Laser Manufacturing

- Home

- >

- Laser Manufacturing

Discover How We Build Laser

From Parts to Product

THUNDER LASER adhere to global production standards and strict quality control throughout the production. From component procurement to final inspection before shipment, we ensure your laser equipment meets your expectations.

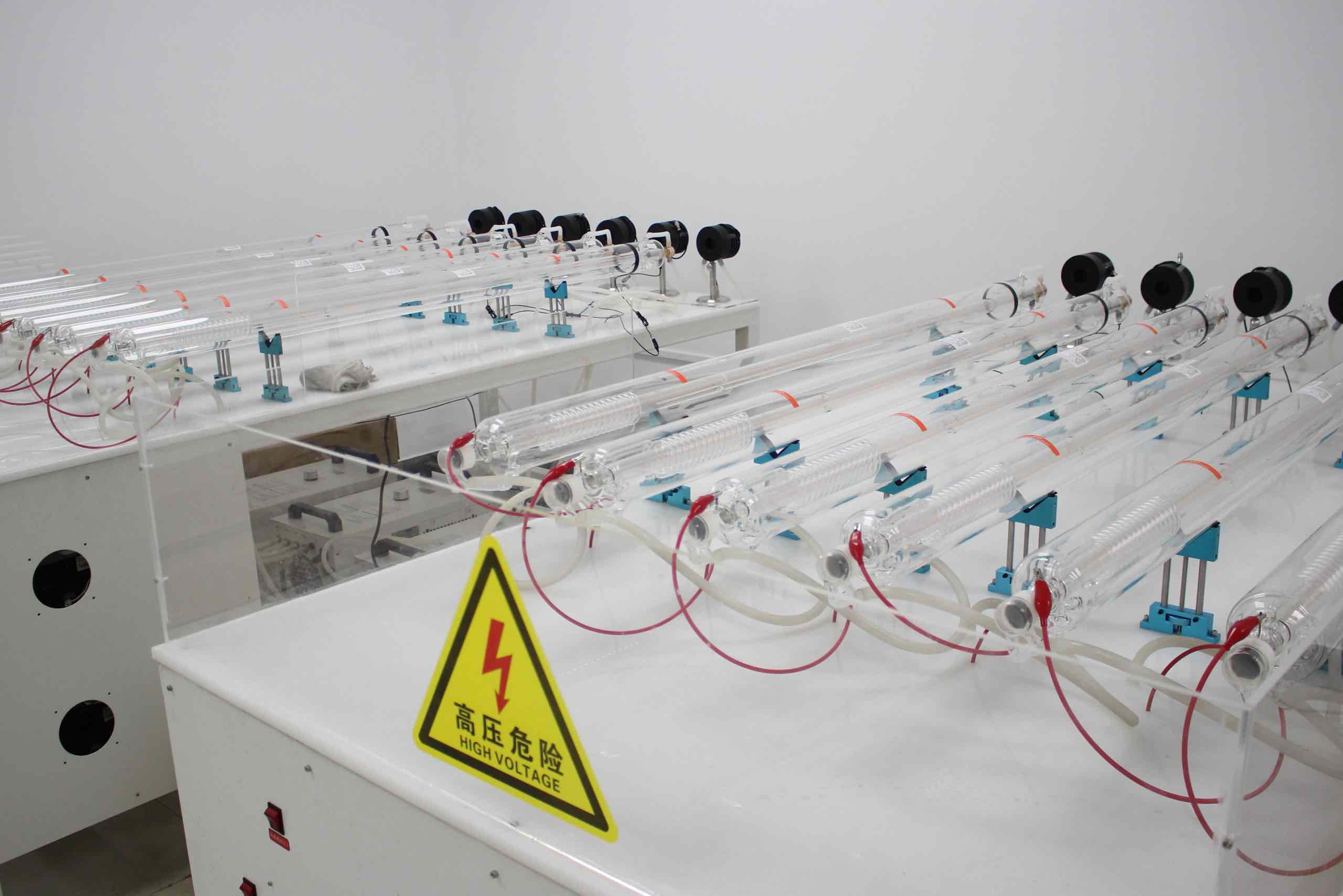

Excellence Starts with Parts

The key factor to the high-grade performance and durability of our laser equipment comes from our strict screening process for our suppliers and the rigorous incoming material tests. To further guarantee the quality of our laser machines, we have our self-developed hardware that checks on the performance and functionality of components.

