Introduction

You can mark plastic with laser-precision accuracy with a laser marking machine for plastic. These machines make a great alternative to traditional mechanical and chemical etching. Laser marking machines for plastic offer superior accuracy and laser-sharp precision. Laser marking plastic is the ideal solution for any business who wants to get their message with high quality results.

Businesses can also reap maximum benefits from laser marking plastic. With laser technology, businesses get superior accuracy and laser-precision perfection. Laser marking machine on plastic helps to make permanent marks on plastics with ease. These machines are also ideal for both short production runs as well as large-scale industrial applications.

Plus, plastic laser marking is also more cost-effective than traditional methods, saving time and money in the long run. Discover why laser marking plastic is the way to go. Get ready to enjoy precision like never before with laser plastic marking machines.

What is laser marking plastics?

Laser marking plastics is a cutting-edge technology that enables manufacturers to customize their products with durable and permanent marks. It uses laser beams of different frequencies and intensities, along with specialized software to create distinctive markings on many types of plastics. The laser marking machine for plastic is an efficient tool for creating detailed markings and logos on any kind of plastic surface.

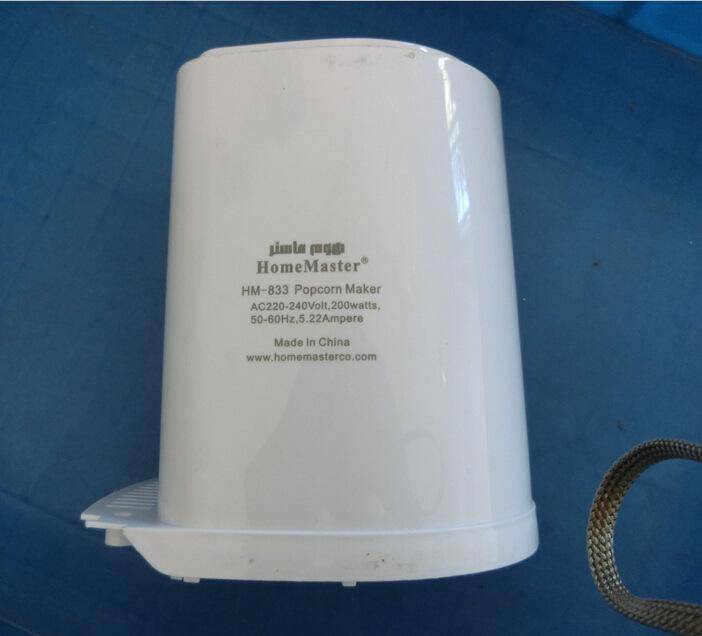

This type of technology also eliminates traditional methods such as stamping or branding that can cause damage to the product. The laser marking machine for plastics also eliminates much of the labor involved in traditional processes. Plastic laser marking is ideal for applications such as auto part identification, medical device labels, appliance identification tags, and much more.

With this advanced process, companies can now customize their products with detailed marks without sacrificing accuracy. By taking advantage of this modern technology, businesses are producing high-quality marks quickly and efficiently.

The Value of Employing a Laser Marking Machine For Plastic

What’s more, an essential part of any production line is the laser marking machine.

Here are some of the benefits that make laser marking machines ideal for plastic materials:

1. Precision & Quality.

Laser marking machines offer precision when applied to plastic materials. It enables users to create clean and high quality marks with consistent accuracy. These machines also make it easy to apply brand logos or symbols onto plastics quickly and effectively.

2. Durability.

Laser marked designs will not easily fade or wear off, even when exposed to heat, chemicals and other harsh elements. This makes it an ideal choice for businesses that need their markings to remain visible over a longer period of time.

3. Cost-Efficiency.

Compared to traditional marketing methods, laser marking machines are more cost-efficient. These machines require minimal maintenance and can produce high volumes of markings in less time. In addition, laser marking devices eliminate the need for ink and other supplies, reducing operating costs.

4. Provides precision, quality and durability to cost efficiency.

The use of laser marking machines for plastics brings about numerous benefits for businesses involved in plastic production or manufacturing. Laser marking machines are also going to completely change the plastics sector with their speed and precision marking capabilities.

5. Perfect solution for businesses.

When it comes to marking plastics, laser marking machines also offer the perfect solution. Moreover, laser marking plastic is an incredibly efficient way to create lasting marks. With laser marking, you can add permanent identifications onto plastics. Laser marking plastic provides a precise mark every time.

6. Offers superior precision and control.

The laser marking machines are also incredibly powerful tools for plastics manufacturers. These tools also allow manufacturers to quickly and accurately mark large batches of parts with minimal effort. For companies that need to mark plastic parts with speed and accuracy, laser marking machines are the perfect choice. Moreover, these machines offer superior precision and control while eliminating the possibility of errors caused by manual approaches.

7. Produce a wide range of intricate designs.

Laser marking plastics also enable businesses to produce a wide range of intricate designs in a fraction of the time required for conventional marking methods. With this technology, manufacturers can save both time and money on their projects while still creating beautiful and professional results every time.

How does a plastic laser marking machine work?

