Laser engraving is becoming increasingly popular, with stone being one of the many materials that can be engraved. A laser engraver for stone is a great investment for businesses, as it allows you to create custom gifts, decorations, and even engrave photos or text.

In this article, we’ll explore the benefits of laser stone engraving, types of stones suitable for engraving, and the best laser engraver options for stone.

1. Why Do You Need a Laser Engraver for Stone?

Laser engraving on rocks can replace traditional engraving methods. These traditional engraving methods might include polishing, hammering, and sandblasting. However, it would be best to choose a laser machine for engraving. Why? Because this stone laser engraving machine offers a wide range of benefits.

Precision Engraving and High Quality Finish: Laser engraver for stone provides the highest precision. Since this is a non-contact process, the finishing of the engraved stones comes with the highest quality. High-speed laser engraving requires less labor resulting in optimal production cost.

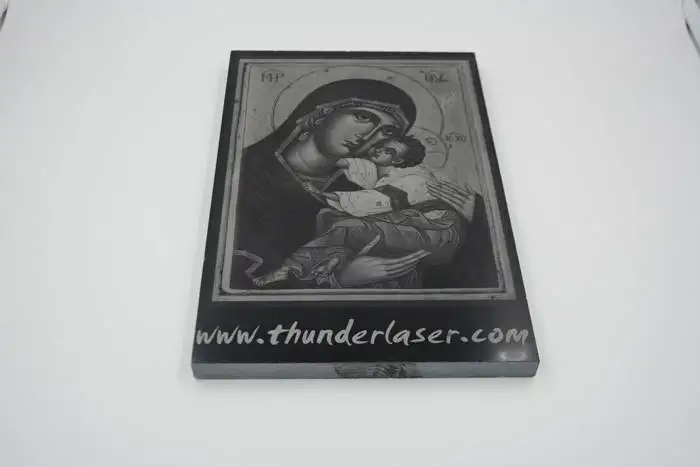

Versatility in Stone Engraving: As laser beams create precision engraving, thus you can engrave every art or calligraphy. The laser engraving software converts these designs, decorations, or effects into machine code. You can also engrave all rocks, stones, or concretes based on your required application.

Enhance Safety with Class-1 Enclosure: As mentioned, laser engraving is a non-contact process. In addition, it comes with a class-1 protective enclosure. It ensures the job is safe and keeps the area clean and tidy.

Environmental Friendly Laser Technology: Laser is an example of green technology. It doesn’t impact ecological factors such as air, water, or land. Since the laser engraving process doesn’t create pollutants, it is environmentally friendly.

Boost Product Value with Laser Stone Engraving: Laser engraver for stone adds product value. We know engraved rocks are famous for decorations, construction, and fundraising applications.

2. Best Engraver for Stone: Bolt Laser Rock Engraving Machine

When selecting a laser engraver for stone, precision and reliability are crucial. The Thunder Laser Bolt series is the best choice. The engravers are designed for versatility, handling not only stone but also a variety of materials such as wood, acrylic, glass, and more.

The Bolt series delivers precise engraving with speeds from 1000mm/s to 2000mm/s and a resolution of up to 1000 DPI, making it perfect for creating detailed designs on stone. The advanced motion control system ensures consistent, high-quality results, while the fully automated operation and class-1 laser safety enclosure provide a safe working environment.

Whether you’re engraving personalized gifts, decorative stone items, or custom signage, the Thunder Laser Bolt series offers the ideal balance of power, performance, and affordability for your stone engraving projects.

3. How to Choose the Best Laser Engraver for Stone?

While choosing a laser stone engraving machine, you should know some typical parameters of the device. There are two types of parameters: process parameters and machine parameters. Process parameters include power and pulse frequency, stone laser engraving speed and time, and laser source. On the other hand, machine parameters include additional services, after-sale services, and budget.

These parameters determine the quality of a laser rock engraving machine. In addition, they will also lead you to the right decision. Therefore, it would be best to know these parameters before buying a laser engraver for stone.