Incoming Test for

- Housing >

- Mechanical Parts >

- Laser Tube & Power >

- Printed Cir Board >

- Accessories >

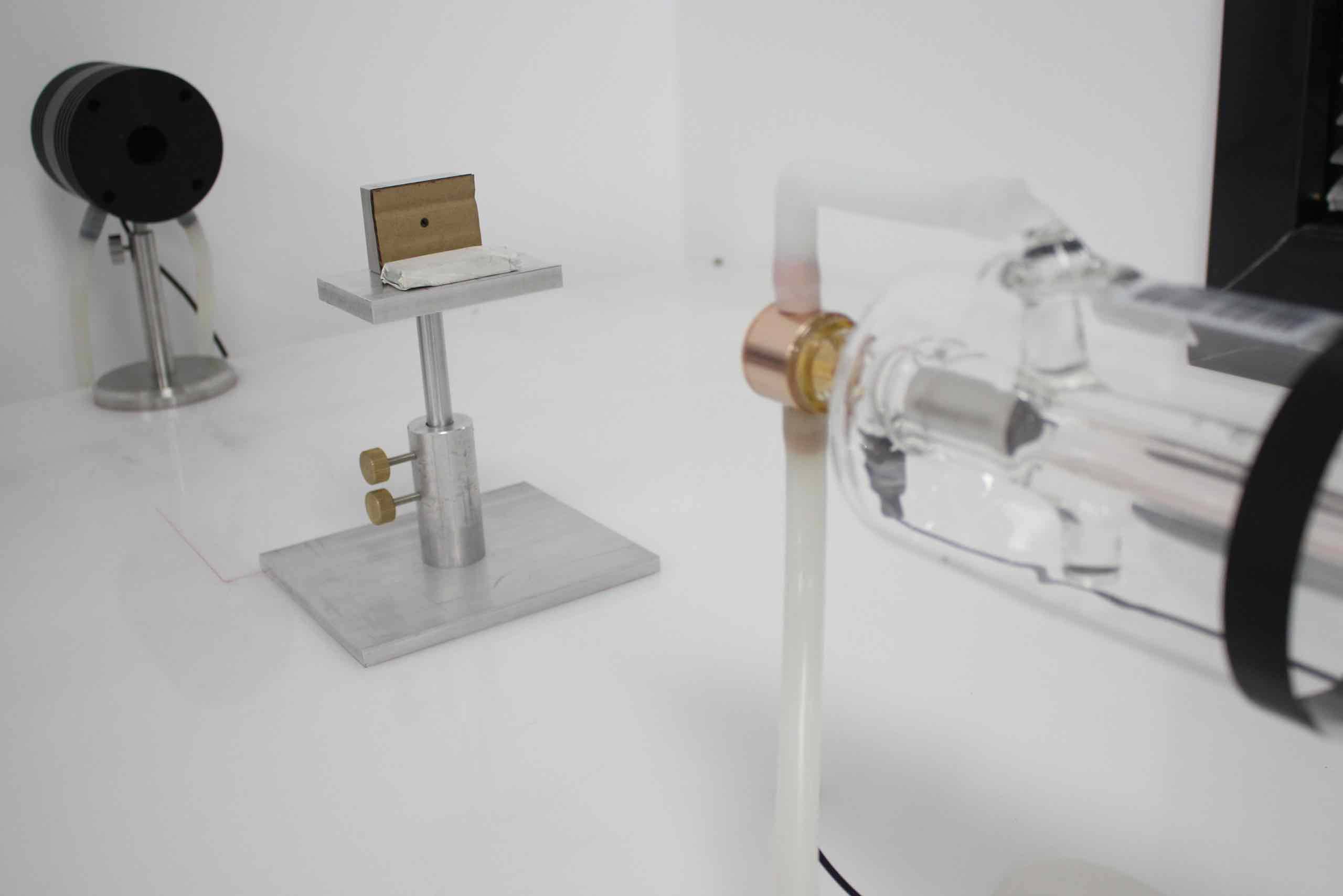

Our inspectors test the light spot and light cone with thermal paper and acrylic at a distance of 0.8-1.5 meters. This is to ensure that the spot shape and light cone depth are correct and that there is no light leakage.

