Laser Engraving Machine can generate higher quality lasers than Nova, So you can see :

1、As smooth or neat as Nova

2、Clean

3、Less burrs

Ready to learn more about Upgrades?

Higher precision

more precise and stable laser, which is why lasers 2+ times more precise and stable than Nova.

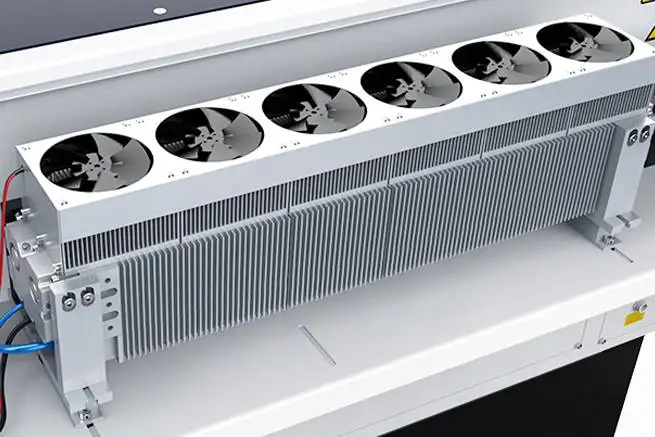

With powerful heat dissipation, no need for a cold water tank.

Blot Laser Engraving Machine’s lifespan, 2-5 times longer, can be recycled indefinitely after refilling CO2 gas.

– The first breakthrough upgrade compared to Nova.

Quicker Speed

Blot Laser Engraving Machine’s speed secret? An international 5-phase open-loop stepper motor and Thunder laser ABS smooth guide rail patent working in harmony.

With 5G acceleration and 80IPS, Blot Laser Engraving Machine races ahead at 2+ times the speed of Nova.

Plus, enjoy low noise and minimal resistance for a seamless experience.

– The second upgrade compared to Nova.

Upgraded Design

Discover the Blot 32 v2.0 enhancements:

1. Elevate your experience with a touch screen panel.

2. Precision meets control with a dual air assist system and pressure detector. ( Blot 32 v1.0)

3. Dust covers for a cleaner workspace and reduced maintenance.

4. Seamless installation with an integrated air pump and suction fan.

– Blot Laser Engraving Machine’s third new upgrade compared to Nova.

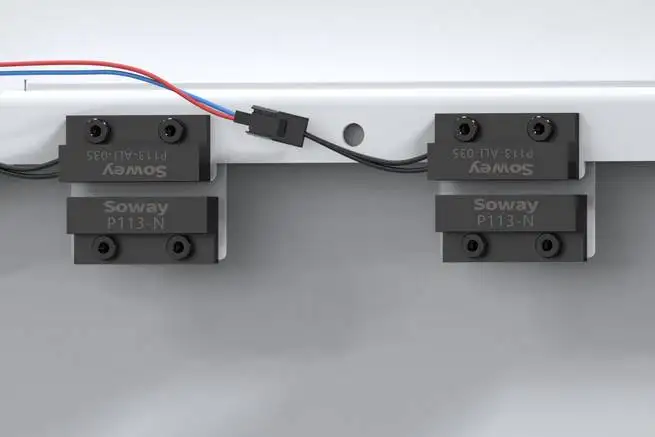

More friendly, Safe

Aligned with Nova’s warning light and emergency stop switch, Blot Laser Engraving Machine meeting CE and FDA safety standards.

Enhanced safety with 8 cover opening protection sensors, automatically halting operations when parts are opened or disassembled, ensuring your safety. ( Blot 32 v2.0)

– The ultimate upgrade from Nova, prioritizing your well-being.

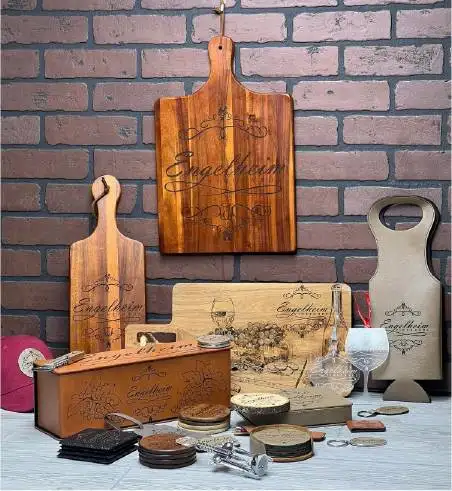

More Daily life Applications,More possibilities...

