Laser engraving involves directing a concentrated laser beam onto a material’s surface to remove layers and create a predetermined design. When applied to mirrors, the laser typically targets the reflective coating on the back, vaporizing specific areas to reveal the transparent glass beneath. This process results in a design that is visible from the front, offering a striking contrast between the reflective and engraved sections.

It’s crucial to note that engraving directly on the mirror’s front surface can be hazardous, especially with diode lasers, as the reflective nature of the mirror can redirect the laser beam, potentially damaging the equipment or causing injury. Therefore, the standard practice is to engrave the mirror from the back, ensuring both safety and optimal design clarity.

Advantages of Laser-Engraved Mirrors

Precision and Detail

Laser engraving offers unparalleled precision, allowing for the reproduction of intricate designs and fine details that might be challenging with traditional etching methods. This high level of accuracy makes it ideal for creating complex patterns, detailed images, and crisp text.

Durability

Engraving on the back of mirrors, known as reverse engraving, protects the design from external wear and tear, ensuring longevity. Additionally, such engravings are more resistant to fingerprints and smudges, maintaining their aesthetic appeal over time.

Versatility

Laser-engraved mirrors are versatile in application, suitable for personalized gifts, decorative home accents, corporate branding, and commemorative items. Their customizable nature allows for a wide range of creative expressions tailored to individual preferences.

Selecting the Appropriate Mirror for Engraving

The choice of mirror significantly influences the engraving outcome. Consider the following factors:

Thickness

Thinner mirrors are generally preferred for engraving as they require less laser power and reduce the risk of heat damage. Thicker mirrors may necessitate multiple passes, increasing processing time and potential thermal stress.

Coating Type

Mirrors come with various backing materials, such as paint, plastic, or specialized coatings. Understanding the composition of this reflective layer is crucial, as it affects how the laser interacts with the mirror and the quality of the engraving.

Base Material

The mirror’s base, typically glass, should be free from imperfections like bubbles or scratches, which can compromise the engraving quality. A smooth, flawless surface ensures a clean and precise design.

Preparing for Laser Engraving

Safety Precautions

Prioritizing safety is essential when laser engraving mirrors:

Ventilation

Engraving can produce smoke and potentially toxic fumes, especially from certain coatings. Ensure adequate ventilation or use an exhaust system to maintain air quality.

Protective Equipment

Wear appropriate safety gear, including laser safety glasses to protect your eyes and gloves to handle materials safely. Laser Engraving Tips

Secure Positioning

Firmly secure the mirror to prevent movement during engraving, which could lead to misalignment or accidents.

Mirror Preparation

Cleaning

Thoroughly clean the mirror’s surface to remove dust, oils, or residues that could interfere with the engraving process. Use a lint-free cloth and appropriate glass cleaner.

Masking

Apply masking tape to areas not intended for engraving to protect them from accidental laser exposure. This step is particularly useful when working with complex designs requiring precise delineation.

Engraving Process

Design Preparation

Using graphic design software, create or import the desired image or text. Since the engraving occurs on the mirror’s back, remember to horizontally flip (mirror) the design to ensure correct orientation when viewed from the front.

Laser Settings

Adjust the laser engraver’s settings based on the mirror’s characteristics and desired engraving depth. Key parameters include:

Power

Higher power settings remove more material but increase the risk of damaging the mirror. Start with a moderate setting and adjust as needed.

Speed

Faster speeds result in shallower engravings, while slower speeds allow for deeper cuts.