Using the Positive Point Atomic Mini-pro offline downloader, we download a program to the printed cir board. This allows us to quickly test the board for proper operation without going through the machine.

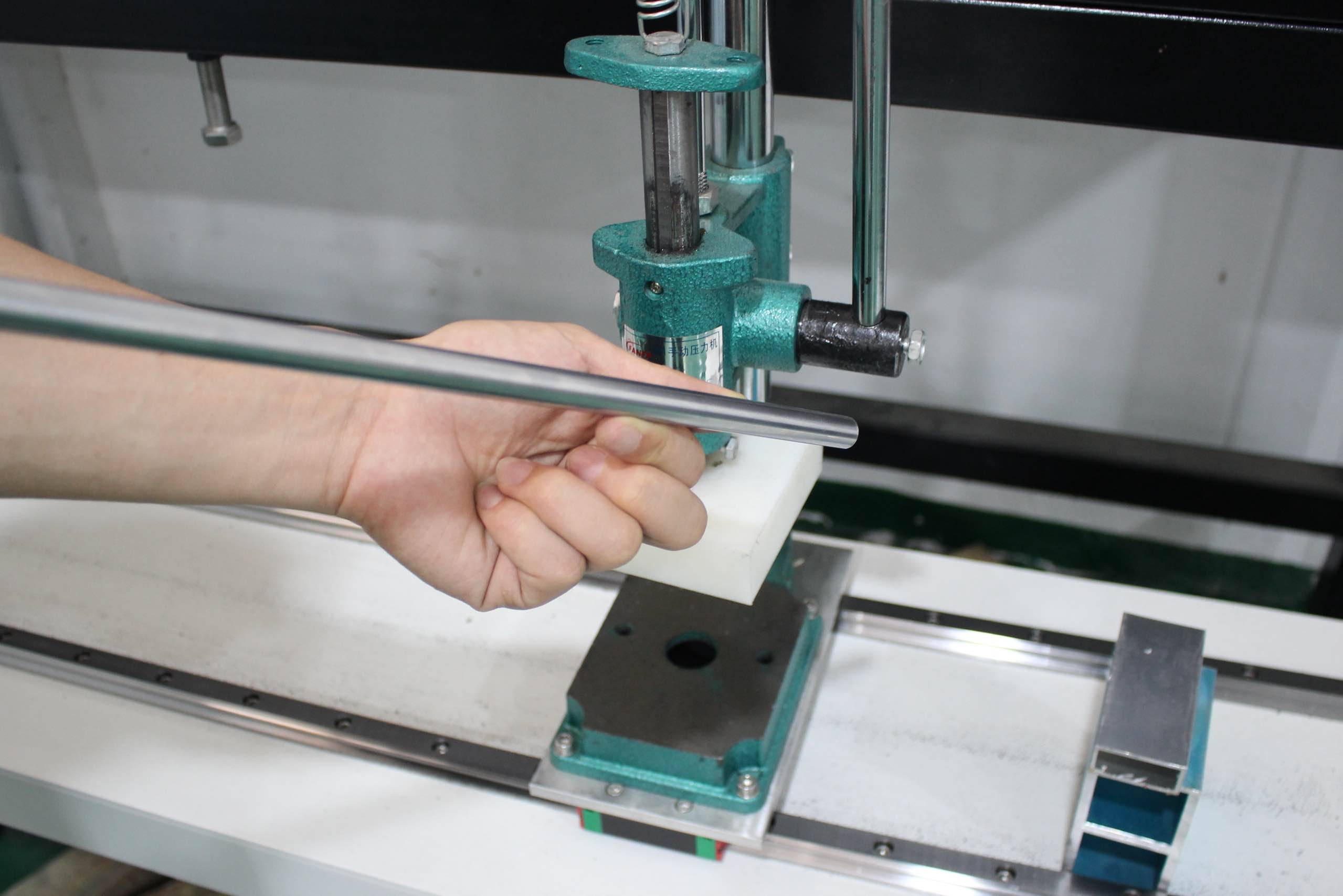

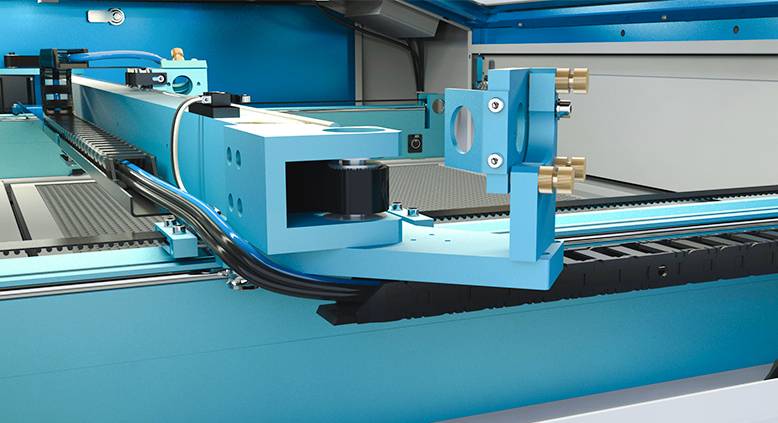

Skilled & Meticulous

Mechanical Assembly

THUNDER LASER’s skilled workers own more than five years of assembly experience and specialized assembly skills. Each of our team members follows our established production standard documentation to install components, ensuring consistency in the quality of our laser equipment.

