Laser Marker

- Home

- >

- Thunder Laser, Your Best Laser Machine Manufacturer

- >

- Laser Marker

Aurora Laser Marking Machine

Laser Type : Fiber laser, UV laser

Application: Marking and Engraving

Fiber Laser Materials : Multiple materials including metal, abs dual color plastic, aluminum oxide, spray metal etc.

The Thunder Laser Marker Aurora series boasts a uniform and appealing design across its product range. Focus on the laser type, speed, and power when choosing to achieve varied needs.

Aurora 8, a member of the Aurora Laser Marking Machine family, achieves a maximum speed of 7000mm/s. Ideal for addressing a wide array of fiber laser marking metal requirements, it stands out as a versatile solution.

Aurora 8 UV, ’s speed is the same as Aurora 8. While its speed may not be the highest, it excels in the precision laser marking and carving of both metals and non-metals.

Introducing the Aurora 8 PRO, an upgraded iteration of the Aurora Laser Marking Machine. This fiber laser marking machine raises efficiency with a remarkable speed of up to 10000mm/s.

Desktop size but can support your business

Aurora Laser Marking Machine, a powerful desktop fiber laser engraver. It can opens the door to launching your career from the comfort of your home or within compact workspaces.

Notably smaller than Thunder Laser Nova and Odin, Aurora Laser Marking Machine offers unparalleled flexibility, allowing you to effortlessly switch and optimize your work location as needed.

Super speed and precision

Aurora Laser Marking Machine’s exceptional performance is attributed to a combination of high-quality components. Including a premium laser source, advanced Galvanometer and field mirror, and rigorous dimming testing protocols.

Two types of powerful lasers, fiber or UV. It’s adjustable pulses spanning from 2 to 500ns. Ensures your fiber laser engraving products exhibit clarity and precision, meeting the highest standards.

A galvanometer composed of two mirrors can quickly and accurately control the refractive angle of light. That’s why you can quickly and finely laser engrave metal with Aurora Laser Marking Machine.

Over 5 rigorous dimming and testing procedures, with an error margin of less than 0.5mm.

What have Our Customers like you Create

with Aurora Laser Marking Machine

laser engraving slate stone

laser marking metal jewelry

laser marking leather

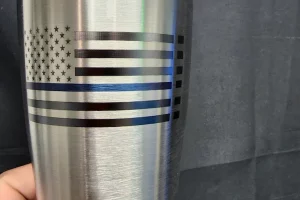

laser engraving Tumbler

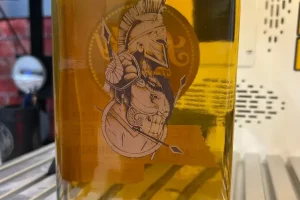

laser engraving glass bottle

Easy to use

- Laser head autofocus

- Light Camera

First step: Power on and Auto focus.

Next step: Visualize to design through the camera.

Last step: Protect your eyes as the protective cover automatically lowers into place. Start your Aurora Laser Marking Machine now!

Experience simplicity at every step!

