Introduction

Let’s make your brass into wonderful wax seals! Laser etching can creates deep custom designs on brass easily.

Ready to give your laser etching brass wax seals the attention they deserve? Check out the steps below and etch your way to success!

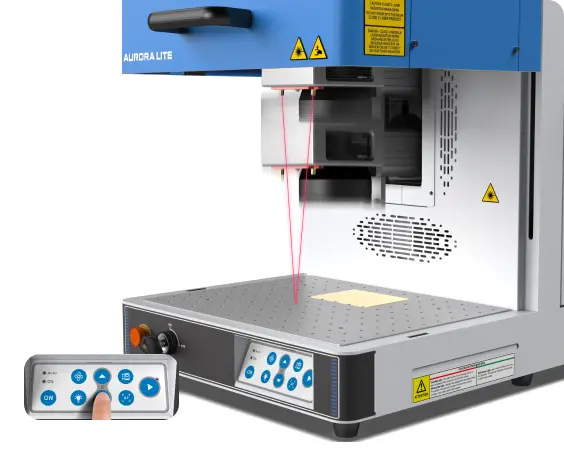

Machine Used

Aurora Lite 50W

Material Needed

Brass

Settings

- Laser Etching

- Speed: 1000mm/s

- Marking Power: 90%

- Frequency: 50kHz

- Line interval: 0.02

- Laser Cleaning

- Speed: 1000mm/s

- Marking Power: 20%

- Frequency: 70kHz

- Line interval: 0.02

Check out!

- The machine is connected and operating normally, and the lens cover has been removed.

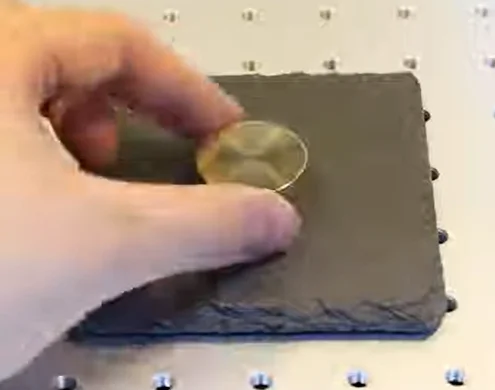

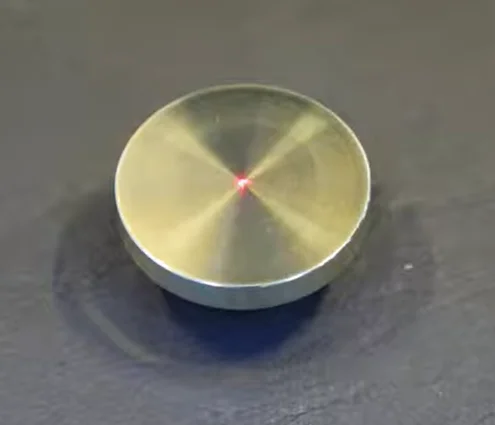

Step 1: Place the brass wax seals for laser etching

Put down the brass wax seals.