4. How to Laser Engraving Stone?

It is a typical laser engraving process, but the material is different. However, we have classified the laser engraving stone into four easy steps.

4.1. Preparing the Stone

Prepare the type of stone you want to engrave. Before placing it, ensure the stone is clean and free from dirt. If it is necessary, try to clean it first. After that, place it on top of the working table. Try to put it at the center of the functional area.

4.2. Choosing the Right Design for Laser Engraving

Choose a design, calligraphy, or text you want to engrave on the stone. You can customize the design and direction using stone laser engraving software. After that, set the laser power and speed of the nozzle. Usually, we recommend the average value of these parameters to our beloved customers. Therefore, you can get a general idea of what range of power and speed you should set for what type of materials. The following table highlights the average value, especially for stone.

| Stone Type | Power | Speed | Resolution | Z-index |

| Marble | 50% | 20% | 1000dpi | -0.5mm |

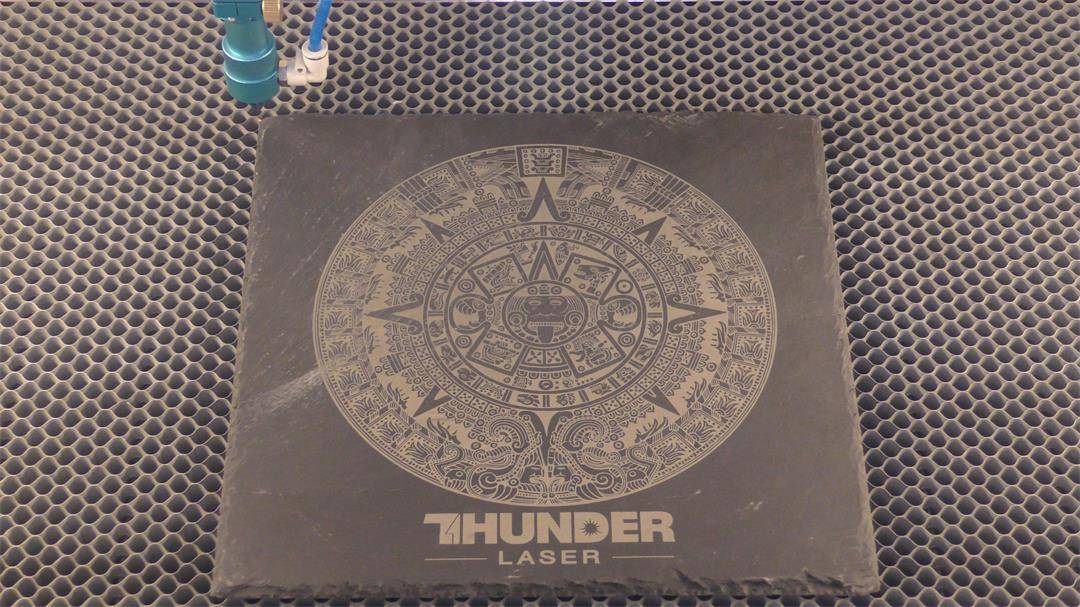

| Slate | 20% | 100% | 500dpi | 0 |

| Concrete | 100% | 20% | 500dpi | 0 |

| Pebbles | 80% | 30% | 500dpi | +2 |

| Basalt | 12% | 50% | 500dpi | -1 |

| Agate | 50% | 30% | 1000dpi | +1.5 |

| Bricks | 100% | 30% | 500dpi | +1.5 |

4.3. Setting Up the Laser Engraver

After you set the power and speed of the laser engraver for stone, now you should check the focus point of the laser gun. Place the red rectangular light on top of the rock where you want to engrave the design. Now, close the enclosure and start the process.

4.4. Post-Engraving Finishing

After engraving the stone, the dust and contaminants will remain. Therefore, you may need an additional step for polishing and giving it a good look.