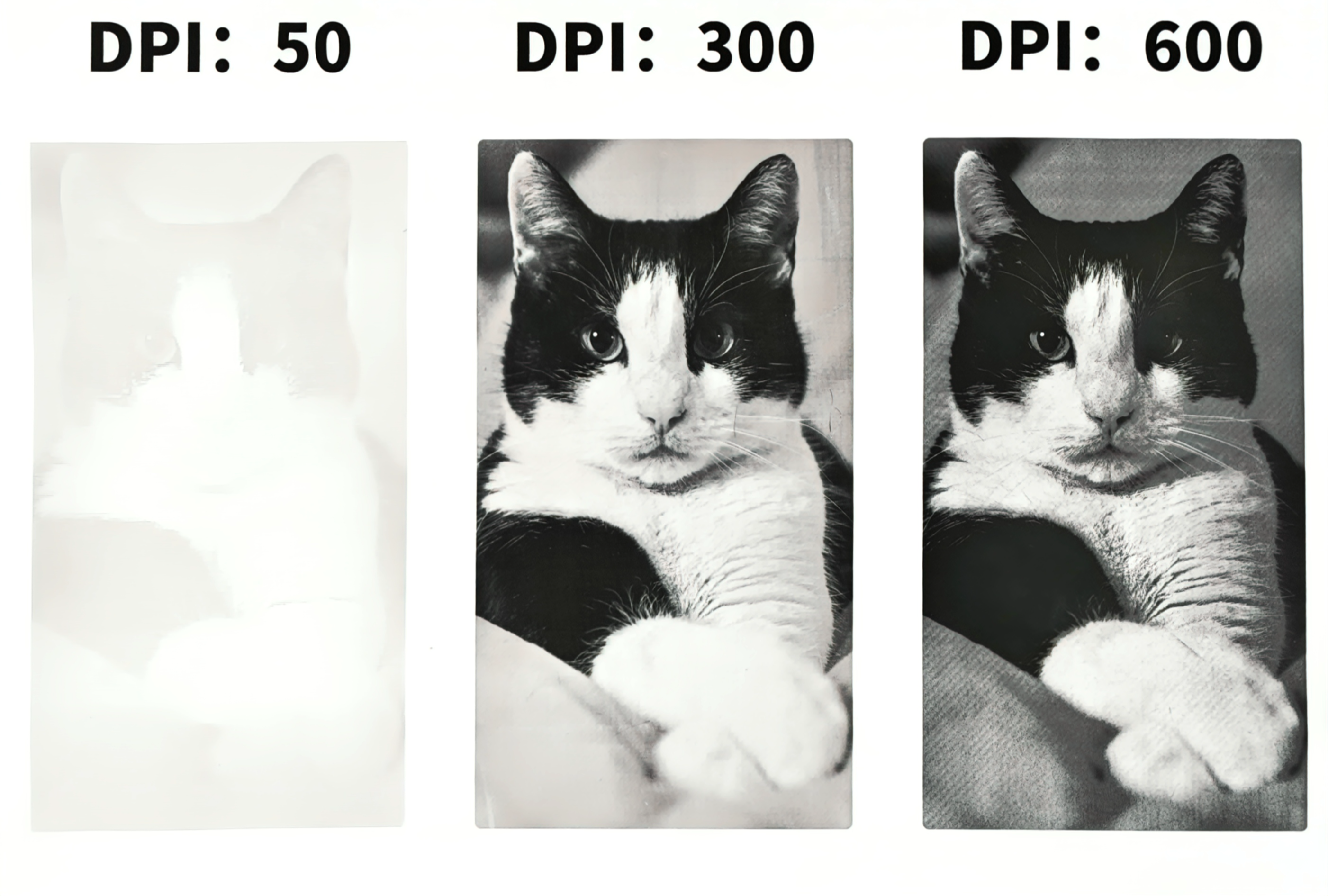

Resolution (DPI)

Higher dots per inch yield finer details but may require longer processing times.

Conducting test engravings on a sample piece can help determine optimal settings.

Focusing

Properly focus the laser to ensure precision. Some machines offer autofocus features to simplify this step.

Engraving

Once settings are configured, initiate the engraving process. Monitor the operation to ensure consistent quality and address any issues promptly.

Post-Engraving Finishing

After engraving:

Cleaning

Remove any residual debris from the engraved areas using a soft brush or cloth. Ensure the surface is clean before proceeding to additional finishing steps.

Painting (Optional)

To enhance the visibility and contrast of the engraved design, consider applying

.png) International

International

United States

United States

Brasil

Brasil

Canada

Canada

Costa Rica

Costa Rica

Mexico

Mexico

Česká

Česká

Romania

Romania

Polska

Polska

Ireland

Ireland

Portugal

Portugal

Lietuva

Lietuva

Россия

Россия Deutschland

Deutschland

Britain

Britain

Україна

Україна

France

France

Sverige

Sverige

Italia

Italia

Norway

Norway

Denmark

Denmark

Ελλάδα

Ελλάδα

한국

한국

中国

中国

ประเทศไทย

ประเทศไทย

中国香港

中国香港

Israel

Israel

中國臺灣

中國臺灣

India

India

پاکستان

پاکستان

پශ්රී ලංකා

پශ්රී ලංකා

ジャパン

ジャパン

Australia

Australia

New Zealand

New Zealand

South Africa

South Africa