- Laser marking machines use light to permanently mark plastic surfaces with text, images, or logos.

- It works by focusing a high-powered laser beam on the surface of the plastic material being marked.

- The laser beam vaporizes small portions of the surface, creating a permanent marking in the form of text, image or logo onto the material.

- In order to produce the laser light, either solid state lasers like Nd-Yag or fiber lasers, or gas lasers like CO2 and excimer laser systems are used. Each type has its own advantages depending on specific needs and applications.

- The laser beam is then directed through a series of lenses and mirrors, which focus the beam on the exact point where the marking needs to take place. This process is repeated until all of the required markings are applied onto the plastic surface.

The result is a high-quality mark is permanent, accurate, and cost-effective compared to other marking processes. Laser marking machines can also help reduce waste in production. Moreover, by using lasers for plastic marking, manufacturers can make sure that their products have a professional and distinctive look to them.

Different Types of Plastic laser marking machines.

CO2 laser marking plastic.

CO2 laser marking is a modern process for marking plastics, making it possible to add intricate designs onto plastic surfaces. With this method, laser beams are directed onto the surface of the plastic material, which causes the plastic to be permanently marked with a design. The result is an attractive and durable permanent marking that cannot be removed or altered.

CO2 laser marking on plastic also offers a range of advantages over traditional printing methods. In addition, the long lasting nature of the markings, along with the accuracy and quick setup times makes it ideal for many types of product packaging, labeling and industrial applications.

Uses of CO2 Laser Marking on Plastic:

- Packaging & Labeling Applications.

The permanent and long lasting nature of laser markings make them ideal for use in product packaging applications. Companies can also use laser markings to create unique labels with detailed branding information that will last over the life of the product.

- Industrial Manufacturing Processes.

CO2 laser marking is often used in industrial manufacturing processes for marking parts, components and other items. Moreover, it also helps to ensure quality control and traceability of products throughout the production process.

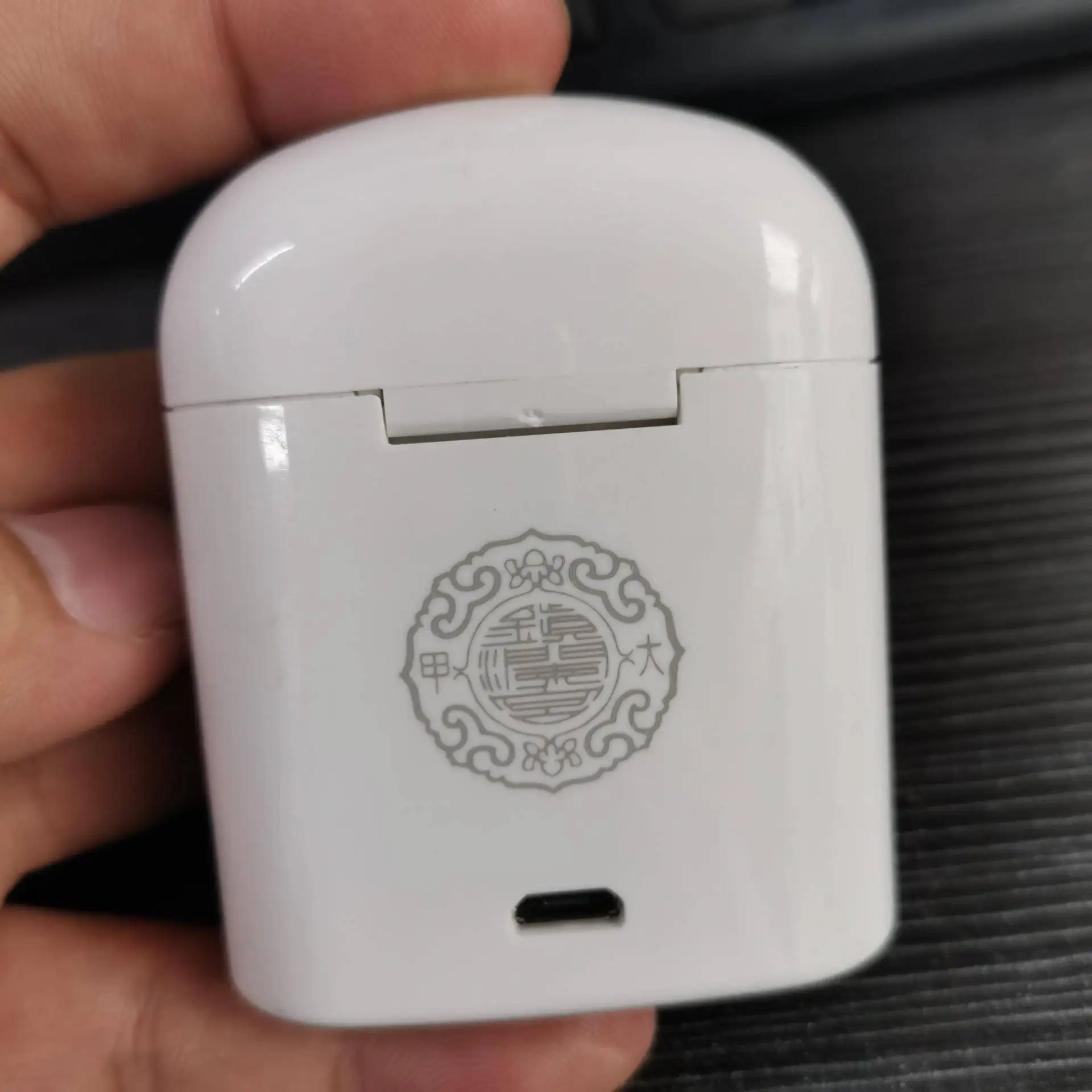

- Promotional Gifts & Merchandise.