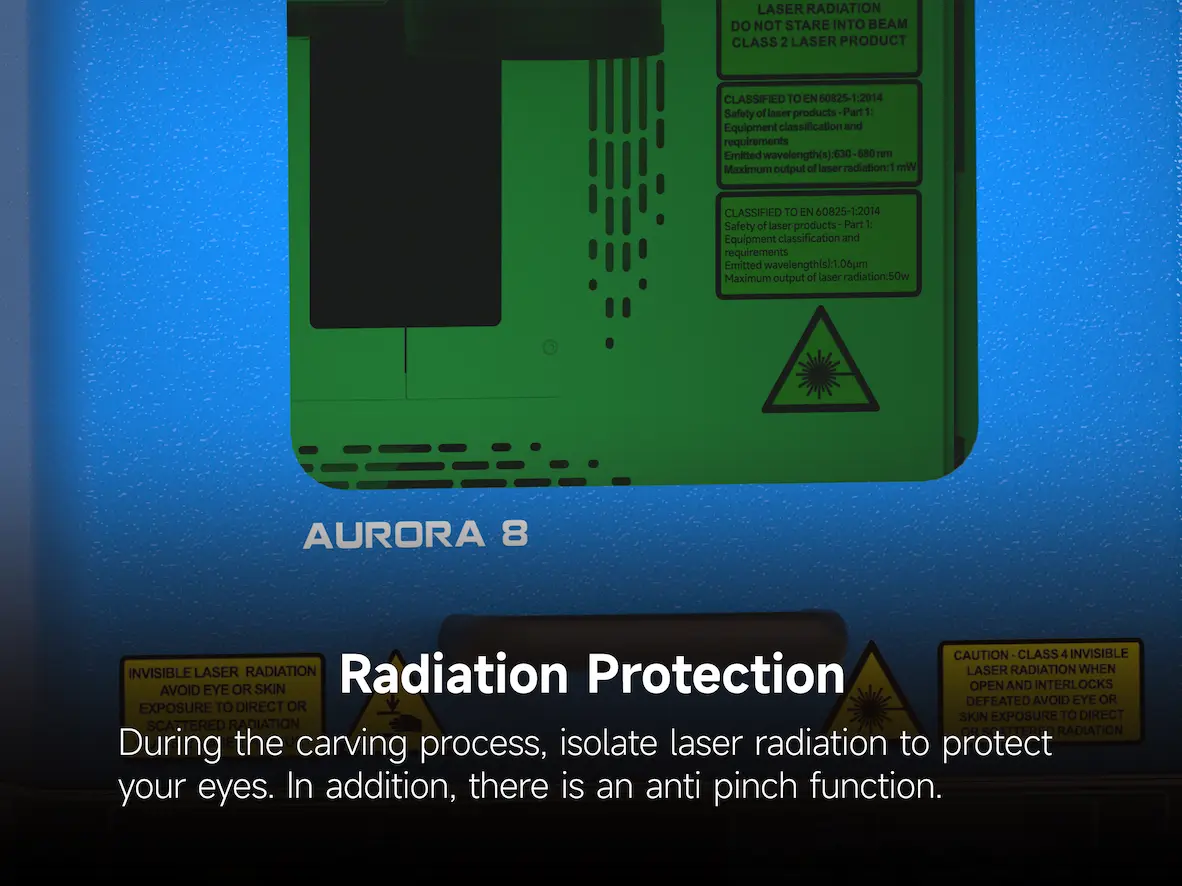

Ensure your safety

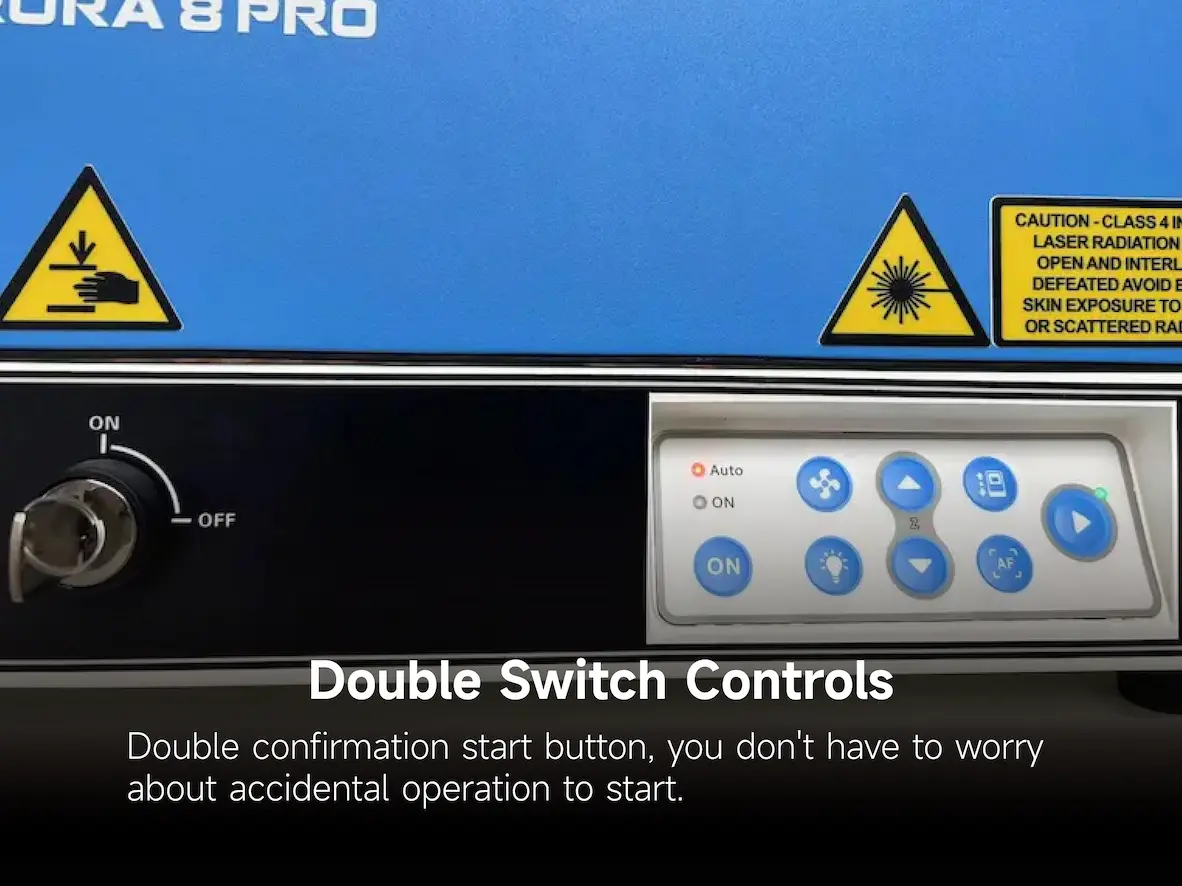

- Double switch controls

- Radiation protection

- Safety warning light

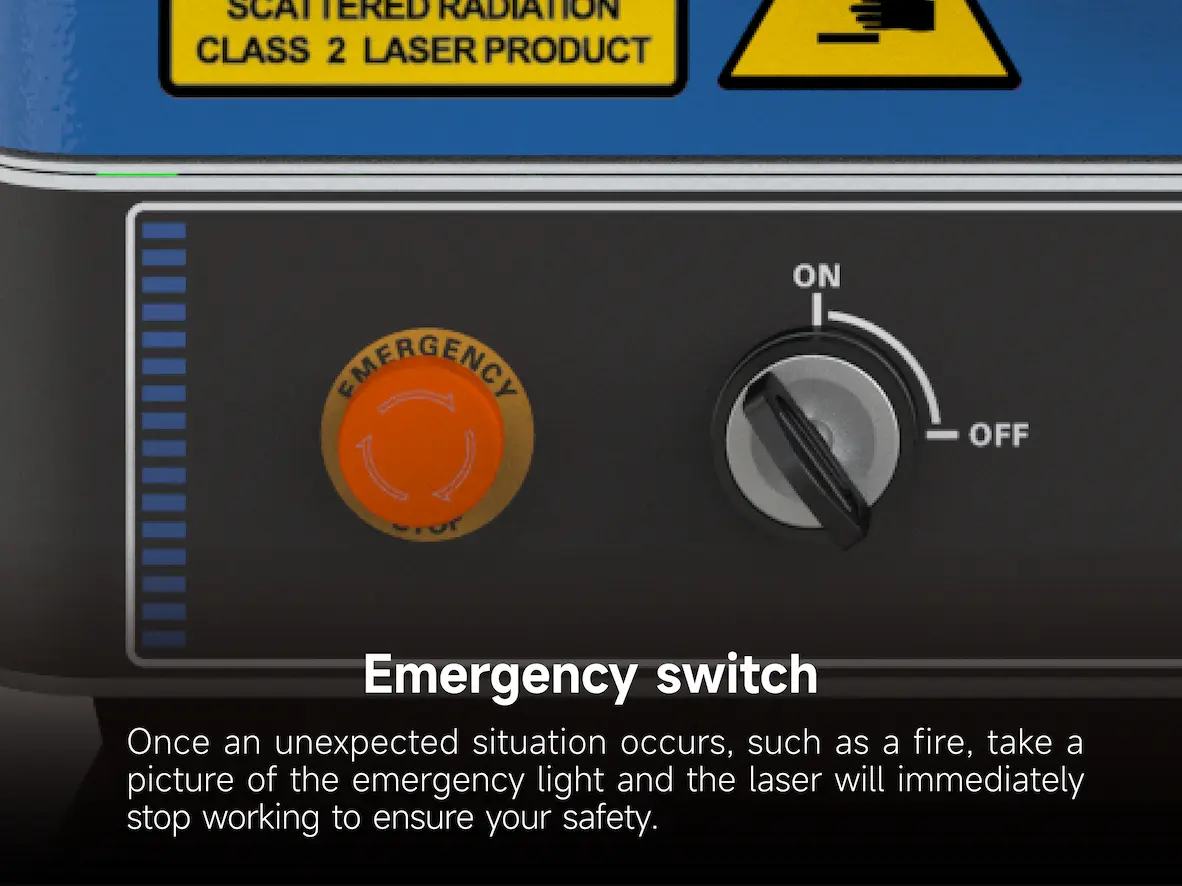

- Emergency switch

Rest easy with these thoughtful configurations. Upon completing your work, a warning light ensures you’re promptly alerted. For added peace of mind, you have the flexibility to stop the Aurora Laser Marking Machine at any moment, prioritizing your safety above all else.

We will be happy to help you all your questions

1.How is fiber laser generated?

In the world of laser machines, internal substances undergo chemical reactions, resulting in particle inversion and laser generation.

What sets fiber laser machines apart is their use of optical fibers to transmit laser. The laser gracefully traverses the optical fiber, culminating in a stable and reliable laser output.

2.How does laser work to cause marking?

Much like laser engraving, this process employs a a high-energy-density laser beam to irradiate material surfaces. Light energy swiftly transforms into heat energy, inducing rapid surface material evaporation and enabling precise text and graphics engraving.

