How to Use a Rotary Device?

Operation Steps

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Installation

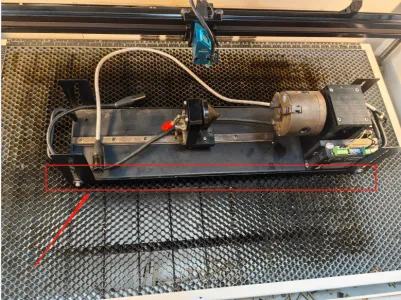

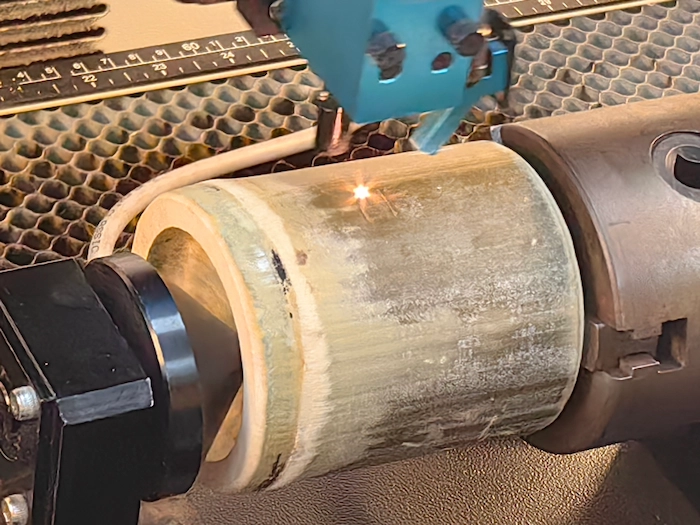

●Lower the honeycomb platform to a certain distance to allow placing the machine’s rotary fixture equipment.

●Place the rotary fixture on the honeycomb platform, ensuring it is level with the guide rails. The honeycomb holes on the platform provide a good reference, as they are on the same horizontal plane. Use them as a reference to place the rotary axis horizontally. The placement angle is closely related to the final engraving angle of the product.

●Use a horizontal line intersecting the honeycomb holes as a reference to place the rotary axis.

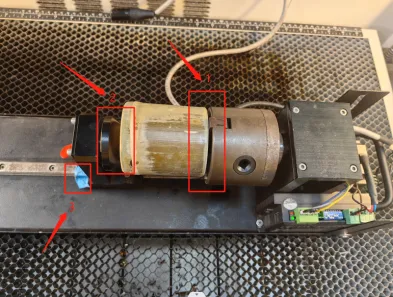

●Connect the machine’s power cable to the laser’s socket to connect the rotary fixture to the laser.