CO2 laser marking plastics produce high-quality promotional gifts and merchandise such as keychains, USB drives, pens or mugs. Companies can laser mark their logos, taglines or other branding information onto these items to make them more memorable.

Color laser marking on plastic.

Color laser marking on plastic is an effective and efficient way of adding color to products, allowing for permanent color identification. Using a color laser marking machine, logos, graphics, text and barcodes businesses can apply with precision onto any plastic substrate. This process provides several advantages over traditional methods such as long-lasting color retention, higher resolution and a greater color range.

In addition, compared to conventional procedures, color laser marking on plastic is both quicker and cheaper. Thus, color laser marking is gaining popularity in several industries. These applications include nameplates, identification tags, warning labels and promotional products.

This process also helps to customize products quickly and effectively, adding color and information to products without affecting their underlying substrate. Moreover, color laser marking on plastic is also a great way to add color for decorative purposes and brand promotion.

Uses of Color Laser Marking On Plastic:

- Automotive Parts.

Differentiate your product from competitors by adding customized logos or text to automotive parts using a color laser marking machine.

- Medical Devices.

Increase the safety of medical devices by clearly labeling each component with color laser markings.

- Industrial Electronics.

Businesses can quickly label industrial electronics with permanent and vibrant color laser markings.

- Consumer Goods.

This machine enhances the look of consumer goods with intricate logos or text using color laser marking machines.

- Text Marking.

Text markings provide product identification by adding information like part numbers, serial numbers and expiration dates.

- Security Markings.

Laser marking helps businesses to add security by adding hidden markings or codes onto the plastic surface.

- Graphics and Artwork.

Color laser marking technology can add visuals onto the product for aesthetic purposes or for instruction manuals and advertising materials.

Fiber laser marking machine for plastic

Fiber laser marking machines are the most powerful laser markers on the market today. These marking machines require a power output of 20 to 50 watts. Engraving and three-dimensional etching are ideal applications for fiber laser marking machines.

Common applications include working with hard metals and situations calling for great power and resolution. In addition, these machines are useful for marking thin materials. The tiny marking components are in large batches because of their small spot sizes and good beam clarity.

Uses of Fiber Laser Marking Machines for Plastic:

- Marking on Curved Surfaces.

Businesses can use fiber lasers on curved surfaces like bottles, containers and other round objects with ease.

- Quality Assurance.

Laser marking machines allow manufacturers to monitor the quality of their plastic products by adding identifying marks. Moreover, scanners can easily read these marks for quick verification purposes.

- Durability.

One of the most attractive features of fiber laser marking machines is that the markings they create are extremely durable and will not wear away or fade over time.

- Cost Effectiveness.

This technology is a cost-effective way to mark products with information without having to perform multiple rounds of printing processes.

- Efficiency.

Fiber laser marking machines allow manufacturers to quickly mark their plastic products in a single pass with minimal downtime.

- User-Friendly Software.

Most fiber laser systems come with an intuitive user interface which makes them easy to use even for first-time operators.

Conclusion

In conclusion we can say that laser marking machines for plastic have revolutionized the process of plastic engraving and marking. From small scale hobbyists to large industrial operations, laser marking machines offer precision, accuracy and reliability that would be hard to match by any other method. With its superior quality and durability, laser marking on plastics is the ideal choice for any application.

Moreover, businesses can use these machines for permanent marks or logos in a cost-efficient manner. Whether you need to mark labels or identifiers on product components, laser marked plastics offer a long lasting professional finish. Furthermore, investing in one of these versatile machines is sure to bring excellent value for money. Laser marking machine for plastic is your answer for reliable and lasting results.

.png) International

International

United States

United States

Brasil

Brasil

Canada

Canada

Costa Rica

Costa Rica

Česká

Česká

Ελλάδα

Ελλάδα

Polska

Polska

Ireland

Ireland

Portugal

Portugal

Lietuva

Lietuva

Россия

Россия Deutschland

Deutschland

Britain

Britain

Україна

Україна

France

France

Sverige

Sverige

Italia

Italia

Norway

Norway

Denmark

Denmark

Romania

Romania

한국

한국

中国

中国

ประเทศไทย

ประเทศไทย

中国香港

中国香港

Israel

Israel

中國臺灣

中國臺灣

India

India

پاکستان

پاکستان

پශ්රී ලංකා

پශ්රී ලංකා

ジャパン

ジャパン

Australia

Australia

New Zealand

New Zealand

South Africa

South Africa