Broader industry Applications

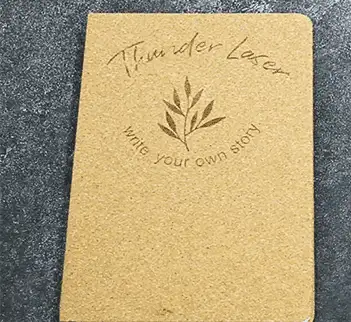

2. Personalize jewelry with custom-carved texts and patterns.

2. Personalize daily essentials – pens, pen holders, notebooks, and beyond.

Clothing industry

2. Master laser engraving patterns or text.

3. Bring complexity to life with intricate patterns and vibrant gradient colors.

2. Streamline logistics with tracking codes—serial numbers, customer data, and more.

- Daily life applications

- Clothing industry

- Jewelry and ornaments

- Education industry

- Manufacturing

- Model production

- Packaging industry

- Medical, automotive

- ...

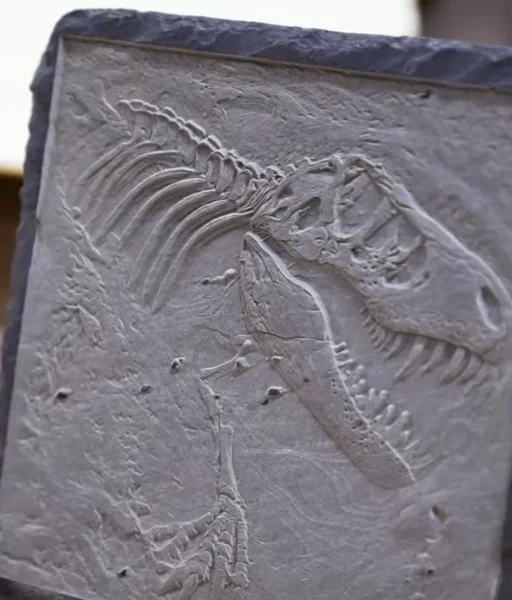

Painting with Light

Ready? Get an Available Status Now

We will be happy to help you all your questions

1.How is laser generated?

The CO2 RF laser shares the principles of CO2 glass tubes, CO2 molecules to undergo chemical reactions to produce laser.

The twist? Just a little different from CO2 glass tubes. CO2 RF tubes leverage high-frequency electric fields to induce multiple energy level shifts, igniting the laser generation process.

2.How does laser work to cause engraving?

Laser engraving and laser cutting are quite similar. It also utilizes a high power density focused laser beam to act on the surface or interior of the material, causing it to vaporize or undergo physical changes, forming the required graphic patterns and ultimately forming carving.

The difference is that laser engraving hardly changes the shape of the material and only does shallow carving or etching.

3.RF CO2 laser vs glass CO2 laser?

These advantages make CO2 RF metal laser engraver machine is very suitable for industrial continuous production.

1. Quality beyond compare—over three times finer than glass tubes, ideal for high-definition carving like detailed portraits.

2. Precision comes at a cost: RF laser tubes are pricier, yet offer unmatched precision in carving. While cutting thickness may be limited compared to CO2 laser machines, the advantage lies in high-precision detail work. CO2 glass tubes shine in cutting thicker materials with 100w+ power.

3. Longevity matters: CO2 RF metal laser tubes boast a lifespan 2-5 times longer than CO2 glass tubes, translating to lower maintenance costs, tube reusability, and zero replacements needed.

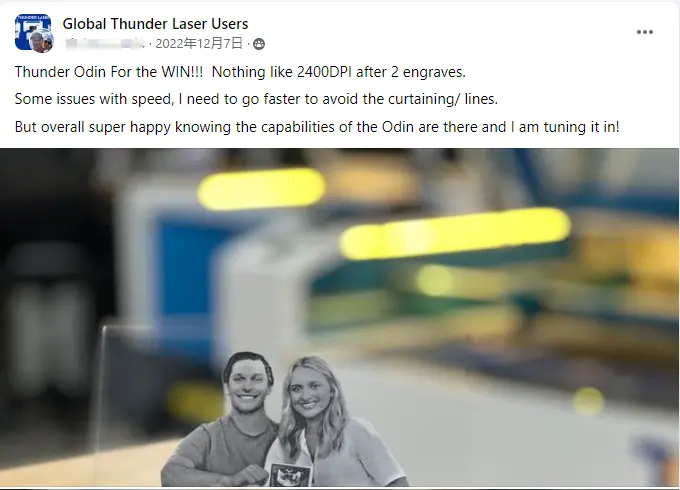

4.About our Customers Reviews

Powerful Laser Software Support

Explore Thunder Laser Engraver in Depth

RF metal laser source

The RF metal lasers are designed to operate without high voltage or water cooling. This makes RF metal lasers inherently safer to operate in almost any environment. RF metal lasers are designed to be durable, provide the highest performance with high laser beam quality, offer indefinite service life, and help assure operator safety. The price is more expensive than DC glass tube, but they have a longer lifespan of up to approximately 10,000hours.

