1. Laser marking principle

Laser marking is a marking method that leaves text and patterns on the surface of the workpiece. First, the laser marking machine irradiates the laser beam on the workpiece. The workpiece surface then vaporizes, melts, or undergoes a phase change. We call this change an instantaneous physical or chemical change.

The formation principles of laser marking patterns include following three categories:

1) To form a mark pattern by moving substances

(1) Principle:

Irradiate the workpiece with a laser with relatively high peak power. We can heat the material. Materials can melt or evaporate at high temperatures. so as to cut off some substances on the workpiece. The product has a sense of trace and carving effect.

(2) Sample product:

deep carving of metal parts such as gears and connecting rods.

2) Change the color of the material surface

(1) Principle:

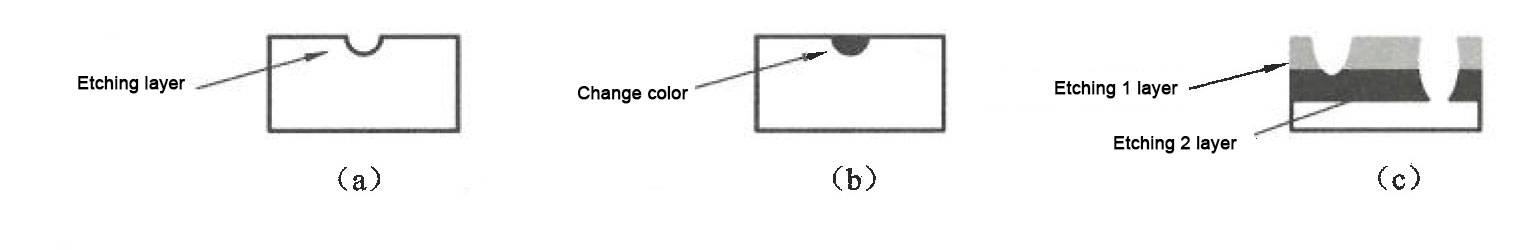

Irradiate the workpiece with a laser with relatively low peak power, and heat the material to the temperature of phase change (metal material) or denaturation (non-metal material) to change the surface color of the workpiece material, as shown in Fig. 1-25 (b).

(2) Color marking of metal materials such as stainless steel and blackening of non-metallic materials such as plastic.

3) Moving the material layers

(1) Principle:

Move one or more layers of materials in the multi-layer materials to display the color of the underlying materials and form color contrast, as shown in the figure.

(2) Sample product Laser marking of multi-layer trademark label.

2. Main methods of laser marking

Laser marking include three categories according to the way of forming marking patterns: mask marking, array marking and scanning marking.

1) Mask marking (projection marking)

(1) Typical structure of mask marker:

The outline structure diagram of the optical path system of the laser marking machine. The internal components of the optical path system include laser, mask, imaging lens and other major components.

(2) Working principle of mask marking machine: marking content on the mask

On the board, the pulsed laser emitted by the laser is uniformly projected on the mask after beam expansion. Part of the laser is transmitted from the hollow part of the mask. The graphics on the mask are imaged on the surface of the workpiece after being focused by the lens. The surface of the workpiece material irradiated by the laser forms a legible mark. Generally, each pulsed laser forms a mark.

We change the mask to achieve the conversion of the laser marking content.

Pulse CO2 laser and pulse solid YAG laser can mask marking.

2) Array marking

(1) Typical structure of array marking machine

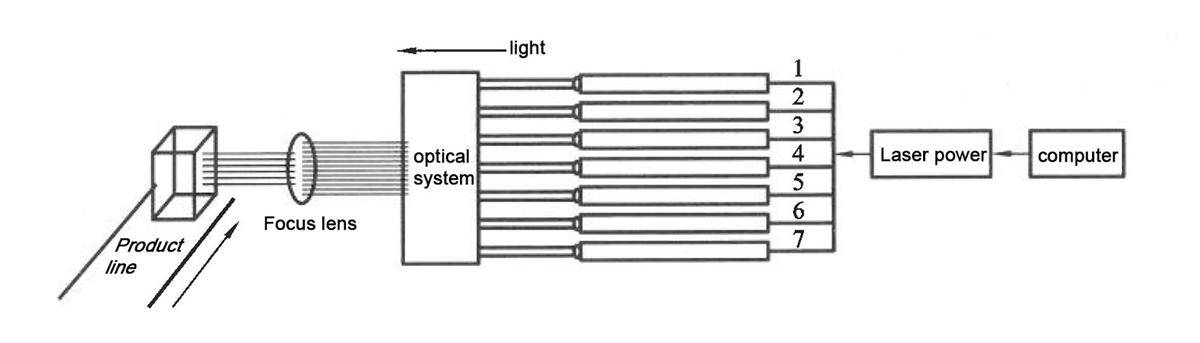

- The optical path system of array marking machine include:

- industrial personal computer,

- laser power supply,

- seven array RF CO2 lasers,

- optical coupling system and focusing mirror,

- The laser beam is on the online moving workpiece.