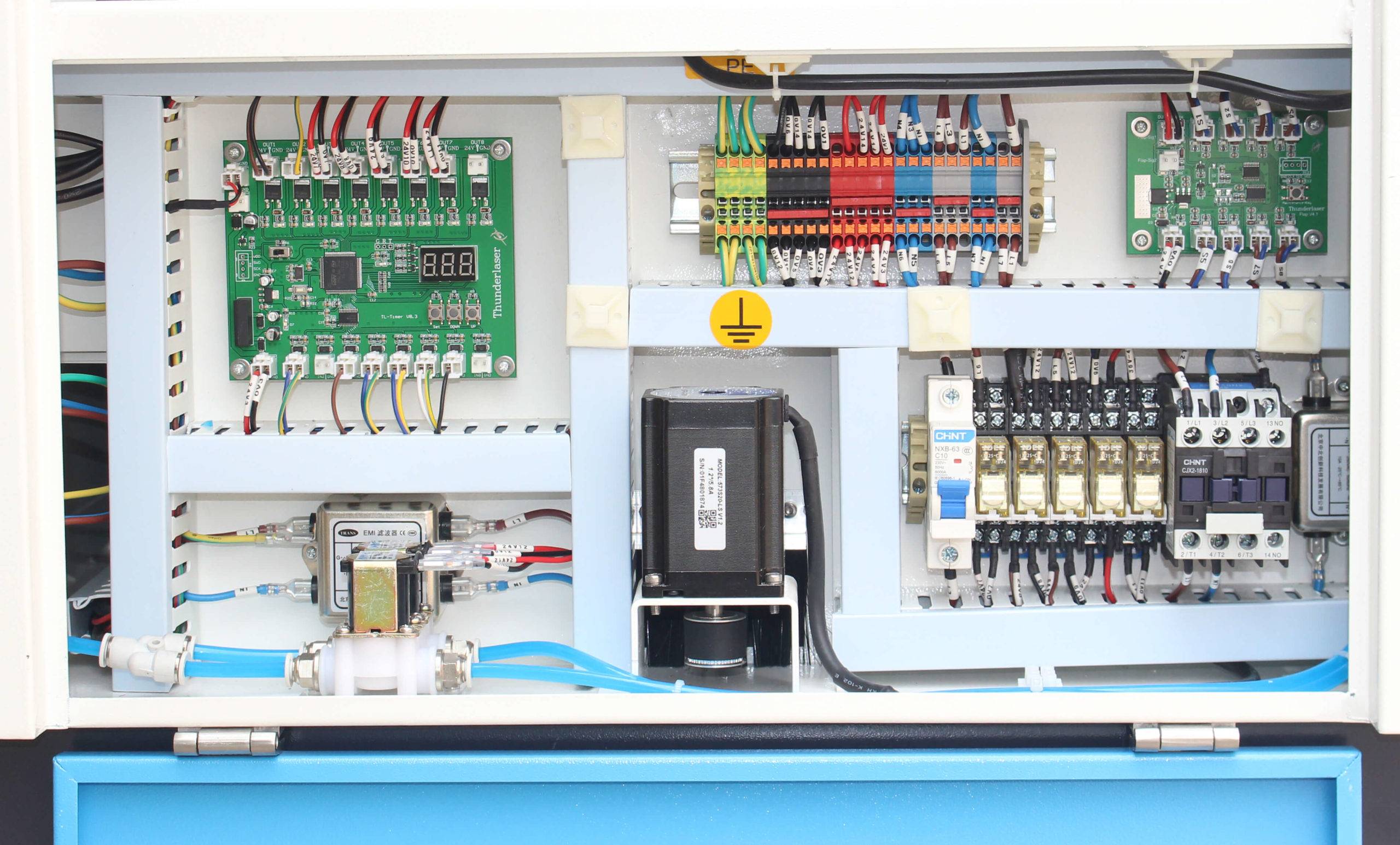

Quick & Waste-free

Circuit Installation

High-grade wire cutting machines and crimping machines can process the wires for our laser equipment with minimized wastage. The tools and our skillful workers ensure optimized connections between all components of our laser machines.