Diverging from engraving, laser marking etches with a shallower impact, preserving the material’s shape. Notably, beyond evaporation, lasers engage in chemical reactions with the material surface, altering color and crafting intricate images and text.

Think about it, laser marking creates intricate patterns that even turn into another color, how interesting it is.

3.Fiber laser engraving vs CO2 laser engraving?

The Fiber laser machine harnesses the stability of fiber lasers, surpassing CO2 lasers in quality and delivering precise marking effects.

Ideal for marking most metals and select non-metallic materials, its desktop design caters to family-scale operations, ensuring convenient use for both personal and business needs.

In contrast, CO2 laser machines, equipped with CO2 lasers, excel in carving non-metallic materials but lack metal carving capabilities.

Tailored for mass production and large-scale projects, CO2 machines boast expansive work areas and high power, catering to the demands of extensive carving and manufacturing.

4.UV laser vs Fiber laser

The UV laser, with its cold light source, excels in labeling most metals and non-metals, making it versatile across all materials.

In contrast, the Fiber laser, while capable of marking some non-metals, has a lifespan of only half that of UV. For precision marking and carving across a broad spectrum of metals and non-metals, the UV laser stands as the undisputed king.

Powerful Laser Software Support

Explore Thunder Laser Marker in Depth

Protective windows

Thunder Laser prioritizes eye safety, reducing any risk of eyesight damage with our patented fully enclosed protective cover made with lasting materials. Additionally, our marking lasers come with intelligent control for accurate aim and improved user safety, reducing glare and control laser volume.

Laser auto focus

Applying geometric optics on our laser marking machine ensures quicker autofocus performance, resulting in fast labelling that leaves no room for errors. We fire a short light burst that travels towards the sensor, which has an accurate software to measure the time it reaches the target object and returns. Through contrast testing, our laser has been proven a faster autofocus speed.