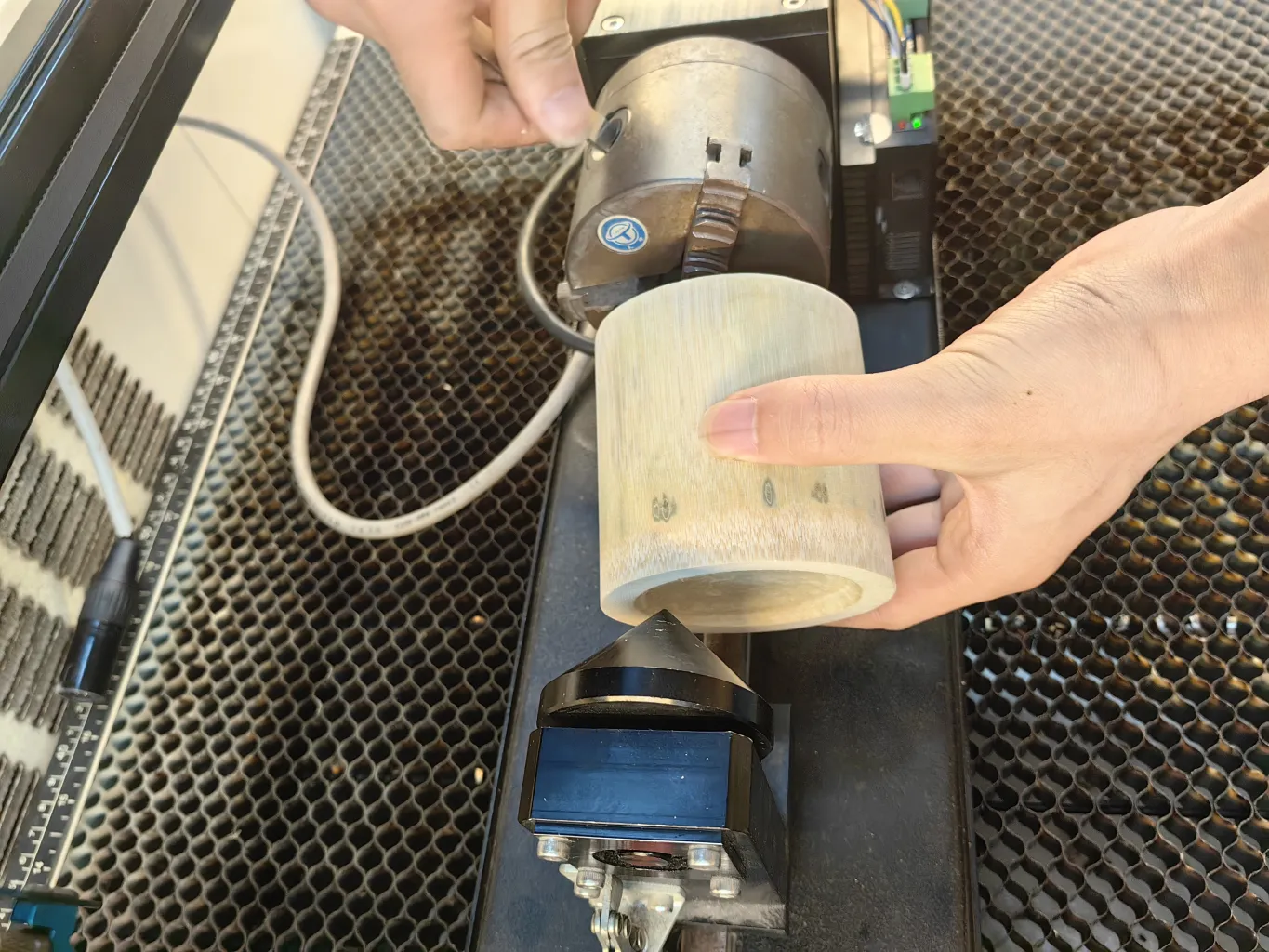

●Secure the object to be engraved on the two sides of the rotary fixture by adjusting the tightness of the fixture’s clamps. For smooth objects, you can attach sandpaper to increase friction. At this point the clamps are still a bit loose, so use a magnet at the back to secure the entire fixture and prevent the clamps from loosening – this is crucial.

File

●Click the rotary setting, select chuck type, open start rotation. The object diameter data needs to be measured before installation. The first data to fill in is fixed (this is related to the bearing gear).

●Send the file to the laser.

Machine

●On the laser control panel, click menu, select Z-axis rotation, use the left and right arrow keys to control the rotation direction of the rotary fixture.

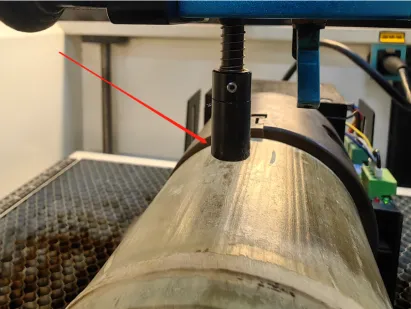

●The auto-focus probe needs to move to the center point of the test object for focusing.

●Press the file key to select the file to be engraved, confirm it is the desired file.

●Click position, then run border to check if the engraving file range is fully on the object. If confirmed, click the start switch to begin laser engraving.

.png) International

International

United States

United States

Brasil

Brasil

Canada

Canada

Costa Rica

Costa Rica

Česká

Česká

Ελλάδα

Ελλάδα

Polska

Polska

Ireland

Ireland

Portugal

Portugal

Lietuva

Lietuva

Россия

Россия Deutschland

Deutschland

Britain

Britain

Україна

Україна

France

France

Sverige

Sverige

Italia

Italia

Norway

Norway

Denmark

Denmark

Romania

Romania

한국

한국

中国

中国

ประเทศไทย

ประเทศไทย

中国香港

中国香港

Israel

Israel

中國臺灣

中國臺灣

India

India

پاکستان

پاکستان

پශ්රී ලංකා

پශ්රී ලංකා

ジャパン

ジャパン

Australia

Australia

New Zealand

New Zealand

South Africa

South Africa