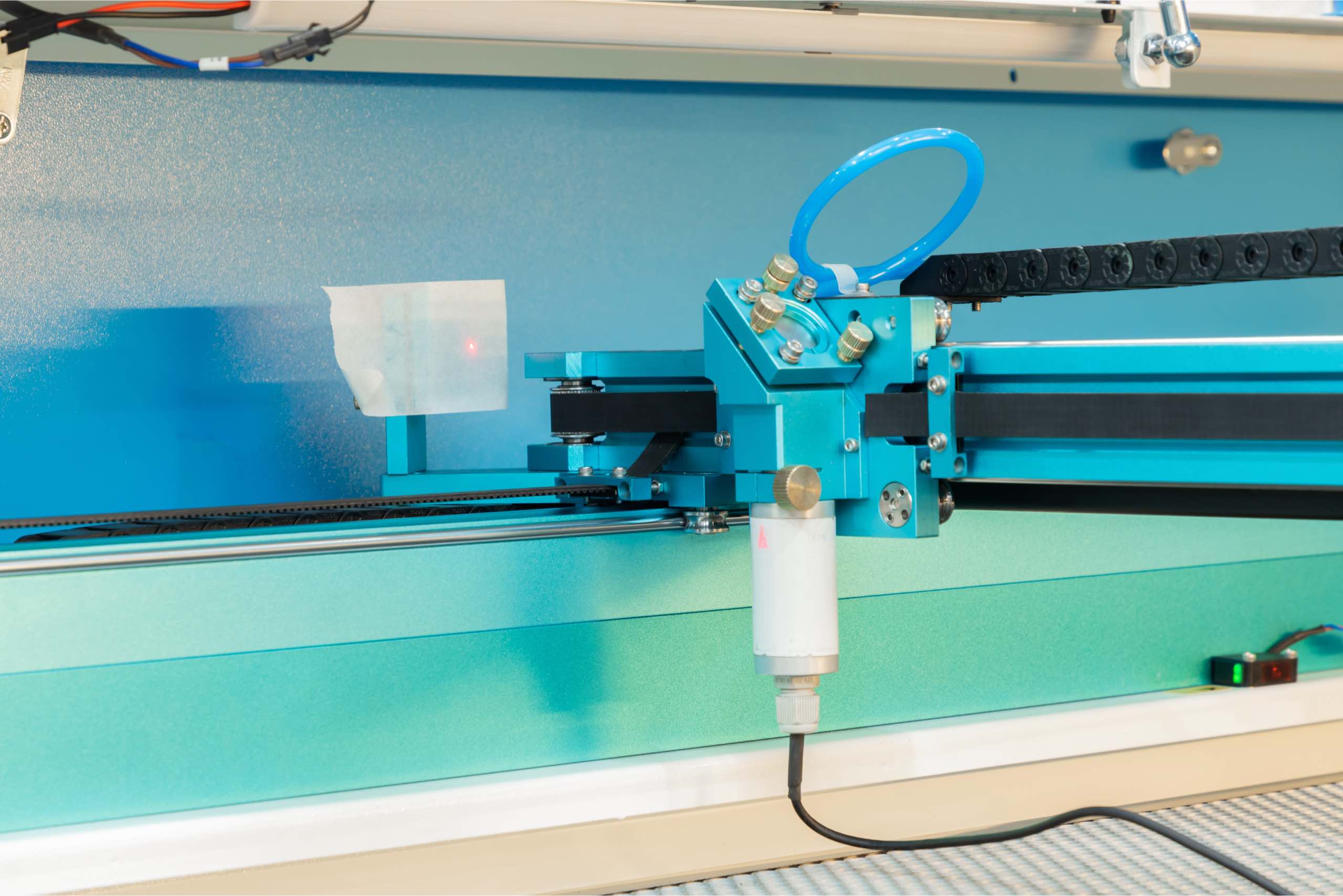

With Patented Tool

Optical Path Debugging

Using our red dimming tool in adjusting the red light output, we can fine-tune the light ray of our laser machines to be more accurate and quicker. We also utilize our acrylic dimming tool to set the laser light path that further improves the performance and precision of our equipment.

Full-scale

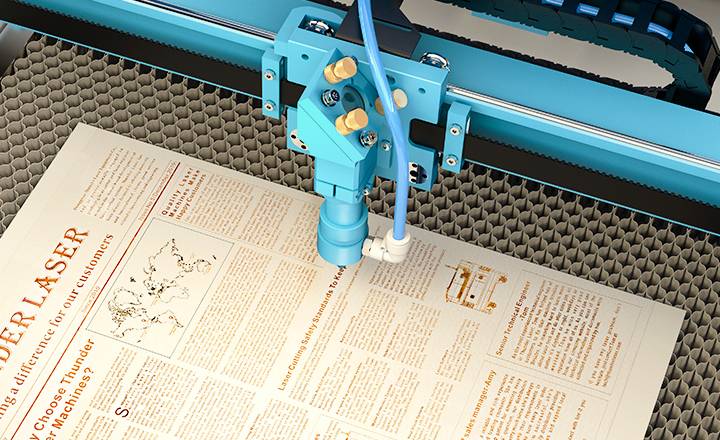

Trial Run & Final Inspection

When all components are checked and assembled, we conduct a trial run of our laser machines to test and correct their bi-directional engraving performance, cutting performance, and marking performance. The trial run also tests other aspects of our laser machines such as their energy usage, light ray output, and other factors. All tests and their results are documented and provided for you.

There is a final inspection conducted on your laser machine before we ship them out. The inspection determines the appearance and performance of the housing and accessories. Once the laser equipment passes the final inspection and meets your specifications, we seal it in premium wrapping film and packaging to protect the machinery during transport.

.png) International

International

United States

United States

Brasil

Brasil

Canada

Canada

Costa Rica

Costa Rica

Česká

Česká

Ελλάδα

Ελλάδα

Polska

Polska

Ireland

Ireland

Portugal

Portugal

Lietuva

Lietuva

Россия

Россия Deutschland

Deutschland

Britain

Britain

Україна

Україна

France

France

Sverige

Sverige

Italia

Italia

Norway

Norway

Denmark

Denmark

Romania

Romania

한국

한국

中国

中国

ประเทศไทย

ประเทศไทย

中国香港

中国香港

Israel

Israel

中國臺灣

中國臺灣

India

India

پاکستان

پاکستان

پශ්රී ලංකා

پශ්රී ලංකා

ジャパン

ジャパン

Australia

Australia

New Zealand

New Zealand

South Africa

South Africa