New Auto focus

In order to achieve the best cutting result by wood laser cutting machine, we will make the laser beam focus when it contact the material on laser cutter engraver, and the smaller laser beam, the better performance. Auto focus function can move up and down the working table to make sure the most proper distance between the material and the focal lens.

Dual Air-Assist System

There're 2 modes for air assist. Cut and Engrave. The 2 air solenoids are controlled with the smart board. There are also 2 needle valves mounted on the front left panel so you can adjust the flow for each mode as well as momentary push buttons to test the flow. When you press a button the corresponding stage activates for 10 seconds. So now you can define high(Cut) or low(Engrave) air assist by toggling the air assist function in each layer. With air OFF you get the engrave mode automatically. It offer ON and OFF in the drop down to CUT and Engrave in the current version (this is specific to the Thunder Laser version of RDWorks). All you need to remember when applying layer settings is that air assist OFF will activate the Engrave stage and air assist ON will activate the Cut stage. This also works on Lightburn software, for engraving just toggle air assist off in the cut settings in lightburn. For cutting, toggle air assist ON and it will choose the cut air stage.

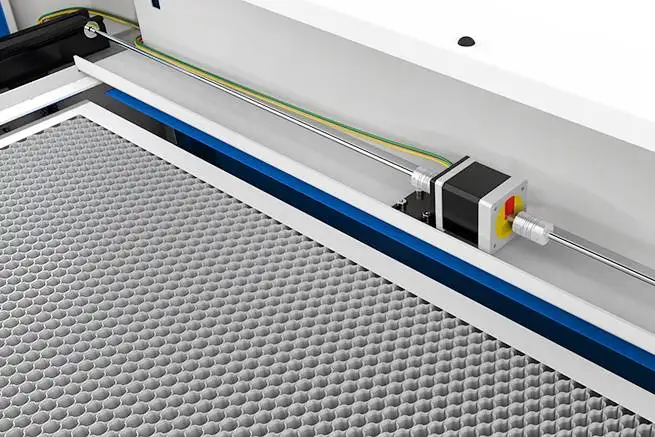

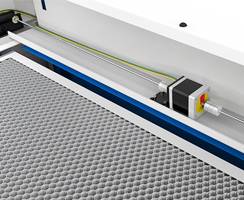

Smoother guide Rail

This new guide Rail was new developed by Thunder Laser engineers with patent right. It matches the new Oriental motor system very well. Less resistance and low noise,that’s the most important factor why Odin series could reach 2000mm/s speed.

New Upper & Lower Vent

New feature for Odin series with Upper and Lower exhaust ventilations design, to remove the heated and burned smoke from the material surface timely while engraving and cutting.

High Speed Motor

The Odin series laser engraver is with high speed and high resolution motor system imported from Japanese ORIENTAL. The 5-phase open-loop stepper motor for X-axis offers balanced performance enhanced by high torque, low vibration and low noise, it turns out to be high efficiency with 3G acceleration and 80IPS speed, providing a super-fast engraving in the industry.

| Laser System | Bolt | Bolt Plus | Bolt Pro 22 | Bolt Pro 32 | |

Laser Tube Wattage |

30 Watt | 30 Watt | 30 Watt | 55 Watt (Coherent) | |

Working Area |

508 x 305 mm (20″ x 12″) | 559 x 381 mm (22″ x 15″) | 813 x 508 mm (32″ x 20″) | ||

Table Size |

557 x 357 mm (21.9″ x 14″) | 660 x 453 mm (25.9″ x 17.8″) | 914 x 580 mm (35.9″ x 22.8″) | ||

Max Part Size (W x L x H) |

515 x 313 x 110 mm (20.3″ x 12.3″ x 4.3″) | 600 x 413 x 183 mm (23.6″ x 16.2″ x 7.2″) | 854 x 540 x 183 mm (33.6″ x 21.2″ x 7.2″) | ||

Dimensions (W x D x H) |

941 x 724 x 498 mm (37″ x 28.5″ x 19.6″) | 1050 x 852 x 1020 mm (41.3″ x 33.5″ x 40.2″) | 1304 x 980 x 1020 mm (51.3″ x 38.6″ x 41.2″) | ||

