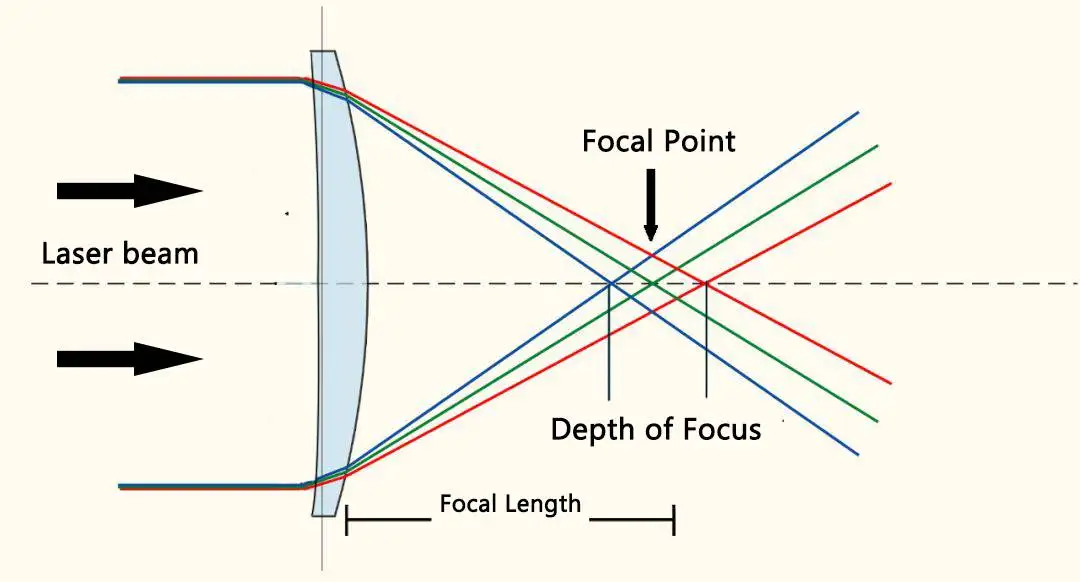

Selecting the appropriate laser head can be a key factor in achieving optimal laser effects. The commonly used laser heads for Thunder Laser equipment range from 1.5″ to 4″. The different inches represent the distance between the lens and the laser beam’s focal point.

| Type | Laser dot Size | Focal Distance | Main Function |

|---|---|---|---|

| Standard Laser Head | 0.0039″(0.099mm) | 5.0mm~6.5mm | Cutting material less than 10mm, Engraving photos within 500DPI |

| High Resolution Head | 0.0020″(0.050mm) | 3.0mm~4.0mm | Engraving photos up to 1000DPI, cutting material less than 1mm |

| 4″ Laser Head | 0.0078″(0.198mm) | 9.0mm~11mm | Cutting material more than 10 mm |

For Thunder Laser’s Nova series laser cutting machines, the standard lens is 2.0″, providing balanced performance for both engraving and cutting. It’s the most commonly used laser head.

In general, smaller focal length lenses (1.5″) are better suited for extremely fine details, whereas larger focal length lenses (2.5″, 4.0″) are mainly used for cutting thicker materials due to their deeper focal points.

When to Use Shorter Focal Length (1.5″ or HR) Lenses:

Shorter focal length lenses, like the 1.5″ lens, create a small laser spot at the focus point, enabling very fine detail engraving and high power density. A side effect is that engraving lines might appear more pronounced when working on larger areas, as the spot is small and lines don’t overlap. This can lead to a slightly rough surface and less transparent colors on the engraved material. Increasing the Z-axis offset can help reduce this effect by moving the focus point away and expanding the laser spot.

Using Longer Focal Length (2.5″) for Engraving:

When working with temperature-sensitive materials (such as plastics), a larger spot generates less heat. As a result, it reduces the potential distortion during extensive engraving on large areas.

Using the 4.0″ Lens for Cutting:

For thicknesses exceeding one inch during cutting, using the 4.0″ lens is advantageous to achieve more vertical cutting edges.

.png) International

International

United States

United States

Brasil

Brasil

Canada

Canada

Costa Rica

Costa Rica

Česká

Česká

Ελλάδα

Ελλάδα

Polska

Polska

Ireland

Ireland

Portugal

Portugal

Lietuva

Lietuva

Россия

Россия Deutschland

Deutschland

Britain

Britain

Україна

Україна

France

France

Sverige

Sverige

Italia

Italia

Norway

Norway

Denmark

Denmark

Romania

Romania

한국

한국

中国

中国

ประเทศไทย

ประเทศไทย

中国香港

中国香港

Israel

Israel

中國臺灣

中國臺灣

India

India

پاکستان

پاکستان

پශ්රී ලංකා

پශ්රී ලංකා

ジャパン

ジャパン

Australia

Australia

New Zealand

New Zealand

South Africa

South Africa