5. What Types of Stones Are Suitable for Laser Engraving?

All types of rocks are suitable for laser engraving. But quality may not be similar for all of them. Quality finishing requires a polished and flat surface so that the stone’s surface can not distort the final result. Therefore, a smooth, clean, flat surface provides the best results. However, if you want to engrave a round surface, you can install a rotary attachment or modelling clay. The following types are the most common stones that are widely popular in stone engraving businesses.

5.1. Granite

This stone is the most common and comparatively cheap than other rocks. It consists of 10% to 60% of quartz and feldspar. The higher the quantity of quartz, the more robust and durable stone. Typically, higher quartz granite is ideal for outdoor applications. However, other factors may also alter the quality of the engraving, such as color, grains, fossils/veins, and composition.

5.2. Slate

This stone is traditionally popular as a construction material. It is one type of natural rock famous for its strength and excellent resilience. These properties make this rock one of the most durable stones for roofing. However, laser engraving increases the beauty of a slate. As a result, you may find these engraved stones in gift and decorations shops.

5.3. Marble

This stone is a metamorphic rock that comes in various colors. Besides, it has a smooth polished finish surface. Therefore, laser engraving on marble stone is highly noticeable. As a result, people love this type of engraved stone as a gift or decoration.

5.4. Ceramics

Bricks and tiles are the most common ceramic materials for laser engraving stone. However, these two ceramics are famous for fundraising, memorials, or decorations.

5.5. Pebbles and Agate

These two types of stones are more beautiful than other stones. However, pebbles are small rounded stones primarily found in rivers and fountains. On the other hand, agate is a typical rock formation that comes with a wide variety of colors.

Conclusion

Laser engraved stone is a popular choice for luxury homes, memorials, and fundraising items due to its durability. Marbles, pebbles, and agates with laser-engraved designs also make great gifts. Starting a laser engraving stone business can be profitable, especially with the right machine. Thunder Laser is a leading manufacturer of high-quality, reliable laser engravers. If you have any questions, feel free to contact us via email, phone, or WhatsApp.

FAQs About Best Laser Engraver for Stone

Q1. Can all types of stones be laser engraved?

Yes, all types of stones, such as granite, slate, marble, and agate, can be laser engraved, though surface quality and texture may affect the final result.

Q2. How long does it take to laser engrave a stone?

The time it takes to engrave a stone depends on the design’s complexity, the stone’s size, and the engraver’s settings. Generally, simpler designs take less time, while more intricate ones require longer engraving sessions.

Q3. Can I laser engrave on rough or uneven stones?

Laser engraving works best on smooth, flat surfaces. However, rough or uneven stones can still be engraved with proper preparation, such as using a rotary attachment or special clamps.

Q4. Should I need to clean the stone after laser engraving?

Yes, after laser engraving, dust and residue may remain on the stone. Cleaning or polishing the engraved area ensures a high-quality finish and enhances the visibility of the design.

Q5. Can I use a laser engraver for stone outdoors?

While laser engravers can be used for outdoor applications, they should be operated in a clean, dry environment to ensure proper functionality and longevity. It’s also important to have appropriate ventilation if working outdoors.

.png) International

International

United States

United States

Brasil

Brasil

Canada

Canada

Costa Rica

Costa Rica

Česká

Česká

Ελλάδα

Ελλάδα

Polska

Polska

Ireland

Ireland

Portugal

Portugal

Lietuva

Lietuva

Россия

Россия Deutschland

Deutschland

Britain

Britain

Україна

Україна

France

France

Sverige

Sverige

Italia

Italia

Norway

Norway

Denmark

Denmark

Romania

Romania

한국

한국

中国

中国

ประเทศไทย

ประเทศไทย

中国香港

中国香港

Israel

Israel

中國臺灣

中國臺灣

India

India

پاکستان

پاکستان

پශ්රී ලංකා

پශ්රී ලංකා

ジャパン

ジャパン

Australia

Australia

New Zealand

New Zealand

South Africa

South Africa