High speed Scanhead

Our laser marker adopt a dynamic magnetic structure for the galvanometer motor. This gives our lasers excellent stability, high positioning accuracy, fast marking speed and high interference resistance. With an engraving speed of 8,000 mm/s, THUNDER laser surpasses our competitors. An innovative motion system and a revolutionary drive concept. What does this mean for your users? The most efficient production, the highest throughput and thus the greatest profitability with impeccable quality.

MOPA laser source

Variable pulse durations are possible with our MOPA lasers, and long or short pulses can be gradually adjusted between 2 and 500ns (60w). The parameters of our marking laser, from pulse frequency to energy, can be adjusted independently during use, resulting in energy conservation and marking flexibility.

Fiber System |

AURORA 8 | Fiber | AURORA 8 | UV | AURORA 8 PRO | AURORA 8 PRO | MOPA |

Laser type |

FIBER LASER | UV LASER | FIBER LASER | FIBER LASER |

Marking area |

4.3″×4.3″/110×110mm | 5.9″×5.9″/150×150mm | ||

Max work Height |

7.6″/195mm | 5.5″/140mm | ||

Max marking speed |

7m/sec, 700cps | 10m/sec, 1000cps | ||

Z-axis |

Motorized Z-axis, 16.9″/430mm | |||

Table |

Alumina table, 14.7″×11.3″/375×288mm | |||

Net weight |

89.3kgs/196lbs | 92.5kgs/203lbs | 93.7kgs/206lbs | |

Housing dimensions(W*D*H) |

29.7″×16.9″×31.4″/755mm×430mm×799mm (UV Series:30.3″×16.9″×31.4″/770mm×430mm×799mm) |

|||

Frequency |

20W | 5W | 50W | 20W, 60W, 100W |

| 20-60kHz | 20-150kHz | 50-100kHz | 1-4000kHz | |

Pulse width |

110ns | 2-500ns | ||

Cooling |

Air cooled | |||

Red dot pointer |

Laser Power<1mW, 630-680nm | |||

Software |

EzCad2 | EzCad3 | ||

Optional F-theta lenses |

5.9″×5.9″/150×150mm | 7.9″×7.9″/200×200mm | 4.3″×4.3″/110×110mm | 7.9″×7.9″/200×200mm |

| Material | Applicable | Material | Applicable |

| Metallic Materials | √ | Carbon Steel | √ |

| Rigid Plastics | √ | Aluminum | √ |

| Hardware Tools | √ | Iron | √ |

| Industrial Accessories | √ | Steel | √ |

| Stainless Steel | √ | Most of Materials (UV laser) | √ |

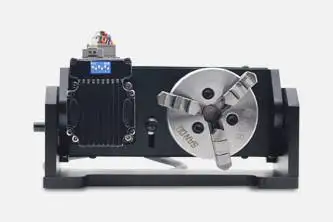

Better Work with Fiber Laser Accessories

Rotary Axis

Optional Lens

Aurora Videos You can't miss

Laser engraving metal rings with chuck rotary of Aurora Laser Marking Machine

Thunder Aurora UV Multi Color on a Gold Business Card.

Thunder Aurora UV-5W vs. JDS plastic cup

.png) International

International

United States

United States

Brasil

Brasil

Canada

Canada

Costa Rica

Costa Rica

Česká

Česká

Ελλάδα

Ελλάδα

Polska

Polska

Ireland

Ireland

Portugal

Portugal

Lietuva

Lietuva

Россия

Россия Deutschland

Deutschland

Britain

Britain

Україна

Україна

France

France

Sverige

Sverige

Italia

Italia

Norway

Norway

Denmark

Denmark

Romania

Romania

한국

한국

中国

中国

ประเทศไทย

ประเทศไทย

中国香港

中国香港

Israel

Israel

中國臺灣

中國臺灣

India

India

پاکستان

پاکستان

پශ්රී ලංකා

پශ්රී ලංකා

ジャパン

ジャパン

Australia

Australia

New Zealand

New Zealand

South Africa

South Africa