(2) Working principle of array marking machine:

No.1~No.7 RF CO2 lasers are vertically.

At time t1, if the industrial computer controls the laser power supply to be turned on at the same time, No.1~No.7 laser arrays will emit 7 pulse lasers at the same time, ablating 7 pits on the surface of the workpiece, forming 7 vertical strokes, which are similar to “1”.

At time t2, if the industrial personal computer controls the laser power supply to only enable laser 7, then there is only one point at the bottom.

Similarly, at t3, t4, and ts, only laser 7 is enabled. It can be seen that a 7X5 array of letters is formed in the time range from t1 to ts, as shown in the figure.

Common characters form 5 horizontal strokes and 7 vertical strokes × 7 array. When the precision is not too high × 5 array is also available.

The array marking speed can reach up to 6000 characters/s, which makes it an ideal choice for high-speed online marking. Its disadvantage is that it can only mark dot matrix characters. And it can only reach 5 × The resolution of 7 is not enough for Chinese character marking.

3) Scanning marking

(1) Working principle of scanning marking machine:

The scanning marking machine inputs the pattern into the industrial personal computer. It controls the laser to open and the scanning mechanism. It will make the laser scan on the surface of the processed material to form a marking pattern.

(2) Typical structure of scanning marking machine:

the scanning mechanism has two structural forms: mechanical scanning and galvanometer scanning.

① Mechanical scanning:

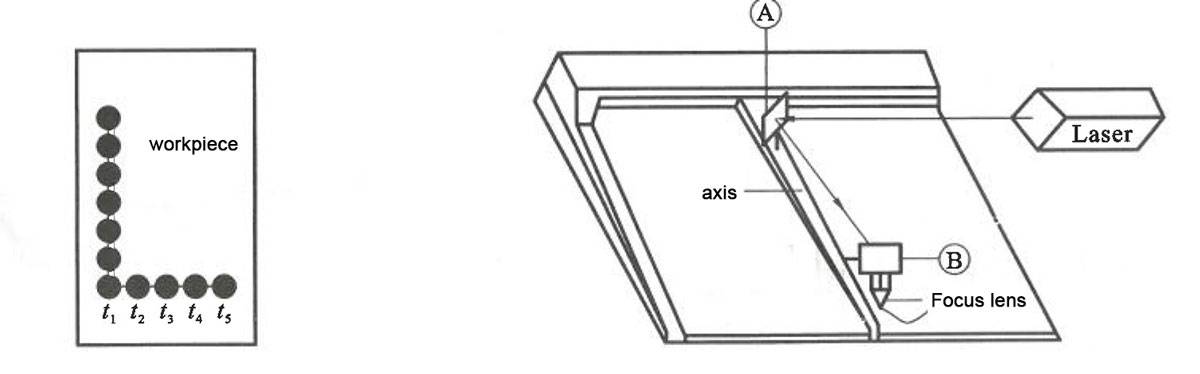

The optical system of mechanical scanning marking machine includes laser, reflector, reflector B and focusing lens.

Mechanical scanning translates the X-Y coordinate of the reflector through mechanical movement, so as to change the position where the laser beam reaches the workpiece. After turning the optical path through the reflector A and B, the laser beam acts on the workpiece through the focusing lens. The pen arm with the reflector ④ moves back and forth along the X axis; The focusing lens moves along the Y axis with the reflector (both fixed together).

Under the control of the control signal output from the parallel port of the industrial personal computer, the combination of the motion in the Y direction and the motion in the X direction makes the output laser reach any point in the plane and mark any graphics and characters.

② Galvanometer scanning: The optical system of galvanometer scanning marking machine include laser, X, Y galvanometer and flat field focusing lens

The laser beam emitted by the laser is incident on the X and Y galvanometers. The X and Y galvanometers can scan along the X and Y axes respectively.

The industrial personal computer can control the reflection angle of the mirror, so as to control the deflection of the laser beam.

After being focused by the flat field focusing lens, the laser focus with a certain power density moves on the marking material as required, leaving a marking pattern on the material surface.

Galvanometer scanning improves the quality and speed of laser marking, but the marking area is not as large as mechanical scanning marking.

.png) International

International

United States

United States

Brasil

Brasil

Canada

Canada

Costa Rica

Costa Rica

Česká

Česká

Ελλάδα

Ελλάδα

Polska

Polska

Ireland

Ireland

Portugal

Portugal

Lietuva

Lietuva

Россия

Россия Deutschland

Deutschland

Britain

Britain

Україна

Україна

France

France

Sverige

Sverige

Italia

Italia

Norway

Norway

Denmark

Denmark

Romania

Romania

한국

한국

中国

中国

ประเทศไทย

ประเทศไทย

中国香港

中国香港

Israel

Israel

中國臺灣

中國臺灣

India

India

پاکستان

پاکستان

پශ්රී ලංකා

پශ්රී ලංකා

ジャパン

ジャパン

Australia

Australia

New Zealand

New Zealand

South Africa

South Africa