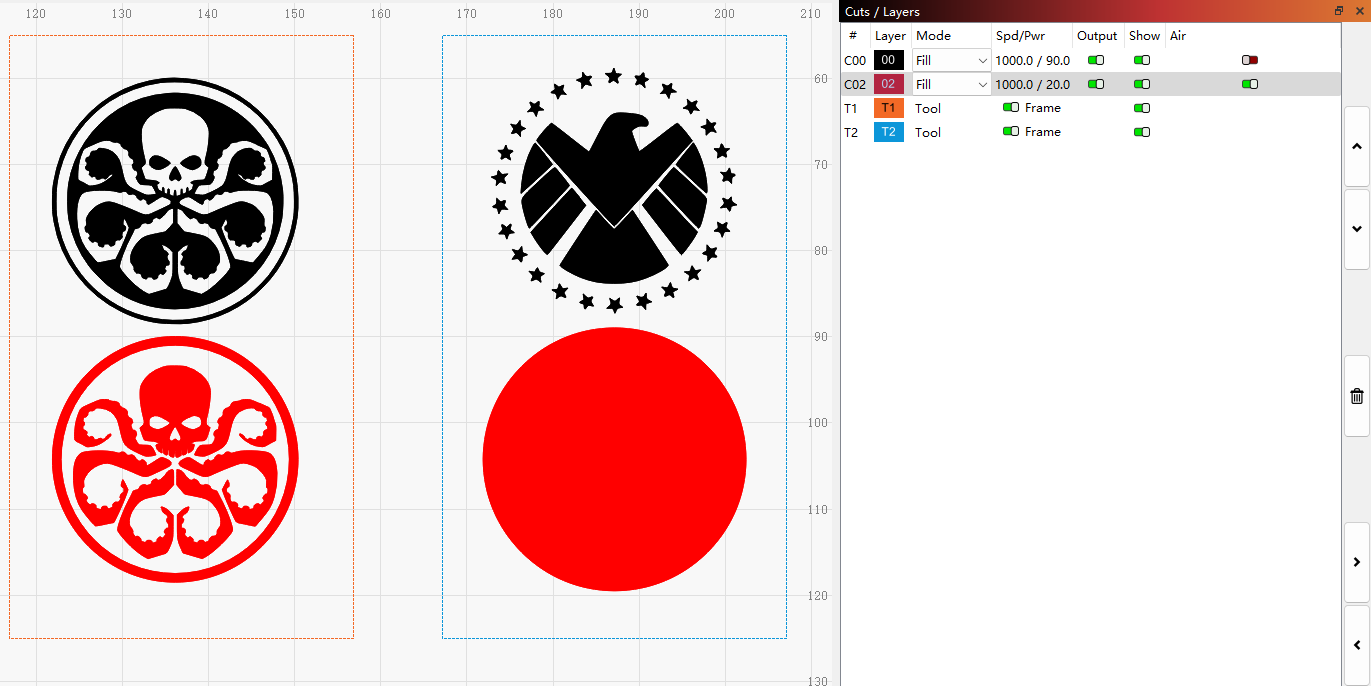

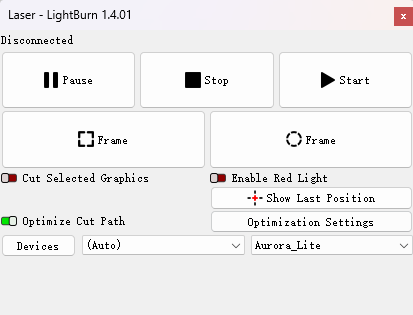

Step 2: Import laser etching file and check out

Load your design into LightBurn software, adjusting its size and position to fit you brass wax seals. Then make sure the laser etching parameters are set correctly.

We prepared two layers. The black one is responsible for leaving a deep etching on the brass, while the red layer cleans the brass surface after the laser etching.

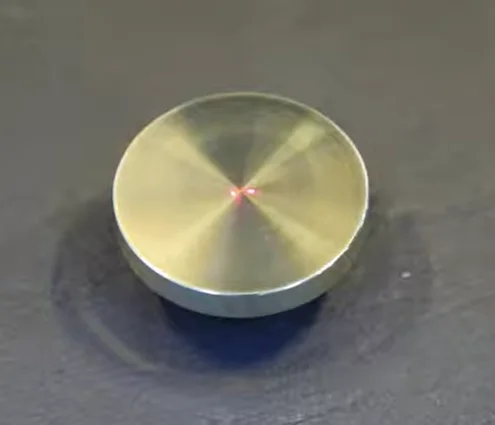

Step 3: Don't miss the focus

Missing the focus is one of the biggest reasons for laser etching failure. So don’t forget to click the AF button for auto focus. Of course, manual focus is also effective.

When two red dots are displayed on the brass, it is out of focus. When the two light dots overlap each other, it means in focus.

Auto focus

Manual focus

Out of focus

In focus

Step 4: Ready to start laser etching

Press the frame button and check if the visual red light indicate the right area to be etched. The frame should fit the brass seals. If not, move the pattern positions until they align.

After checking, close the laser door and begin Aurora Lite’s operation.

Step 5: Monitor the brass wax seals laser etching

Stay near the machine throughout operation to monitor for any unusual sounds or alarms. This vigilance ensures safety during etching, as laser energy is potent. Avoid looking directly at the laser beam, even with protective measures in place.

Laser etching brass seals

Laser cleaning brass seals

Step 6: Complete the laser etching

Once laser etching is complete, carefully open the door and get your newly personalized brass wax seals. Laser etching does not produce toxic substances, and you can use the laser etching brass wax seals after a simple cleaning!

Come and Try!

Brass wax seals add a touch of elegance and tradition to your letters, invitations, and packaging. Crafted for durability and precision, these laser etching seals create crisp, detailed impressions in wax, making every correspondence feel personal and distinguished. Whether you’re sealing wedding invitations, business documents, or handmade gifts, laser etching brass wax seals offer a timeless and stylish way to leave a lasting impression.

.png) International

International

United States

United States

Brasil

Brasil

Canada

Canada

Costa Rica

Costa Rica

Mexico

Mexico

Česká

Česká

Romania

Romania

Polska

Polska

Ireland

Ireland

Portugal

Portugal

Lietuva

Lietuva

Россия

Россия Deutschland

Deutschland

Britain

Britain

Україна

Україна

France

France

Sverige

Sverige

Italia

Italia

Norway

Norway

Denmark

Denmark

Ελλάδα

Ελλάδα

한국

한국

中国

中国

ประเทศไทย

ประเทศไทย

中国香港

中国香港

Israel

Israel

中國臺灣

中國臺灣

India

India

پاکستان

پاکستان

پශ්රී ලංකා

پශ්රී ලංකා

ジャパン

ジャパン

Australia

Australia

New Zealand

New Zealand

South Africa

South Africa