Laser Type |

Radio Frequency Laser Tube | ||||

Cooling |

Air Cooled | ||||

Maximum Speed |

1000 MM/S | 1500 MM/S | 2000 MM/S | ||

| Maximum machining size at 1000 speed – lightweight laser head | / | / | 529 x 381 mm (20.8″ x 15″) | 783 x 508 mm (30.8″ x 20″) | |

| Maximum machining size at 2000 speed – lightweight laser head | / | / | 461 x 381 mm (18″ x 15″) | 715 x 508 mm (28″ x 20″) | |

Speed and Power Control |

Computer or manually controlled speed and power from 0-100%. Vector color mapping sets speed and power settings using RGB color mapping. | ||||

Operating Modes |

Optimized raster, vector, and combined mode | ||||

Resolution (DPI) |

User controlled from 100 to 1000 DPI (standard laser head) | ||||

Computer Interface |

Ethernet and USB Connection | ||||

Compatible Operating Systems |

Windows, Mac, and Linux (Mac and Linux with LightBurn Software) | ||||

Buffer Memory |

1GB Standard | ||||

Display Panel |

3.5″ LCD panel showing current file, total working time, laser power, speed, etc… | ||||

Electrical Requirements |

110 to 240 volts, 50 or 60 Hz, single phase | ||||

Z-Axis Height |

110 mm (4.3″) | 185 mm (7.3″) | 185 mm (7.3″) | ||

Net Weight |

77 kg (169.7 lbs) | 78 kg (171.9 lbs) | 90 kg (198.4 lbs) | 233 kg (513.6 lbs) | |

Motion Control System |

High-Speed Stepper Motors | ||||

Speed and Power Control (engraving depth) |

Computer or manually controlled speed and power from 0-100%. Vector color mapping sets speed and power settings using RGB color mapping. | ||||

Ventilation System |

Integral exhaust fan. There is 1 output port in diameter in the rear of the case: Bolt pro 22 | bolt pro 32: 155 mm (6.1″) Bolt | Bolt plus: 100mm (3.9″) |

||||

Workpiece Table |

Honeycomb table | ||||

Max. Table Load |

10 kg (22 lbs) | 20 kg (44 lbs) | |||

| Material | Engrave | Cut | Material | Engrave | Cut |

| Wood | √ | √ | Rubber | √ | √ |

| Acrylic | √ | √ | Wood Veneer | √ | √ |

| Delrin | √ | √ | Fiberglass | √ | √ |

| Cloth | √ | √ | Plastic | √ | √ |

| Leather | √ | √ | Cork | √ | √ |

| Mat Board | √ | √ | Corian | √ | √ |

| Melamine | √ | √ | Twill | √ | √ |

| Paper | √ | √ | Anodized Aluminum | √ | × |

| Mylar | √ | √ | Painted Metals | √ | × |

| Pressboard | √ | √ | Tile | √ | × |

| Glass | √ | × | Stainless Steel | * | × |

| Coated Metals | √ | × | Brass | * | × |

| Ceramics | √ | × | Titanium | * | × |

| Marble | √ | × | Bare Metal | * | × |

Better Work with Optional Accessories

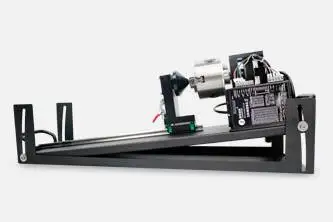

Rotary Axis For Desktop Bolt

Rotary Axis for Bolt Pro

Air compressor

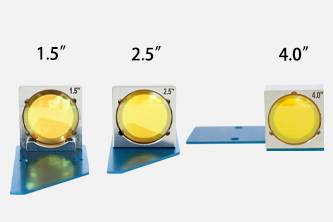

Optional Lenses

Lightburn Software

Lightburn Cam Kits

.png) International

International

United States

United States

Brasil

Brasil

Canada

Canada

Costa Rica

Costa Rica

Česká

Česká

Ελλάδα

Ελλάδα

Polska

Polska

Ireland

Ireland

Portugal

Portugal

Lietuva

Lietuva

Россия

Россия Deutschland

Deutschland

Britain

Britain

Україна

Україна

France

France

Sverige

Sverige

Italia

Italia

Norway

Norway

Denmark

Denmark

Romania

Romania

한국

한국

中国

中国

ประเทศไทย

ประเทศไทย

中国香港

中国香港

Israel

Israel

中國臺灣

中國臺灣

India

India

پاکستان

پاکستان

پශ්රී ලංකා

پශ්රී ලංකා

ジャパン

ジャパン

Australia

Australia

New Zealand

New Zealand

South Africa

South Africa