| Type | Laser dot Size | Focal Distance | Main Function |

| Standard Laser Head | 0.0039″(0.099mm) | 5.0mm~6.5mm | Cutting material less than 10mm, Engraving photos within 500DPI |

| High Resolution Head | 0.0020″(0.050mm) | 3.0mm~4.0mm | Engraving photos up to 1000DPI, cutting material less than 1mm |

| 4″ Laser Head | 0.0078″(0.198mm) | 9.0mm~11mm | Cutting material more than 10 mm |

Choosing the right laser heads plays a crucial role in achieving precise engraving and efficient cutting results. Thunder Laser offers a variety of laser heads with different focal lengths and laser dot sizes, each tailored to specific applications—from fine photo engraving to cutting thick materials. Understanding how these laser heads work and when to use them can help you unlock the full potential of your laser system.

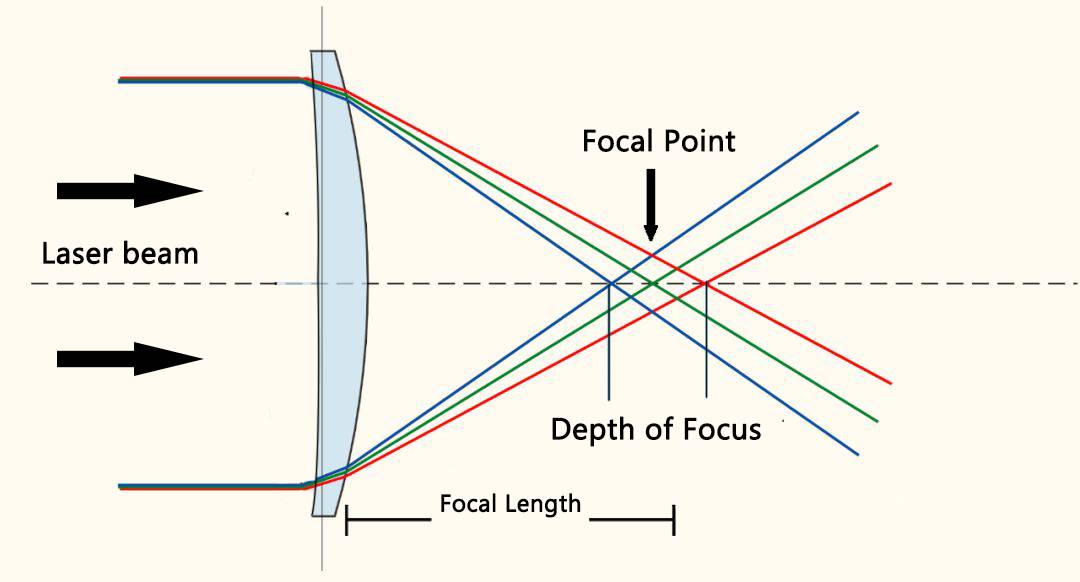

1. Understanding Laser Heads and Focal Lengths

The commonly used laser heads for Thunder Laser equipment range from 1.5″ to 4″. The different inches represent the distance between the lens and the laser beam’s focal point.

For Thunder Laser Nova series laser cutting machines, the standard lens is 2.0″, providing balanced performance for both engraving and cutting. It’s the most commonly used laser head.

In general, smaller focal length lenses (1.5″) are better suited for extremely fine details, whereas larger focal length lenses (2.5″, 4.0″) are mainly used for cutting thicker materials due to their deeper focal points.

2. When to Use Shorter Focal Length (1.5″ or HR) Lenses

Shorter focal length lenses, like the 1.5″ lens, create a small laser spot at the focus point, enabling very clear detail engraving and high power density. A side effect is that engraving lines might appear more pronounced when working on larger areas, as the spot is small and lines don’t overlap.

This can lead to a slightly rough surface and less transparent colors on the engraved material. Increasing the Z-axis offset can help reduce this effect by moving the focus point away and expanding the laser spot.

3. Using Longer Focal Length (2.5″) for Laser Engraving

The 2.5-inch lens features a longer focal length, allowing for a deeper focus and larger beam spot. This makes it especially effective when cutting thicker materials without losing too much beam quality. It still maintains reasonable engraving performance, making it a popular choice for users balancing both needs.

Recommended Materials: Thick wood panels, multi-layer acrylic, MDF, and compressed board.

Use Cases: Structural components, packaging inserts, model building, and signage.

Key Advantage: Better penetration and cutting depth while still offering fair engraving quality.

Limitation: Less effective for intricate engraving due to the larger spot size.

4. Using the 4.0″ Lens for Laser Cutting

With the longest focal length in this lineup, the 4.0-inch lens provides the deepest focus and widest beam diameter. It’s not typically used for standard engraving but excels in specific use cases that require more working distance or the ability to follow surface contours.

Recommended Materials: Thick foam, large acrylic blocks, uneven or curved surfaces like cylindrical objects.

Use Cases: Rotary engraving, deep etching, 3D object engraving, cutting thick foams or stacked materials.

Key Advantage: Extended depth of field enables consistent results on non-flat or thick materials.

Limitation: Beam is too wide for high-precision work and may result in a softer engraving finish.

Conclusion

Choosing the correct laser heads based on your processing goals—whether it’s high-resolution image engraving or cutting through dense materials—can make a significant difference in the final outcome. From the versatile standard head to specialized high-resolution and four types of lens options, each laser head brings its own advantages. By matching the laser head to your material and desired effect, you’ll ensure greater consistency, quality, and efficiency in your laser projects.

.png) International

International

United States

United States

Brasil

Brasil

Canada

Canada

Costa Rica

Costa Rica

Česká

Česká

Ελλάδα

Ελλάδα

Polska

Polska

Ireland

Ireland

Portugal

Portugal

Lietuva

Lietuva

Россия

Россия Deutschland

Deutschland

Britain

Britain

Україна

Україна

France

France

Sverige

Sverige

Italia

Italia

Norway

Norway

Denmark

Denmark

Romania

Romania

한국

한국

中国

中国

ประเทศไทย

ประเทศไทย

中国香港

中国香港

Israel

Israel

中國臺灣

中國臺灣

India

India

پاکستان

پاکستان

پශ්රී ලංකා

پශ්රී ලංකා

ジャパン

ジャパン

Australia

Australia

New Zealand

New Zealand

South Africa

South Africa